A kind of aromatic plant extract residue porous material and its application

A technology of aromatic plants and porous materials, applied in application, food science, other chemical processes, etc., can solve problems such as affecting taste and drying of cigarette smoke, and achieve the effects of improving moistness, sufficient sources and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

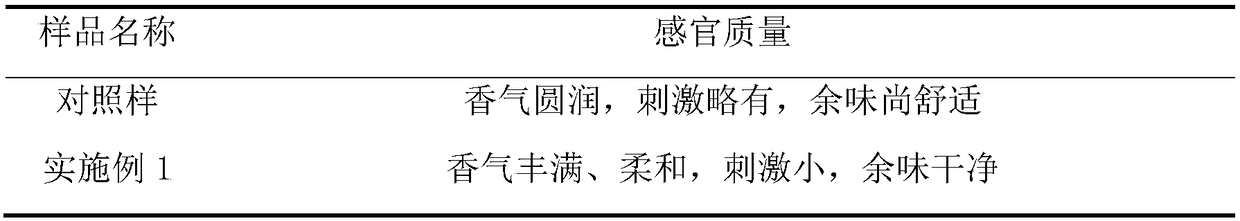

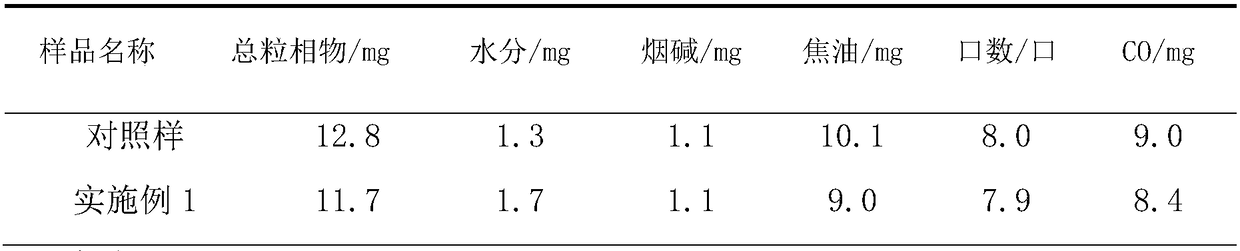

Embodiment 1

[0021] The residue after the extraction of aromatic plants described in this example is extracted with rosemary as raw material, the remaining residue is filtered, microwaved at a microwave power of 350W for 15min, and then the microwave-treated material is dried at 50°C and crushed After sieving, 20 mesh powder was obtained.

[0022] The preparation method of the residue porous material after aromatic plant extraction described in the present invention specifically comprises the following steps: 20 mesh rosemary extract residue powder is put into the tube together with KOH solid powder at a mass ratio of 1:3 In a type furnace, the temperature was raised to 500 °C at a rate of 10 °C / min in an argon atmosphere, and the temperature was kept for 15 min, followed by washing with 5% HCl to remove KOH, washing with distilled water until the pH value was neutral, and finally putting the material in Bake at 110°C until constant weight.

[0023] Select specific specifications of tow, ...

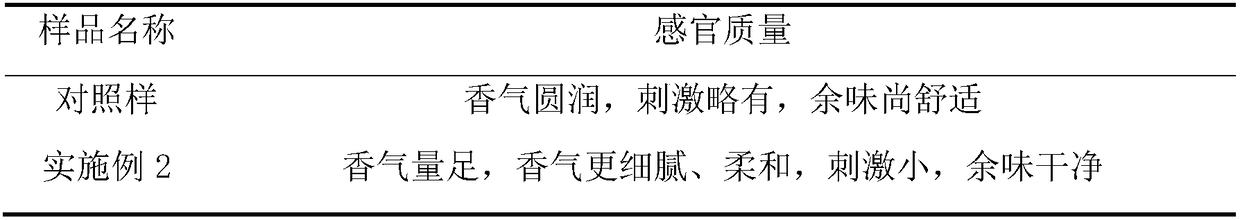

Embodiment 2

[0031] The residue after extraction of the aromatic plants described in this example is extracted from lavender, filtered, and microwaved at 500W for 10 minutes, then dried at 50°C, crushed and sieved to obtain a 40-mesh powder.

[0032] The preparation method of the residue porous material after aromatic plant extraction described in the present invention specifically comprises the following steps: the residue powder after the extraction of 40 mesh lavender is put into a tube furnace together with the KOH solid powder at a mass ratio of 1:2, and Under an argon atmosphere, heat up to 700°C at a rate of 20°C / min, keep it warm for 10 minutes, then wash with 10% HCl to remove KOH, wash with distilled water until the pH value is neutral, and finally dry the material at 150°C to constant weight.

[0033] Select specific specifications of tow, roll the porous material on the KDF-2E forming machine for rod rolling, select the specification tow on the KDF-2E forming machine to roll wh...

Embodiment 3

[0041] The residue after the extraction of the aromatic plants described in this example is extracted from the raw materials violet and lavender, the remaining residue is filtered, microwaved at a microwave power of 700W for 5 minutes, and then the microwave-treated material is dried at 70°C and crushed. Sieve to obtain 60 mesh powder.

[0042] The preparation method of the residue porous material after aromatic plant extraction described in the present invention specifically comprises the following steps: putting 60 mesh violet and lavender extract residue powder into a tube furnace together with KOH solid powder at a mass ratio of 1:6 , in an argon atmosphere at a heating rate of 15°C / min to 600°C, keep the temperature for 20min, then wash with 15% HCl to remove KOH, wash with distilled water until the pH value is neutral, and finally put the material at 120°C Bake to constant weight.

[0043] Select specific specifications of tow, roll the porous material on the KDF-2E for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com