Supporting position self-regulation type hydraulic support device

A hydraulic support and self-adjusting technology, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problem that the support effect cannot meet the support requirements for the stability of the shearer fuselage, no support system is set, and the fuselage is stable Poor performance and other problems, to achieve the effect of simple installation, layout and operation, good support effect and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

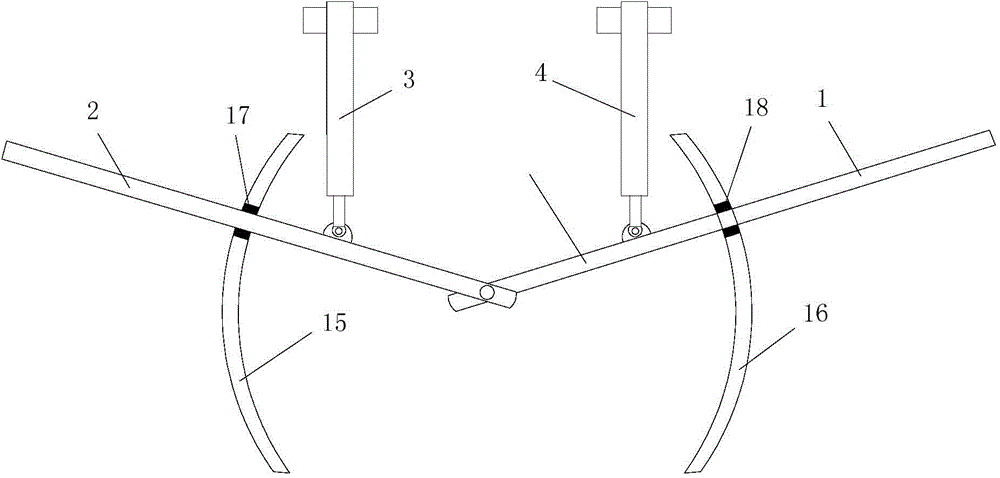

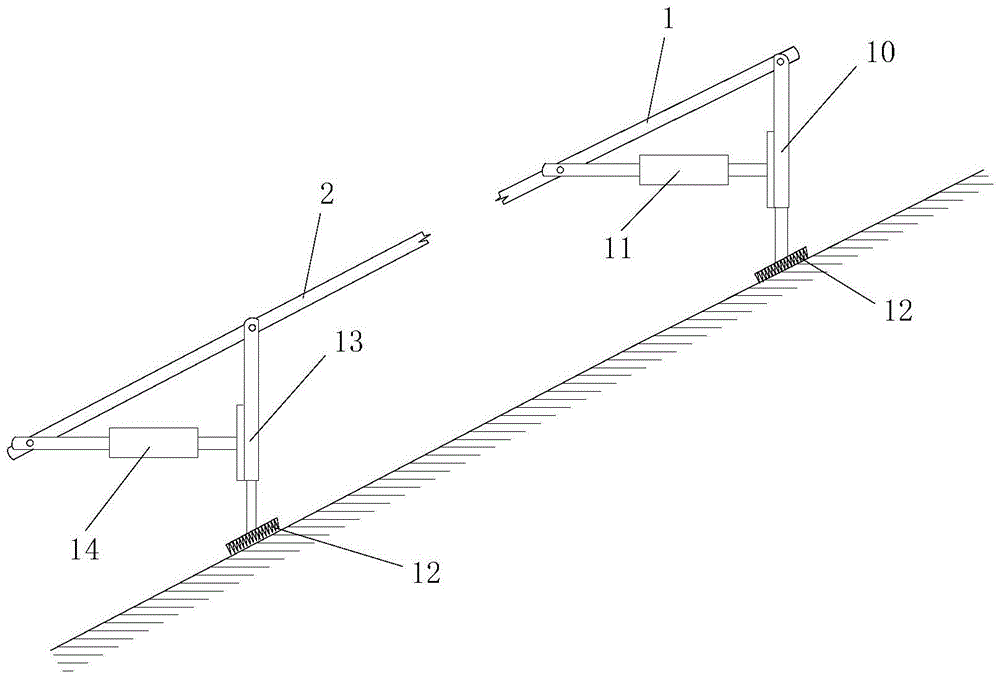

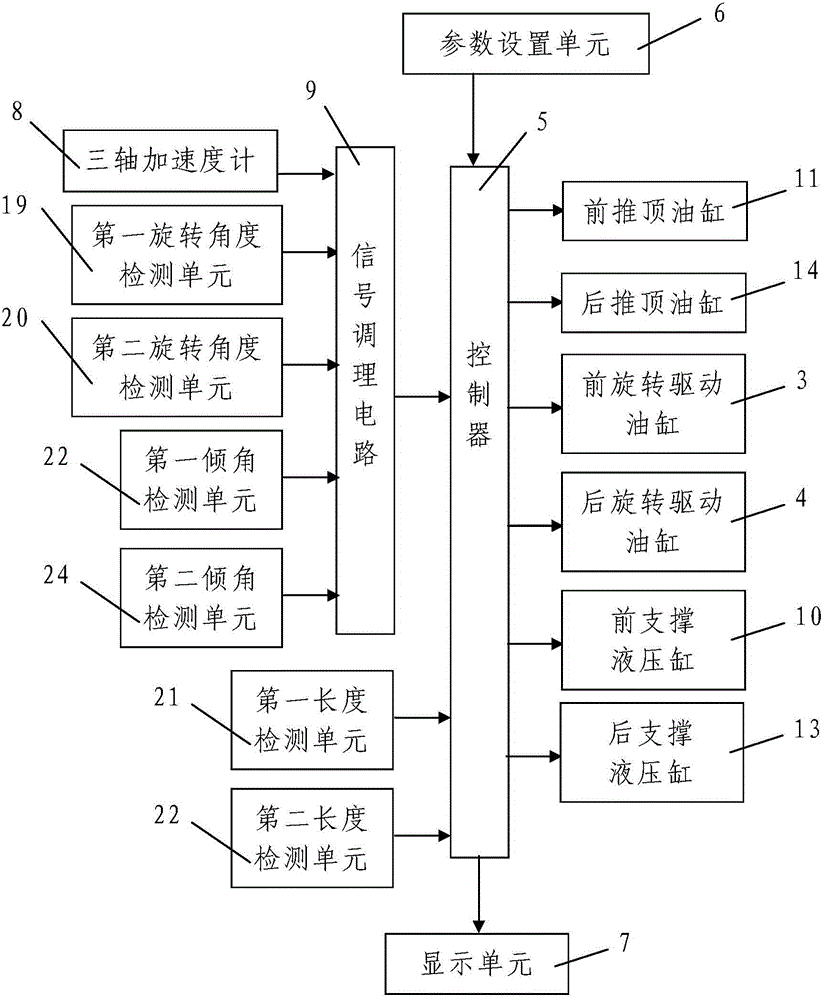

[0032] Such as figure 1 , figure 2 and Figure 4As shown, the present invention includes an inclination angle detection unit for detecting the inclination angles of the supported shearer fuselage on the X, Y and Z axes, and a forward slide arranged on the upper part of the front side of the supported shearer fuselage. Moving beam 1, the front hydraulic support mechanism installed under the front side of the front sliding beam 1, the rear sliding beam 2 arranged on the rear upper part of the supported coal shearer fuselage, installed on the rear side of the rear sliding beam 2 The lower rear hydraulic support mechanism drives the front sliding beam 1 to rotate left and right and adjusts the support position of the front hydraulic support mechanism accordingly. The front rotary drive cylinder 3 drives the rear sliding beam 2 to rotate left and right and correspondingly The rear rotary drive cylinder 4 that adjusts the support position of the rear hydraulic support mechanism a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com