Preparation of cocr/ti extreme ultraviolet multilayer artificial crystal monochromator by nitrogen reactive sputtering and its manufacturing method

A technology of artificial crystals and manufacturing methods, which is applied in the direction of using multiple reflections to generate spectra and spectrum generation, and can solve problems such as poor film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

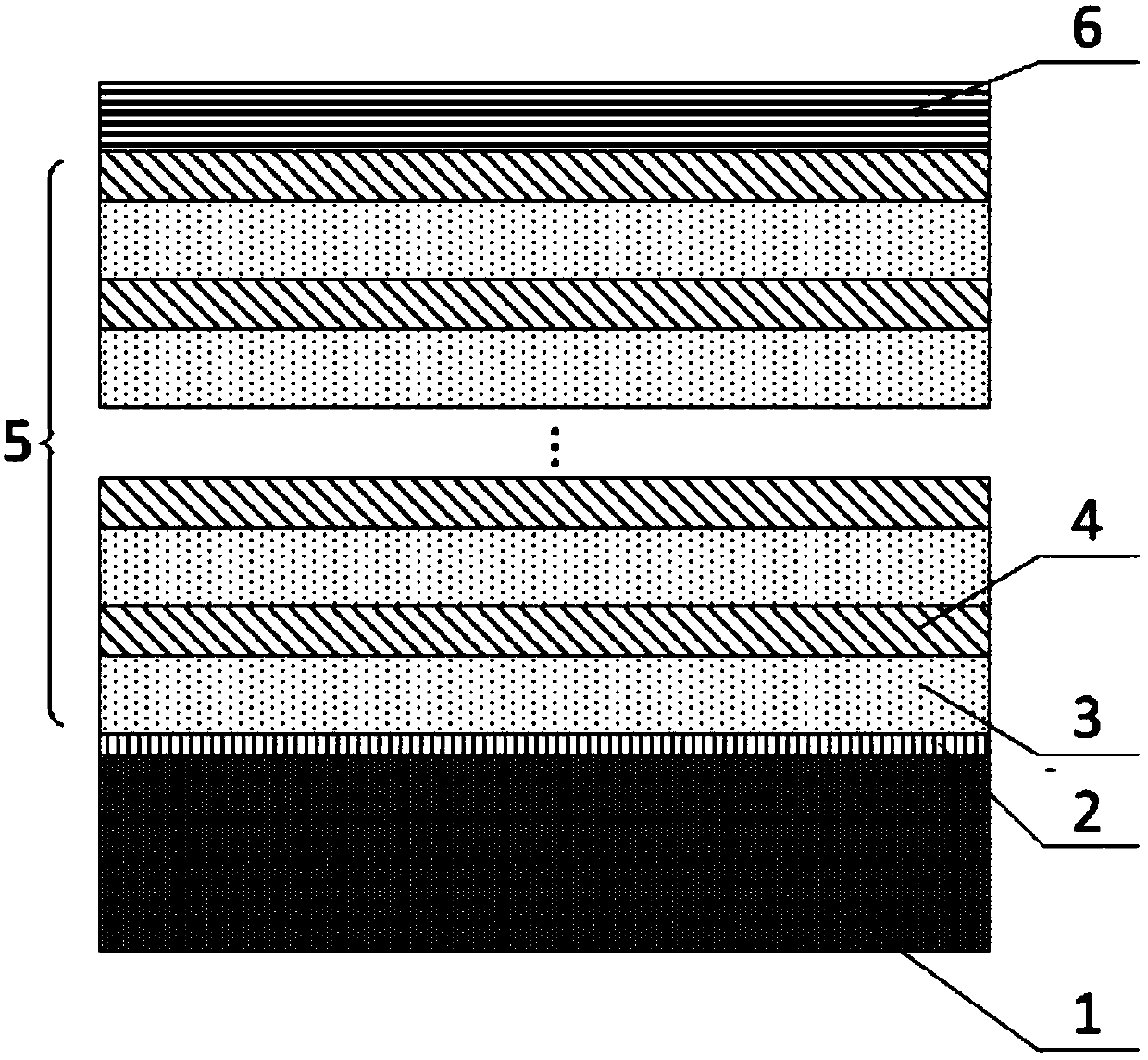

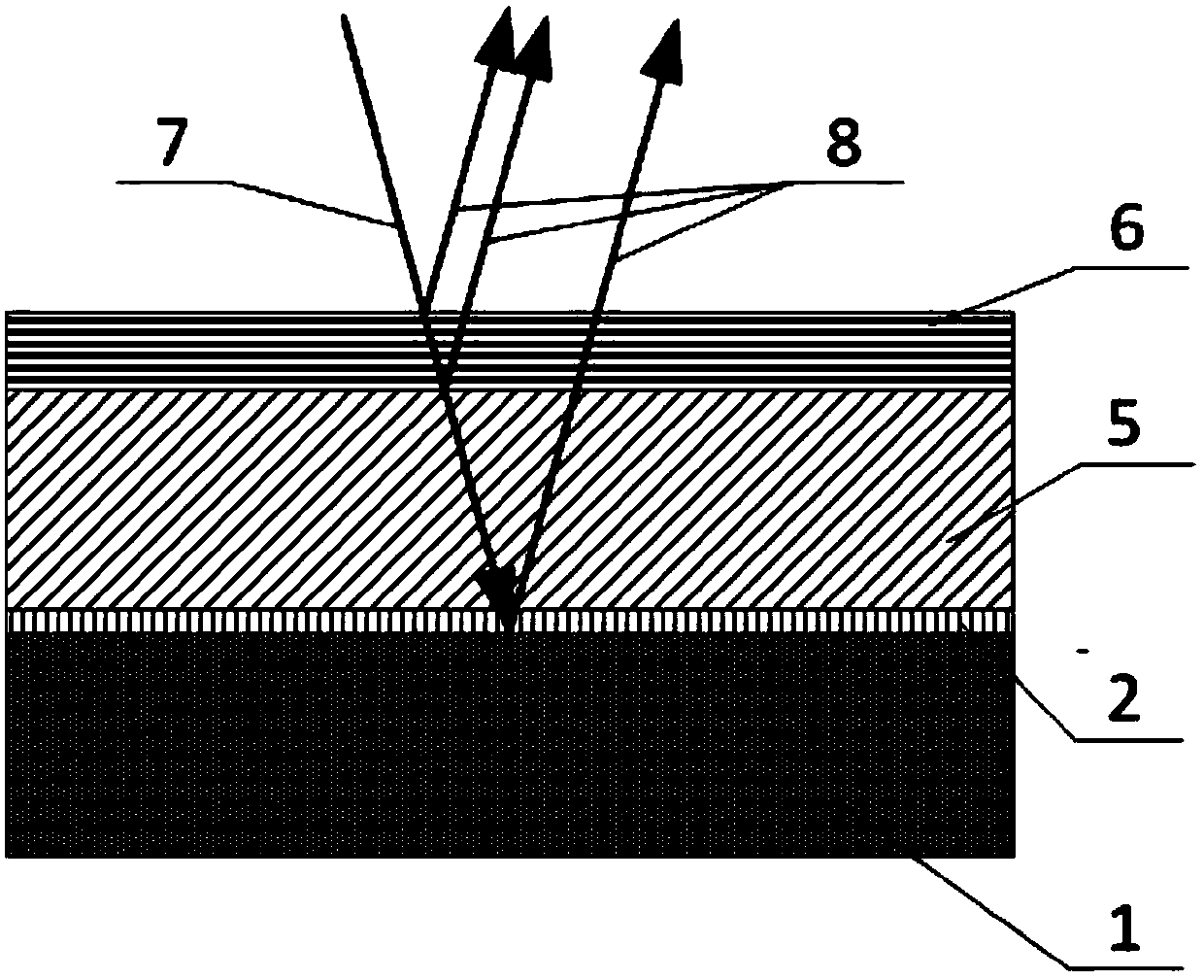

[0023] The manufacture method of CoCr / Ti extreme ultraviolet multilayer film artificial crystal monochromator, such as figure 1 As shown, firstly, a monocrystalline silicon wafer (with a crystal orientation of (100)) or glass is selected as the substrate 1 of the monochromator, and the roughness of the substrate is 0.2-0.5 nanometers. Then a Cr film layer with a thickness of 5-10 nanometers is plated on the substrate as the primer layer 2 . CoCr film layer 3 and Ti film layer 4 are alternately plated on the primer layer 2 to form CoCr / Ti periodic multilayer film artificial crystal 5, the number of cycles is 50-100, and the ratio of the thickness of CoCr to the thickness of Ti is 1:1 , the first layer plated in the periodic multilayer artificial lens 5 is a CoCr layer with a thickness of about 1-5 nm, and the last layer is a Ti layer with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com