A dry distillation incinerator for oil shale dry distillation and shale semi-coke combustion

An oil shale and incinerator technology, which is applied in coke ovens, incinerators, combustion methods and other directions, can solve the problems of insufficient utilization of semi-coke, inability to effectively use the process flow, and low oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

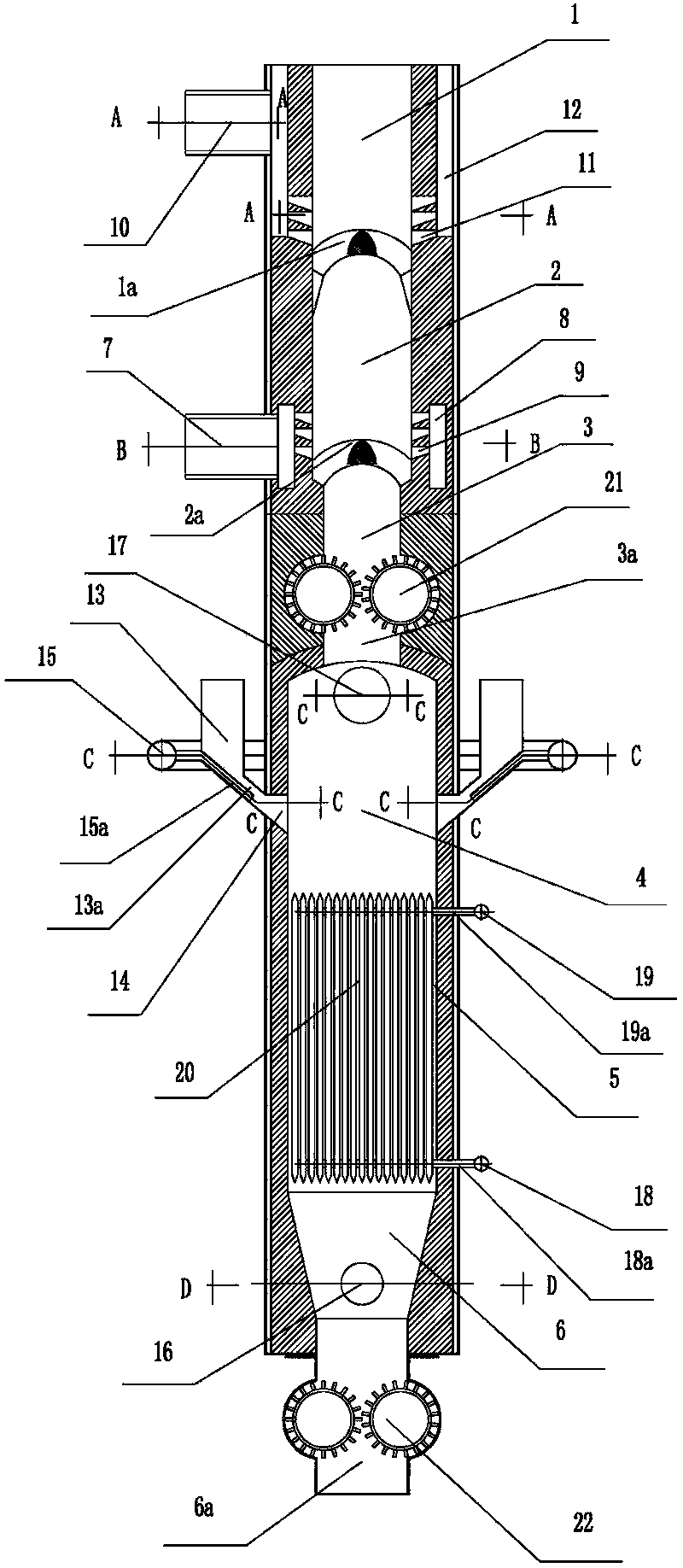

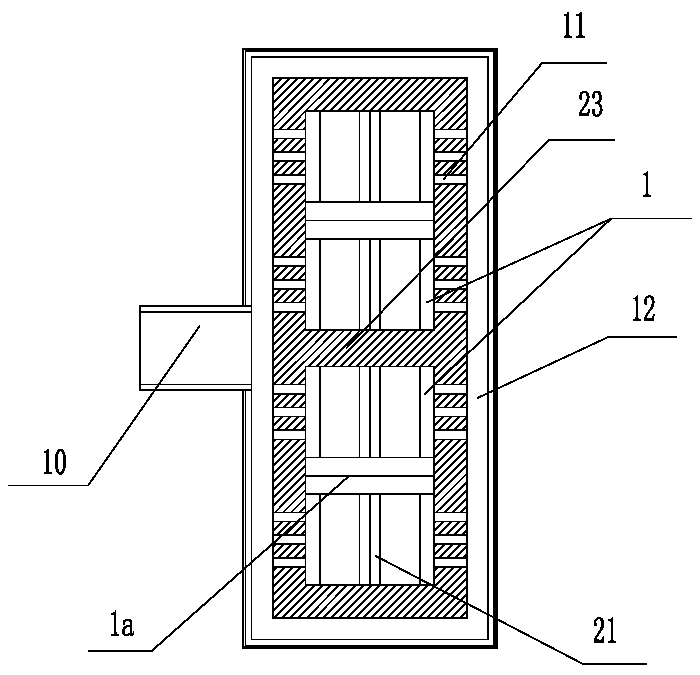

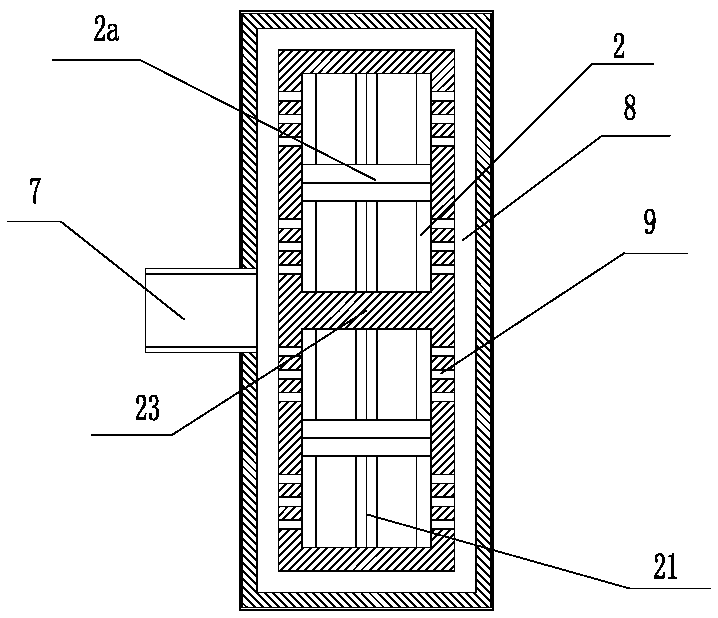

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as Figure 1-Figure 5 As shown, the dry distillation incinerator of the present invention is a rectangular cylinder, and the rectangular cylinder is composed of interconnected shale preheating chamber 1, shale dry distillation chamber 2, semi-coke diversion chamber 3, semi-coke The incineration chamber 4, the ash cooling chamber 5 and the ash discharge chamber 6 are composed. The wall of the shale preheating chamber 1 is provided with a retort gas collection channel 12 in the circumferential direction, and the inner wall of the retort gas collection channel (near the shale preheating The inner wall of the shale preheating chamber) has a retort gas collection port 11 connected to the shale preheating chamber, and the upper part of the outer wall of the retort gas collection channel (close to the outer wall of the shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com