Laser-tracker-based omnibearing measure method for space precision of machine tool

A technology of laser tracker and measurement method, which is applied to measurement devices, instruments, optical devices, etc., can solve problems affecting the accuracy of machine tools, and achieve the effect of accurate, faster, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

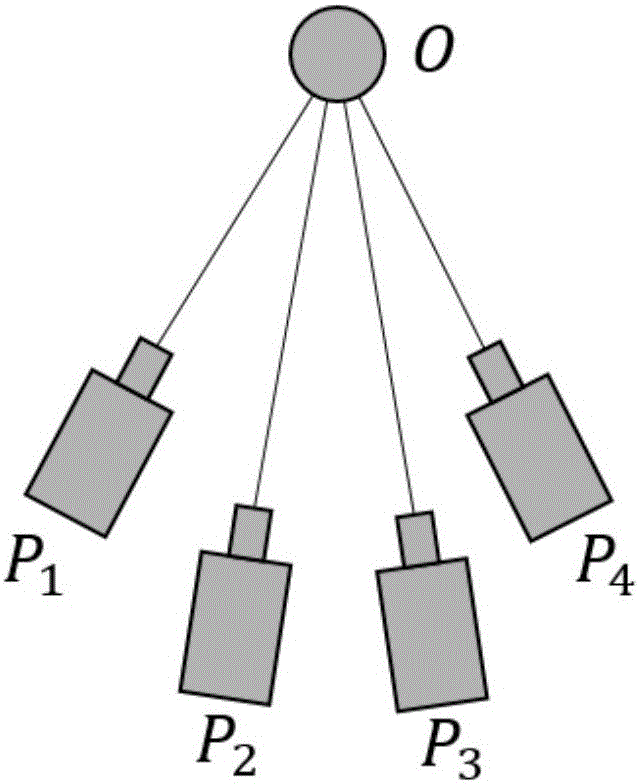

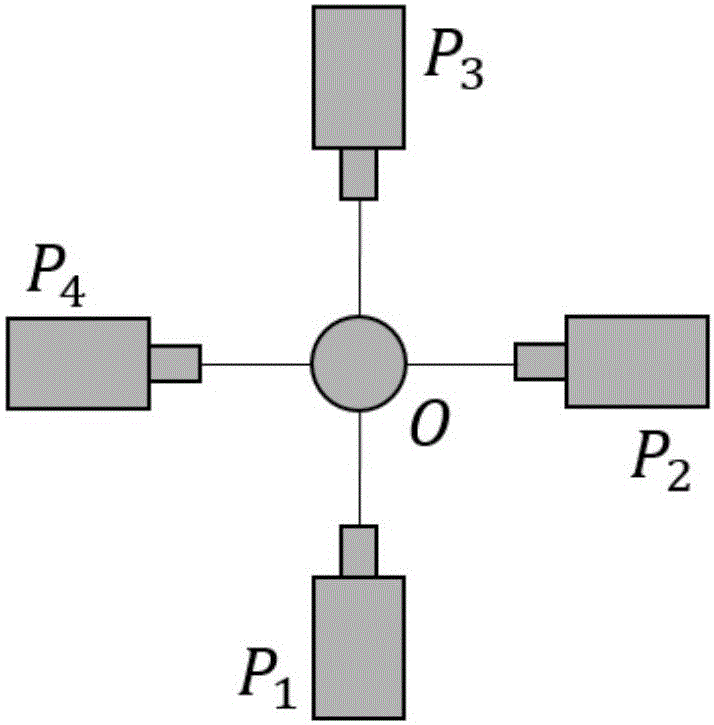

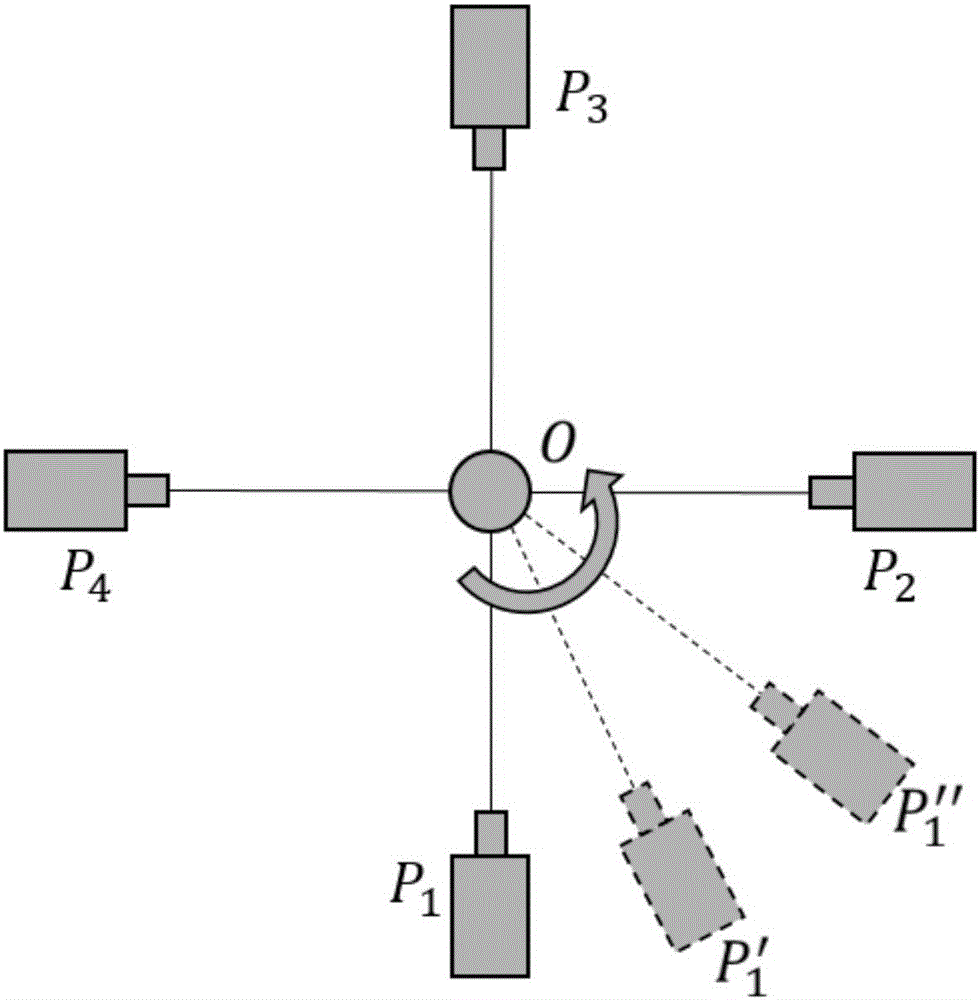

[0036] Referring to Figure 1, the base station is the position of the laser tracker when the laser tracking measurement system is used for measurement. To complete a measurement, it usually requires multiple laser trackers to measure at different base stations at the same time or a single laser tracker to measure at different base stations in time. , both of these two methods use the GPS measurement principle, and only use the distance measurement information of the laser tracker, which has high measurement accuracy; the latter "multi-base station time-sharing measurement" only needs one laser tracker, which greatly reduces the measurement cost .

[0037]The most commonly used laser tracking target mirror is to design a hollow corner cube prism in the center of a stainless steel ball to reflect the beam back to the laser source in parallel. The tracking system will follow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com