Overlapping type combined forging method

A technology of sleeve forging and forging, applied in the field of superimposed sleeve forging process, can solve the problems of inability to apply the sleeve forging process, easy to produce deformation, increase the correction process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Several specific embodiments of the present invention are introduced below.

[0055] According to the structure of the parts, different superimposition methods of sleeve forgings are used to design a complete set of forgings. In order to improve the utilization rate of materials, closed forging can be used for sleeve forging.

[0056] 1) Example of plane superimposed sleeve forging

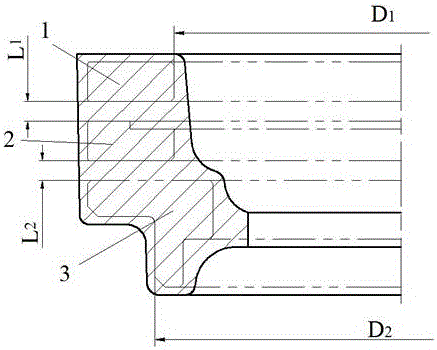

[0057] figure 1 The medium and large parts A1 and B2 are the combined ring gears of the second and third gears of a certain transmission, and the small parts A3 are the combined ring gears of the first gear, among which, 1 is the large part A, 2 is the large part B, and 3 is the small part A; D 1 is the inner diameter of large parts A and B, D 2 is the outer diameter of the boss of small part A, L 1 is the axial distance between large parts A and B, L 2 is the axial distance between large part B and small part A.

[0058] The material of the three is 20CrMoH, and the heat treatment h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com