Longitudinal tear detection device and method for conveying belt

A technology of longitudinal tearing and detection device, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of high labor intensity, long detection time, physical damage to the detection personnel, etc., to achieve good protection, The effect of reducing maintenance time and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

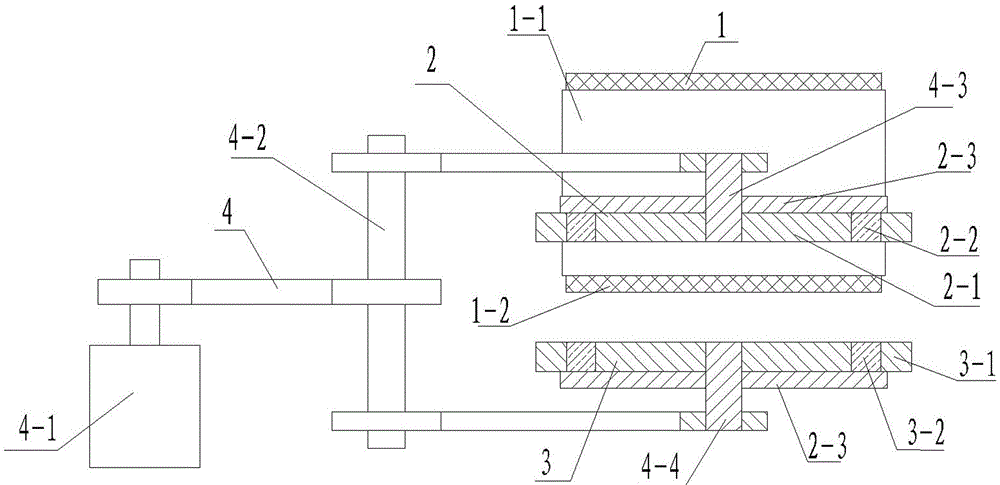

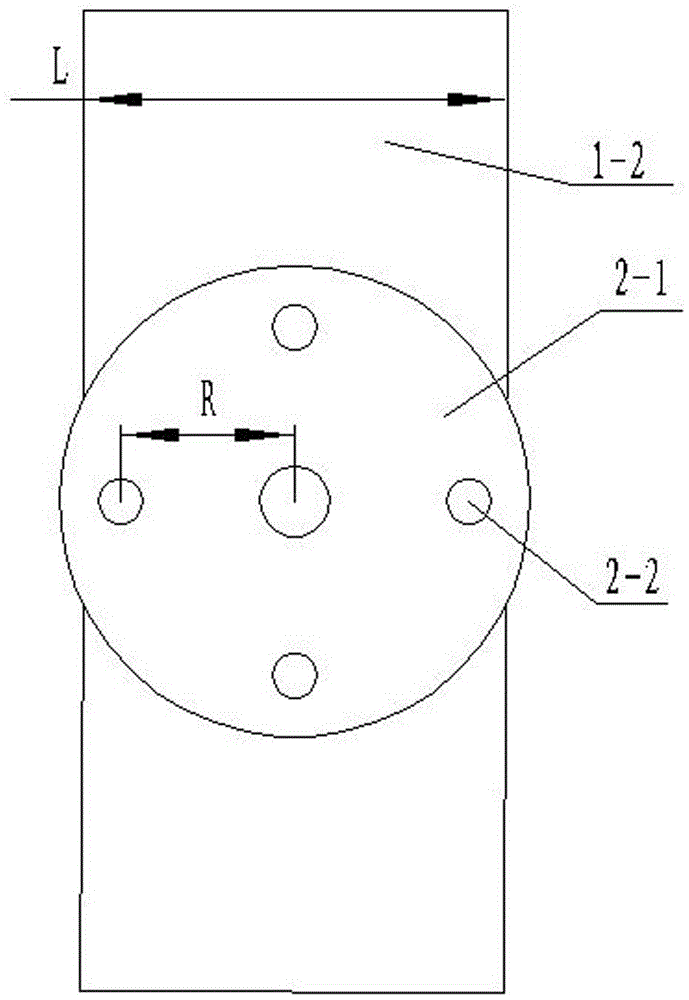

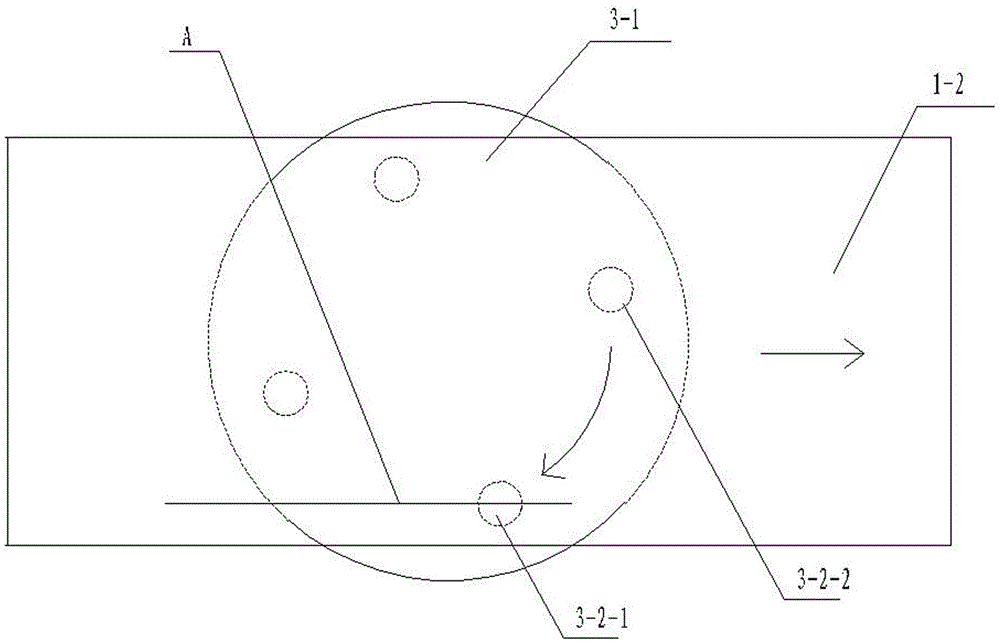

[0033] See attached Figure 1-8 , a conveyor belt longitudinal tear detection device, including a signal transmitting unit 2 arranged on the upper and lower sides of the lower belt 1-2 of the conveyor belt 1, a signal receiving unit 3 and a supporting calculation, analysis and processing unit, the signal transmitting unit 2 includes The transmitting end mounting plate 2-1 connected to the synchronous driving mechanism 4 and the X-ray tube 2-2 arranged on the transmitting end mounting plate 2-1, the signal receiving unit 3 includes a receiving end mounting plate connected to the synchronous driving mechanism 4 The board 3-1 and the X-ray receiver 3-2 arranged on the receiving end mounting board 3-1 and matching with the X-ray tube 2-2, the X-ray tube 2-2 and the X-ray receiver 3-2 The synchronous movement is realized by means of the synchronous drive 4 .

[0034] See attached Figure 1-6 According to Embodiment 1 of the present invention, the transmitting end mounting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com