Low VOC content tread rubber material and manufacturing method and application thereof

A technology of tread rubber and content, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as difficult to control volatile organic compounds, and achieve the effect of reducing the VOC value and atomization value of the rubber compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

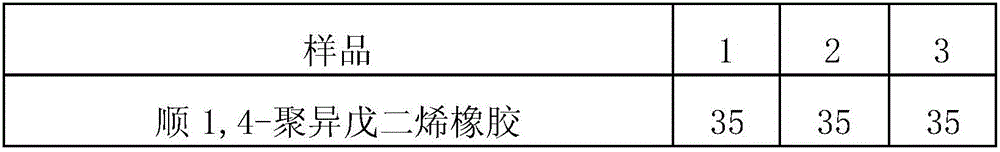

[0049] Tread compounds with the composition specified in Table 1 were prepared in a GK400 internal mixer in four separate addition mixing stages, namely, three non-productive mixing stages and one productive mixing stage. The three non-productive stages were mixed for about 1-3 minutes until the rubber temperature reached 160°C; the mixing time for the productive stage was to make the rubber temperature reach 115°C, about 1-2 minutes.

[0050] The specific process is as follows:

[0051] The rubber main material (cis 1,4-polyisoprene rubber, cis-butadiene-trans-butadiene copolymer synthetic rubber, styrene-butadiene copolymer synthetic rubber) and aromatic oil are subjected to 1.5~ 4 minutes of non-productive mixing until the temperature of the rubber material reaches 160 ° C, that is to say, it is completed;

[0052] After one-stage degumming and cooling, add carbon black, anti-aging agent (anti-aging agent 6PPD, anti-aging agent TMQ, protective wax) and stearic acid to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com