A metal belt type continuously variable transmission and method for controlling the speed of mechanical transmission by motor

A continuously variable transmission and mechanical transmission technology, applied in the field of automobile transmission, can solve the problems of the CVT cannot be repaired but can only be replaced as a whole, the structure of the CVT is complicated, the advantages of fuel saving are weakened, etc., so as to reduce the maintenance difficulty and facilitate the disassembly. Installation and maintenance, good production inheritance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

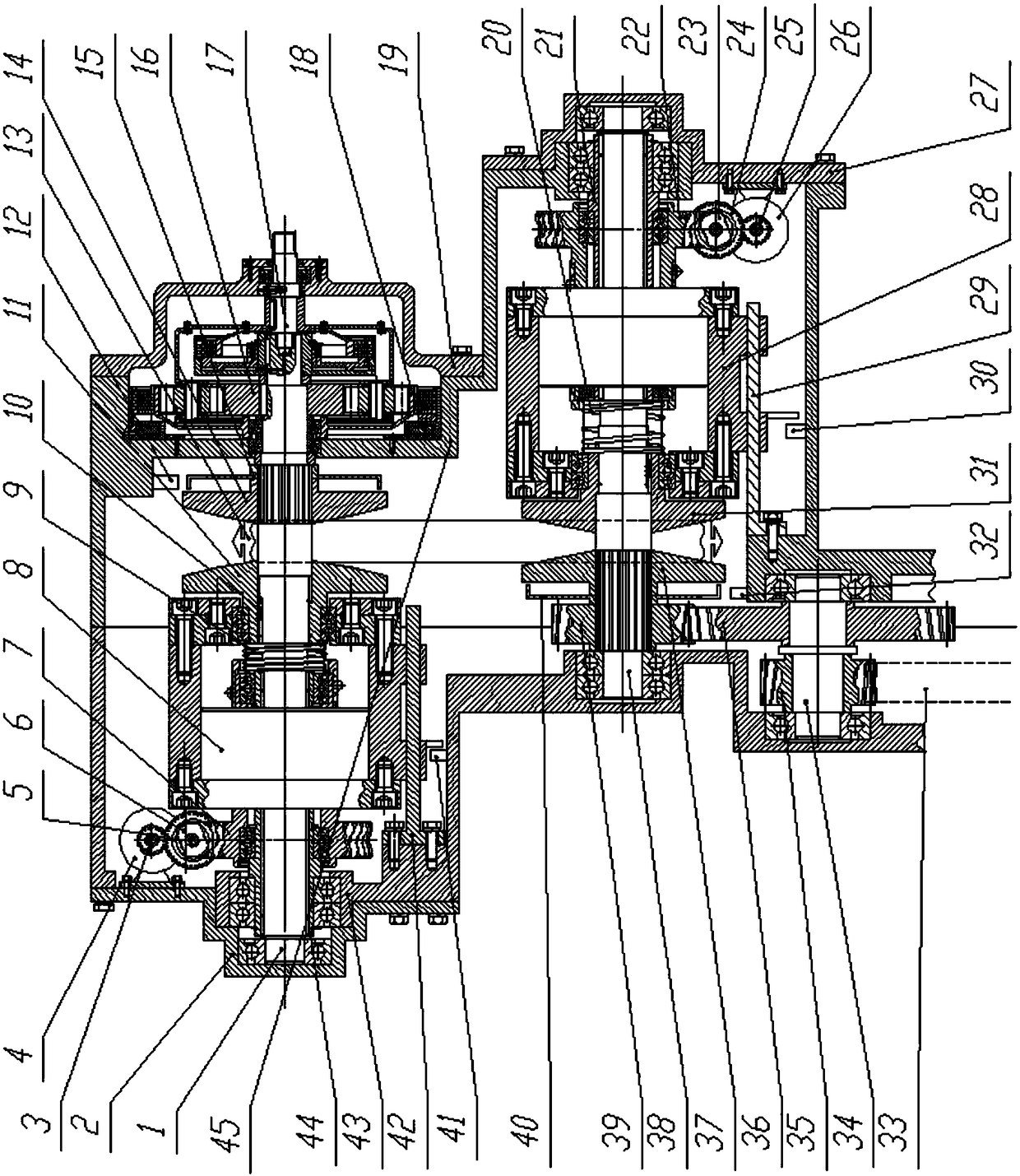

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0062] Such as figure 1 As shown, the motor-controlled mechanical transmission speed-regulating metal belt type continuously variable transmission provided by the present invention includes:

[0063] The drive shaft 1 is rotatably supported on the transmission housing 2 through bearings, and is used to receive the rotational power of the engine or the motor, and the drive hollow shaft 44 is sheathed on the outside;

[0064] The driven shaft 38 is rotatably supported on the transmission housing 27 through bearings for outputting rotational power, and the driven hollow shaft 21 is sheathed on the outside; and

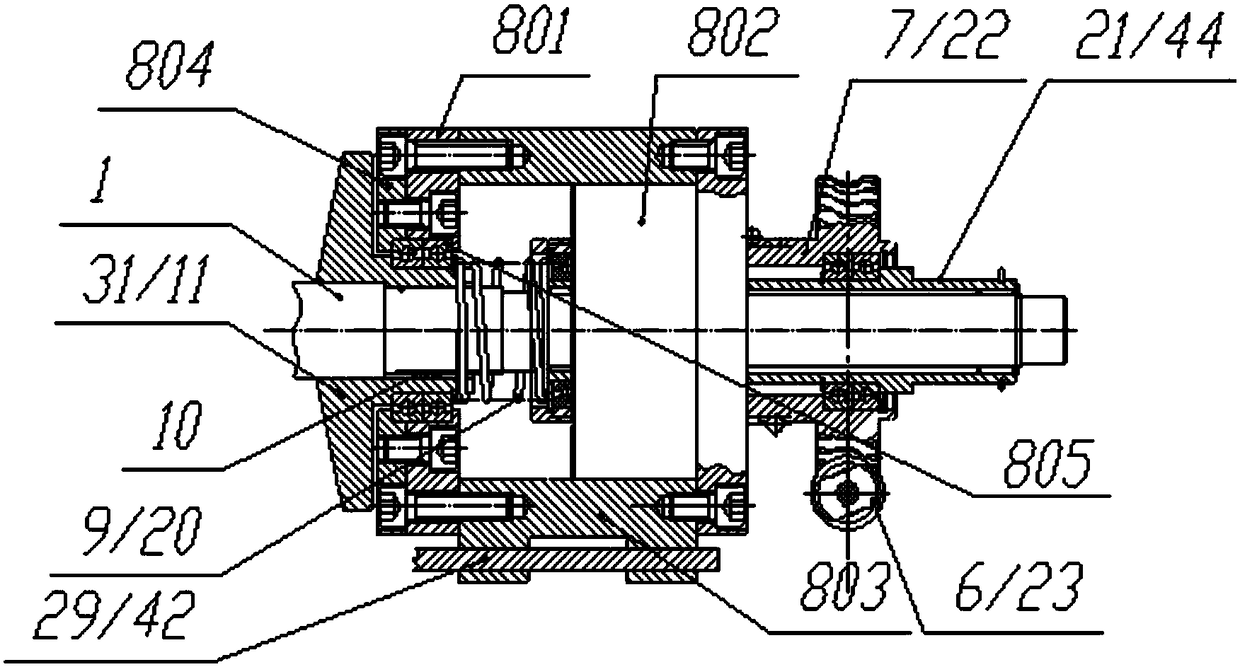

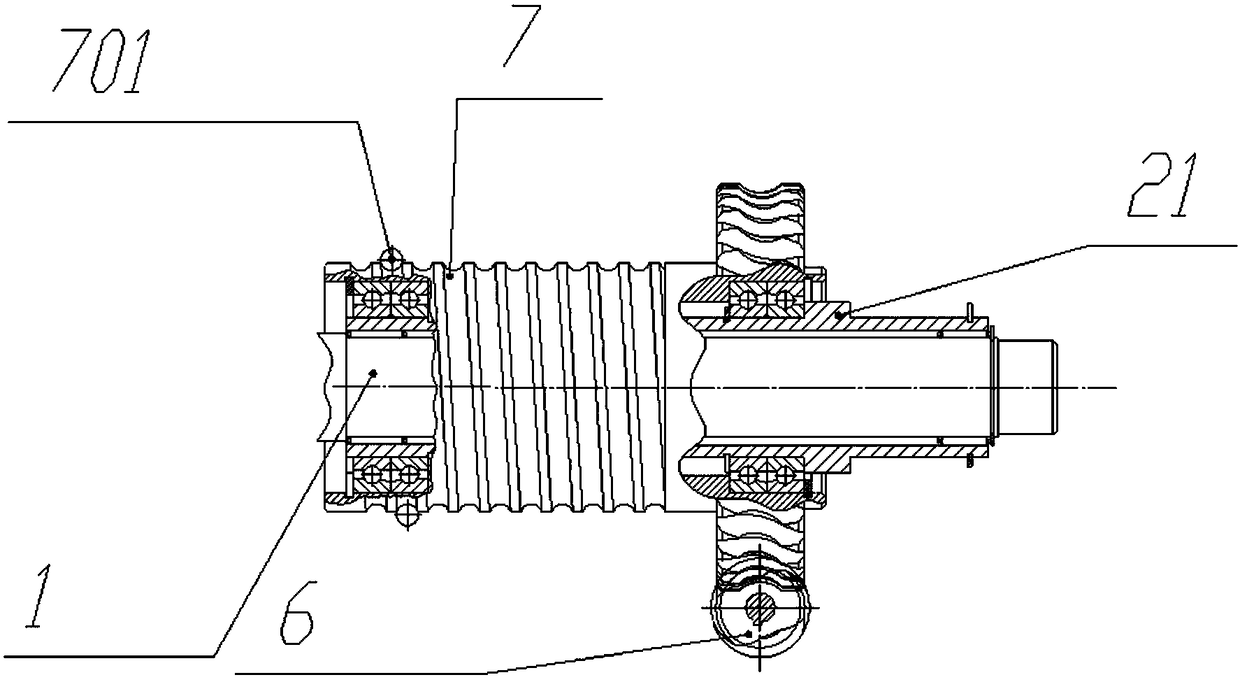

[0065] The first screw shaft 7 is hollow inside and has a hemispherical ball raceway on its outer surface, and is rotatably supported on the driving shaft 1 through bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com