Novel electrotyping anti-vibration treatment process

A treatment process and electric engraving technology, which is applied in printing and plate preparation, etc., can solve the problems of plate roll tube arm thin plate roll, easy to take out, difficult to remove, and low efficiency, so as to improve work efficiency, good shockproof effect, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

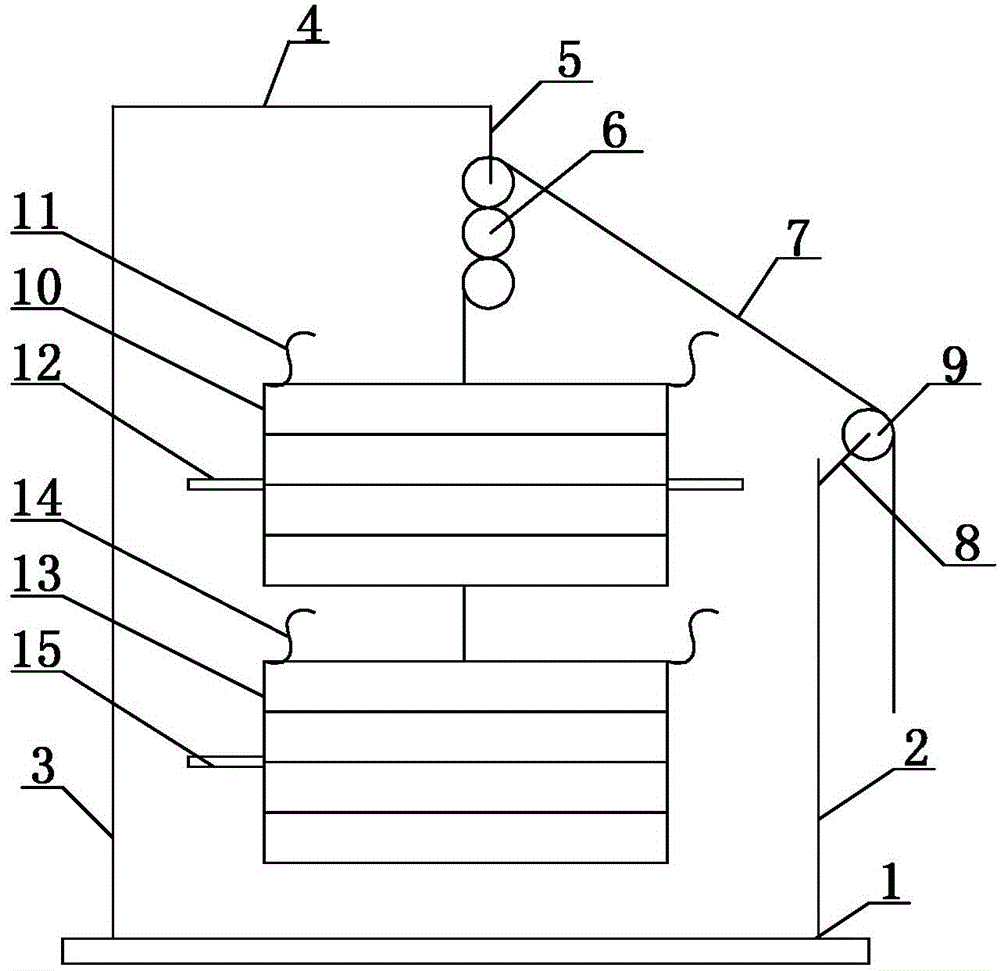

[0013] Such as figure 1 As shown, an electric carving anti-vibration copper chip bag device includes a base plate 1 on which a first side plate 2 and a second side plate 3 are arranged, and the first side plate 2 and the second side plate 3 are vertically arranged. The first side plate 2 and the second side plate 3 are arranged in parallel, the end of the second side plate 3 is provided with a top plate 4, the top plate 4 is arranged horizontally, and the end of the top plate 4 is provided with a connecting rod 5, and the connecting rod 5 is vertical. Arranged straight, the connecting rod 5 is provided with a fixed pulley 6, which is composed of three wheels of the same shape and size connected sequentially from top to bottom, the fixed pulley 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com