A circulating type anticorrosion automatic water supplementing system

A technology of automatic water replenishment and water pipes, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problem of corrosion of circulation equipment and circulation pipelines, affecting equipment performance, Shorten the service life of equipment and other issues, to achieve the effect of prolonging service life, protecting from corrosion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

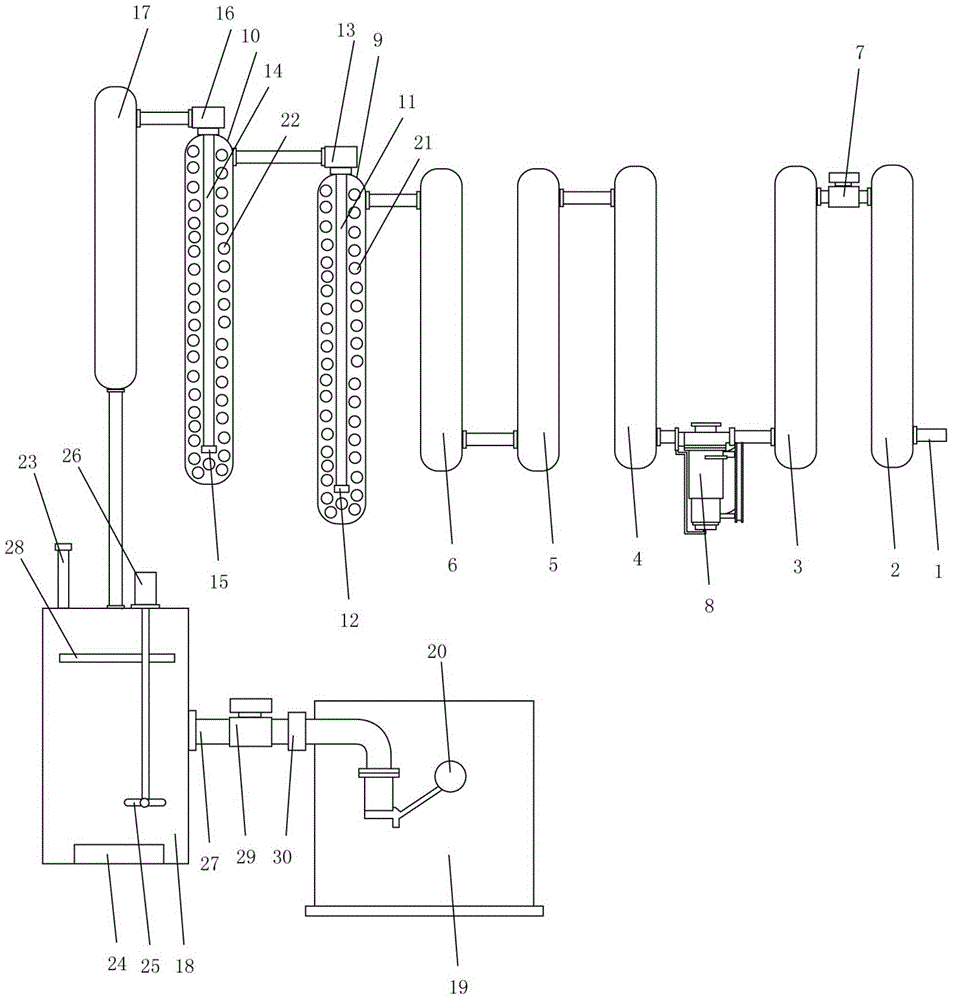

[0021] Such as figure 1 As shown, an anti-corrosion automatic water replenishment device includes a water inlet pipe 1, a first PP cotton filter 2, a second PP cotton filter 3, a precision activated carbon filter 4, a silver-loaded activated carbon filter 5, and a third PP cotton filter 6. Control valve 7, water pump 8, anion exchange resin filter 9, cation exchange resin filter 10, anion exchange resin upper water pipe 11, anion exchange resin filter membrane 12, anion exchange resin outlet valve 13, cation exchange resin upper water pipe 14 , cation exchange resin filter membrane 15, cation exchange resin outlet valve 16, the fourth PP cotton filter 17, deaerator 18, water storage tank 19, ball float valve 20, the first PP cotton filter 2, the second PP cotton filter Device 3, precision activated carbon filter 4, silver-loaded activated carbon filter 5, and the third PP cotton filter 6 are connected in sequence, the water inlet pipe 1 is connected to the first PP cotton filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com