Operation method of distillation cooling production system for mulberry wine

A technology of production system and operation method, which is applied in the field of distillation and cooling production system of mulberry wine, can solve problems such as difficult to achieve higher purity alcohol content, increase production cost of enterprises, reduce production efficiency, etc., achieve ideal purification effect and reduce production cost Inexpensive and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

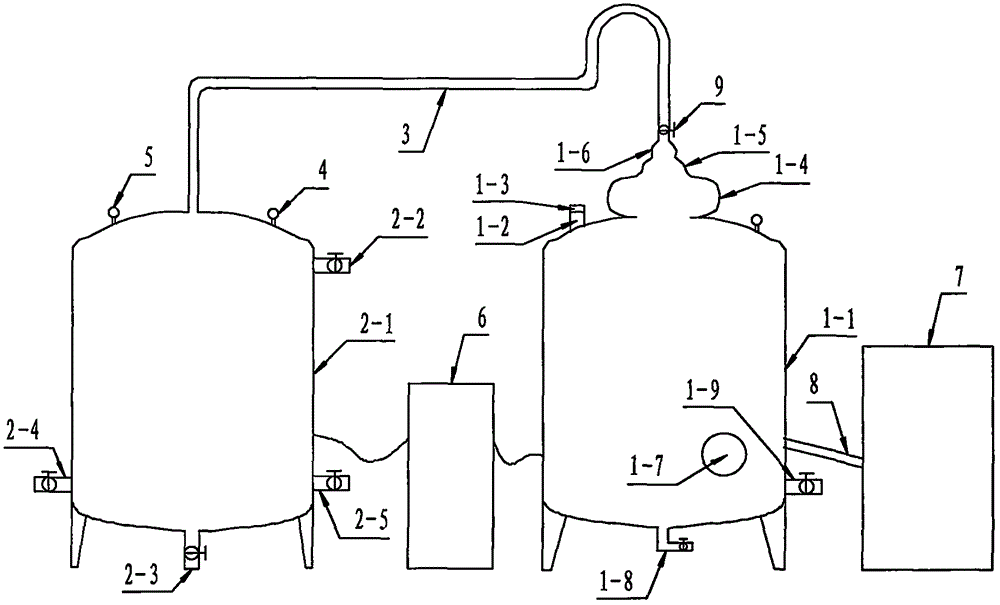

[0021] A pressure and temperature control box 6 is set between the distiller and the cooling tower, a steam generator 7 is set on the other side of the distiller, a steam transmission pipe 8 is set between the steam generator 7 and the bottom of the distiller, and the pressure and temperature control box 6 is respectively connected to the distiller. , Set wires between cooling towers;

[0022] The structure of the distiller is as follows: the bottom surface and the top surface of the distillation tank 1-1 are all set as spherical surfaces, one side of the top surface is provided with a feed port 1-2, and the other side is provided with a pressure gauge 4, and the feed port 1-2 is provided with a pressure gauge 4. 2. A sealing cover 1-3 is arranged on the top, a pumpkin-shaped steam collector 1-4 is arranged on the air outlet corresponding to the center above the top surface, and an intermediate condenser 1 is arranged between the top of the steam collector 1-4 and the top conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com