Maleic anhydride reaction cooling device

A cooling device and reaction technology, used in steam/steam condensers, lighting and heating equipment, heat exchange equipment, etc., can solve problems such as low efficiency, increased production costs, general cooling effect of coolers, etc., to optimize space configuration, Optimized cooling effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

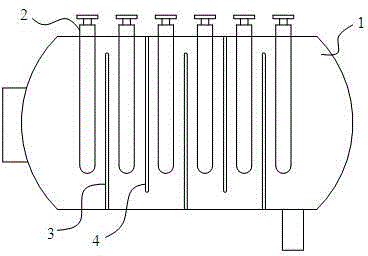

[0009] Such as figure 1 As shown, a maleic anhydride reaction cooling device of the present invention includes a housing 1, a plurality of cooling rods 2 inserted into the housing 1 from above, and partitions are arranged between adjacent cooling rods 2 . The baffles include lower baffles 3 with gaps in the upper parts and upper baffles 4 with gaps in the lower parts; the upper baffles and the lower baffles are arranged alternately.

[0010] In the embodiment, there are 6 cooling rods plugged into the housing, which are filled with cooling liquid, and 5 fast partitions are arranged between the 6 cooling rods. According to the distribution, one time is the lower partition, the upper partition, the lower partition, The upper partition and the lower partition evenly distribute the space to ensure the condensation effect.

[0011] The above is only a preferred embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com