A simple and convenient method for preparing calcium carbonate hollow microspheres

A kind of hollow microsphere, calcium carbonate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

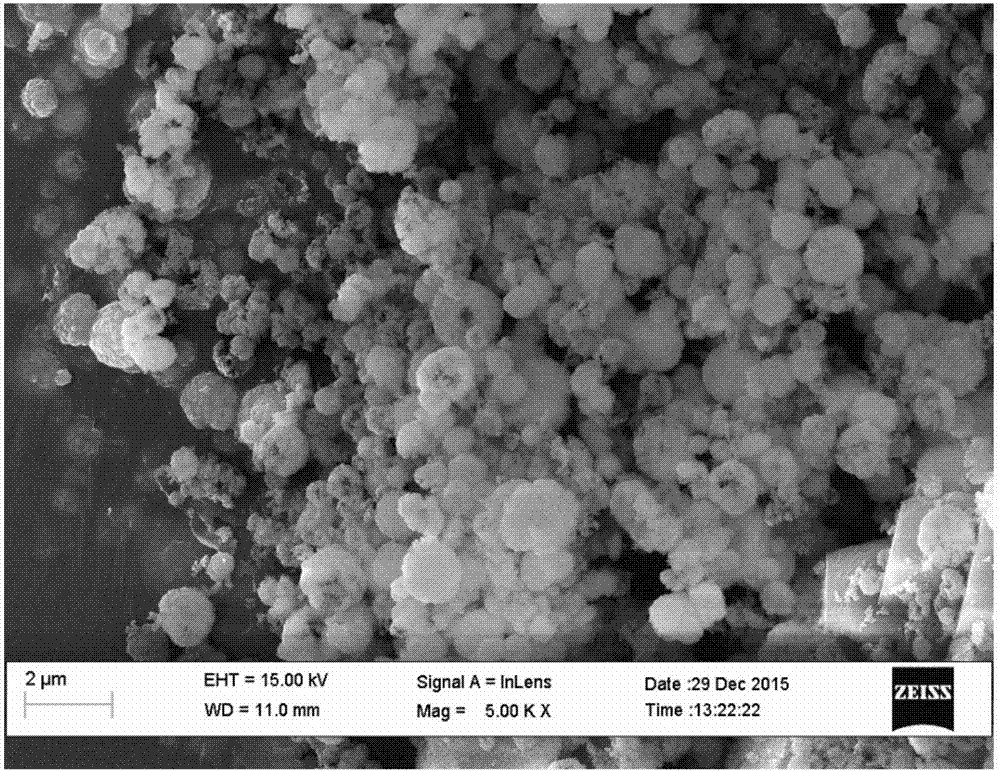

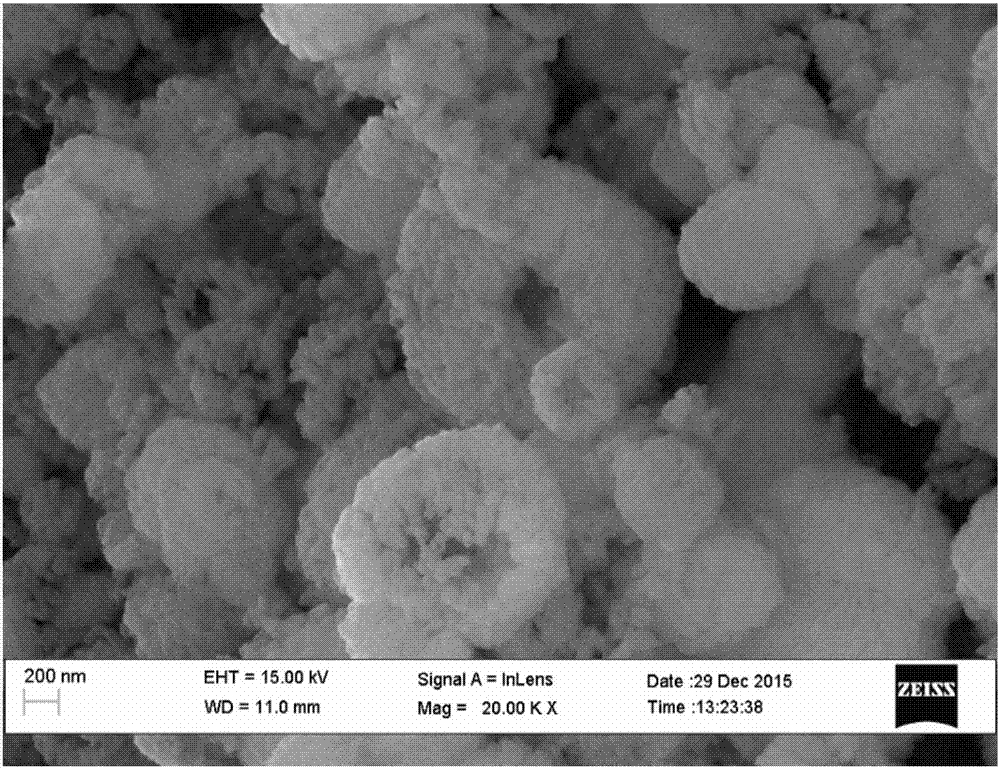

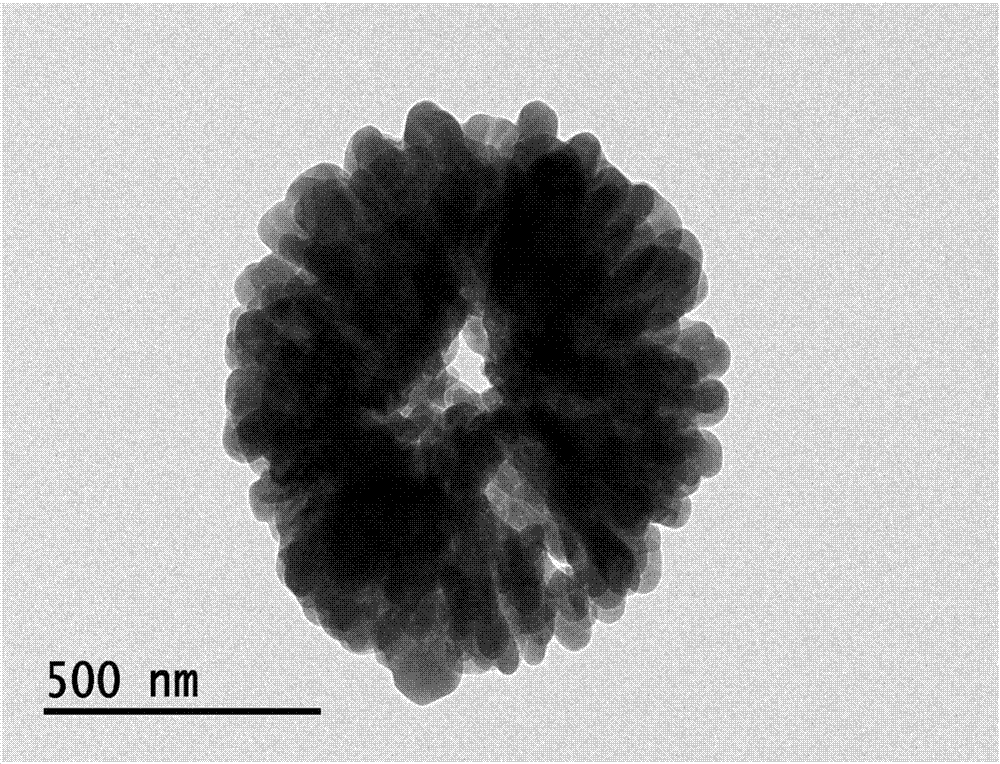

[0012] Embodiment 1: in the 50ml beaker, the sodium bicarbonate aqueous solution of 0.18mol / L and the calcium chloride ethanol solution of 0.18mol / L are respectively configured, and the solution is filtered and purified by 0.45 μm membrane, and then two kinds of the same volume Mix the solution, shake it quickly to make it gel, wait for 40 to 80 minutes to hydrate the gel, centrifuge the resulting precipitate, take the precipitate and wash it alternately with twice distilled water and absolute ethanol, and dry it at 100°C to obtain a calcium carbonate hollow Microspheres. The product obtained by the invention is a hollow calcium carbonate microsphere with a particle size of 400-800nm.

Embodiment 2

[0013] Example 2: 0.14mol / L sodium bicarbonate aqueous solution and 0.14mol / L calcium chloride ethanol solution were respectively configured in a 50ml beaker, and the solution was filtered and purified through a 0.45 μm filter membrane, and then the same volume of the two Mix the solution, shake it quickly to make it gel, wait for 40 to 80 minutes to hydrate the gel, centrifuge the resulting precipitate, take the precipitate and wash it alternately with twice distilled water and absolute ethanol, and dry it at 100°C to obtain a calcium carbonate hollow Microspheres. The product obtained by the invention is a hollow calcium carbonate microsphere with a particle size of 400-800nm.

Embodiment 3

[0014] Embodiment 3: configure respectively 0.1mol / L sodium carbonate aqueous solution and 0.1mol / L calcium chloride ethanol solution in a 50ml beaker, the solution is filtered and purified through a 0.45 μm filter membrane, and then two kinds of solutions of the same volume Mix and oscillate quickly to form a gel, wait for 40 to 80 minutes for the gel to hydrate, centrifuge the resulting precipitate, take the precipitate and alternately wash it with twice distilled water and absolute ethanol, and dry it at 100°C to obtain a hollow calcium carbonate microsphere. ball. The product obtained by the invention is a hollow calcium carbonate microsphere with a particle size of 400-800nm.

[0015] In each embodiment of the present invention, the rapid oscillation is to use a vortex mixer to oscillate for 4-7s, and the frequency of vibration of the vortex mixer is 2800 times / min. As a change, other oscillating equipment or hand shaking can also be used, as long as the mixed solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com