Forming equipment for metal button and production method for forming equipment

A technology for forming equipment and buttons, which is applied in the direction of metal processing equipment, buttons, buttons, etc., can solve the problem of uneven thickness of buttons, achieve the effects of uniform thickness, increase appearance, and reduce temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

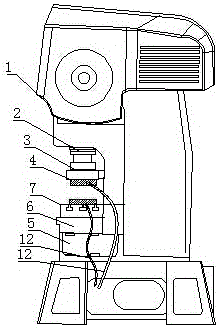

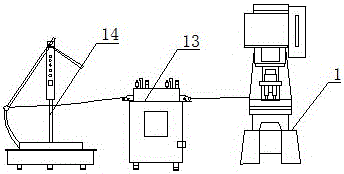

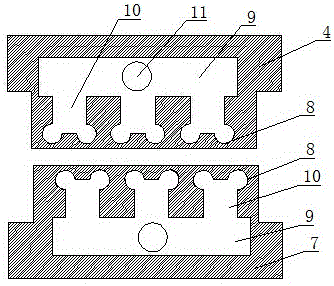

[0025] Reference attached Figure 1 to Figure 6 The embodiment of the molding equipment of a kind of metal button of the present invention and its production method is described further:

[0026] Reference attached figure 1 with attached figure 2 , a metal button forming device, connected with a roller feeder 13, including a bracket 1 and an upper mold and a lower mold matched up and down on the bracket 1, the upper mold includes an upper template 2, and the lower mold of the upper template 2 An upper splint 3 is provided, a punch 4 is provided below the upper splint 3, the lower die includes a 5, a backing plate 6 is provided above the bottom plate 5, and a stretching die is provided on the backing plate 6 7. The inside of the drawing die 7 is provided with a cooling device, and the two outer sides of the support 1 are provided with water guide pipes 12 connected to the cooling device. Refer to the attached image 3 , the male die 4 is provided with a cooling device 2 sym...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap