Cleaning and temporarily storing method for accurately machined workpieces

A workpiece, the same technology, applied in the field of workpiece storage device, can solve the problems of cemented carbide scrap, easy to bruise, low efficiency, etc., to achieve the effect of avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

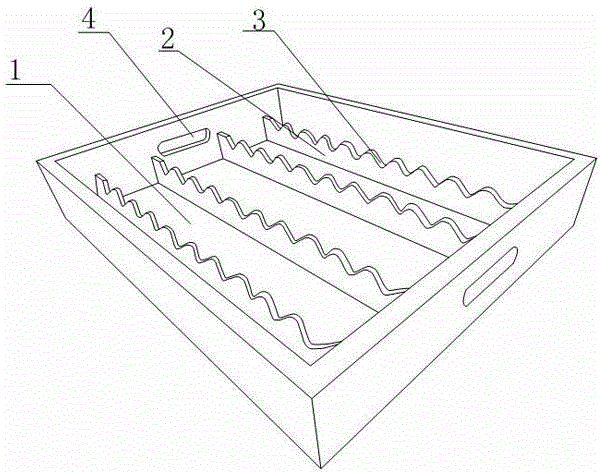

[0018] Such as figure 1 As shown, a method for cleaning and temporarily storing finished workpieces in the present invention includes a cuboid storage box 1 as a whole, the storage box 1 has a bottom surface and four sides, and handling holes 4 are provided on the two opposite sides. , four storage racks 2 parallel to each other are arranged on the bottom surface of the storage box 1, both ends of the storage racks 2 are connected to the sides of the storage box 1, and the bottom of the storage rack 2 is connected to the bottom surface of the storage box 1, The storage racks 2 are all perpendicular to the side where the carrying hole 4 is located, the four sides of the storage box 1 are of the same height and the height is greater than the height of the storage rack 2, and the upper surface of the storage rack 2 is sunken downwards to form a plurality of grooves 3, four The groove 3 at the same position on the storage rack 2 forms an arc-shaped storage groove. The bottom and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com