A belt cushion rubber for all-steel radial truck tires capable of improving tire shoulder clearance

A radial tire and belt layer technology, applied in the field of rubber, can solve problems such as poor tire overload resistance, reduced tire service life, and reduced tire quality, and achieve improved tire durability, improved processing performance, and improved tire wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

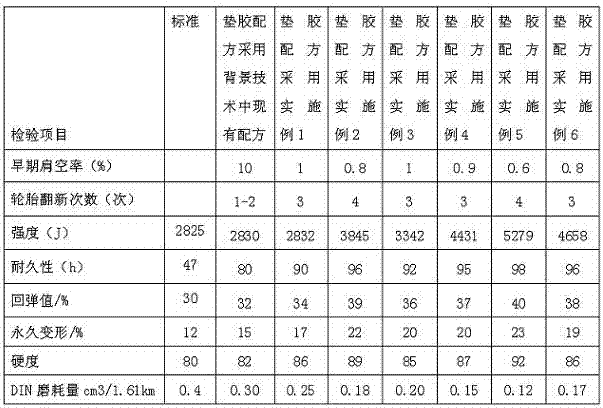

Examples

Embodiment 1

[0013] Embodiment 1, a kind of all-steel radial tire belt cushion rubber that can improve tire shoulder space, is made up of the raw material of following parts by weight: SMR10# 80 parts, carbon black N326 25 parts, white carbon black 5 parts, liquid iso 0.8 parts of pentamethylene rubber, 2 parts of zinc oxide, 0.5 parts of stearic acid, 1 part of silane coupling agent Si69, 0.7 parts of dispersant FNS-78T, 1 part of 204 resin, 0.5 parts of anti-aging agent 6PPD, 0.5 parts of microcrystalline wax, anti-aging Agent TMQ 0.4 parts;

[0014] The nano-zinc oxide includes primary particles with a particle size of 80nm or less and primary particles with a particle size of 80nm-100nm, wherein primary particles with a particle size of 80nm or less account for 80%, and primary particles with a particle size of 80nm-100nm account for 20%. %.

Embodiment 2

[0015] Embodiment 2, a kind of all-steel radial tire belt cushion rubber that can improve tire shoulder space, is made up of the raw material of following parts by weight: SMR10# 100 parts, carbon black N326 34 parts, white carbon black 10 parts, liquid iso 2 parts of pentamethylene rubber, 5 parts of nano zinc oxide, 2 parts of stearic acid, 2 parts of silane coupling agent Si69, 1.5 parts of dispersant FNS-78T, 2 parts of 204 resin, 1.5 parts of anti-aging agent 6PPD, 1 part of microcrystalline wax, Anti-aging agent TMQ 1 part;

[0016] The nano-zinc oxide includes primary particles with a particle size of 80nm or less and primary particles with a particle size of 80nm-100nm, wherein primary particles with a particle size of 80nm or less account for 80%, and primary particles with a particle size of 80nm-100nm account for 20%. %.

Embodiment 3

[0017] Embodiment 3, a kind of all-steel radial tire belt cushion rubber that can improve tire shoulder space, is made up of the raw material of following parts by weight: SMR10# 120 parts, carbon black N326 240 parts, white carbon black 15 parts, liquid iso 3.2 parts of pentamethylene rubber, 8 parts of zinc oxide, 3.5 parts of stearic acid, 3 parts of silane coupling agent Si69, 2.3 parts of dispersant FNS-78T, 3 parts of 204 resin, 2.5 parts of anti-aging agent 6PPD, 1.5 parts of microcrystalline wax, anti-aging Agent TMQ 1.6 parts;

[0018] The nano-zinc oxide includes primary particles with a particle size of 80nm or less and primary particles with a particle size of 80nm-100nm, wherein primary particles with a particle size of 80nm or less account for 80%, and primary particles with a particle size of 80nm-100nm account for 20%. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com