Draining device for high-pressure heater regulating valve

A high-pressure heater and regulating valve technology, which is applied to steam traps, mechanical equipment, etc., can solve problems such as large impact on economy and safety, unsmooth drainage, and damage to regulating valves, and achieves simple structure and flow capacity. Strong and short maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

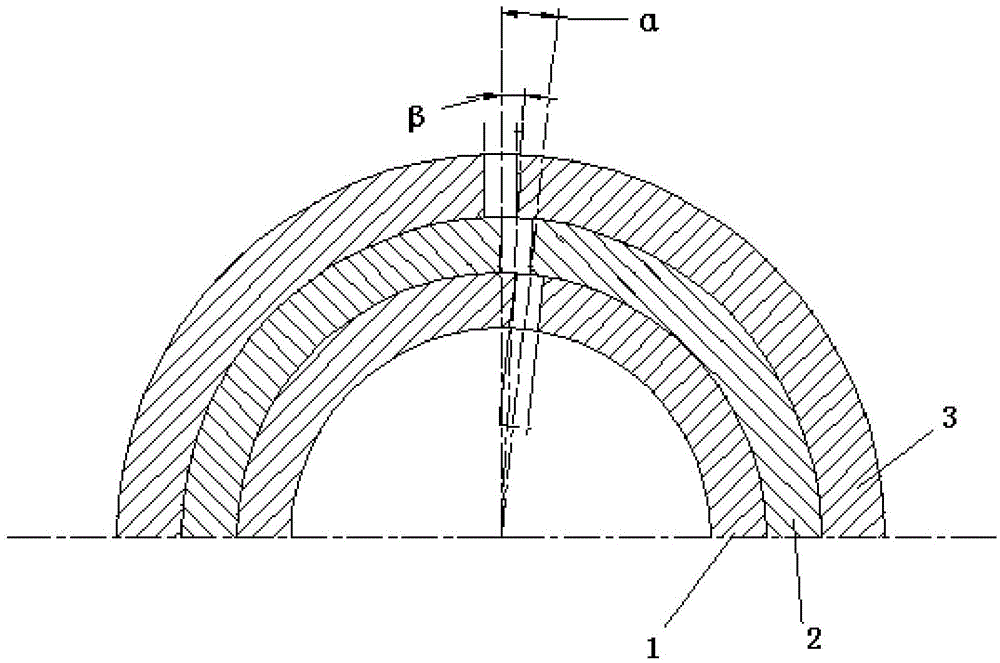

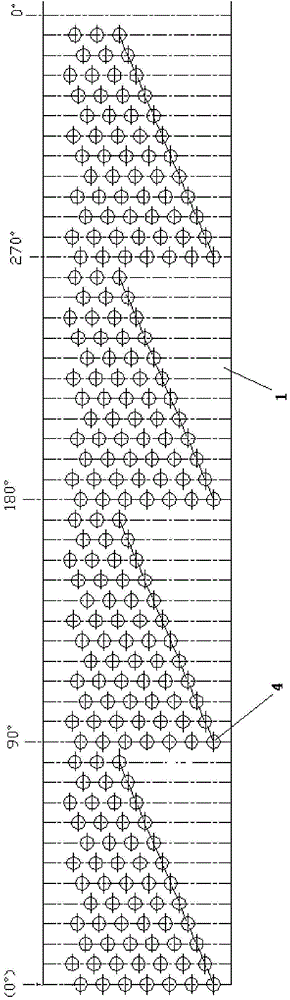

[0024] Such as figure 1 As shown in the figure, a drainage device for regulating valves of high-pressure heaters is composed of an inner cage 1, a middle cage 2 and an outer cage 3, and the middle cage 2 and the outer cage 3 are set in turn. Set on the inner valve cage 1. The multiple flow holes 4 on each layer of valve cages are divided into 4 repeating groups on average, and each repeating group corresponds to a 1 / 4 circle of the valve cage. There are 59 flow holes 4 in each repeating group, and the flow holes 4 It is divided into 12 columns at equal intervals, and the number is increased every 2 columns or every 3 columns. Wherein, the diameter of the flow hole 4 increases layer by layer from the inside to the outside.

[0025] In this embodiment, the hole diameter of the flow hole 4 of the inner cage 1 is 5 mm, the diameter of the flow hole 4 of the middle cage 2 is 5.5 mm, and the diameter of the flow hole 4 of the outer cage 3 is 6 mm. The center-to-center distance be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com