Correction method of influence of pore diameter on evaluating stress of metal materials through critical refraction longitudinal waves

A critical refraction, metal material technology, applied in the direction of measuring force, force/torque/work meter, measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

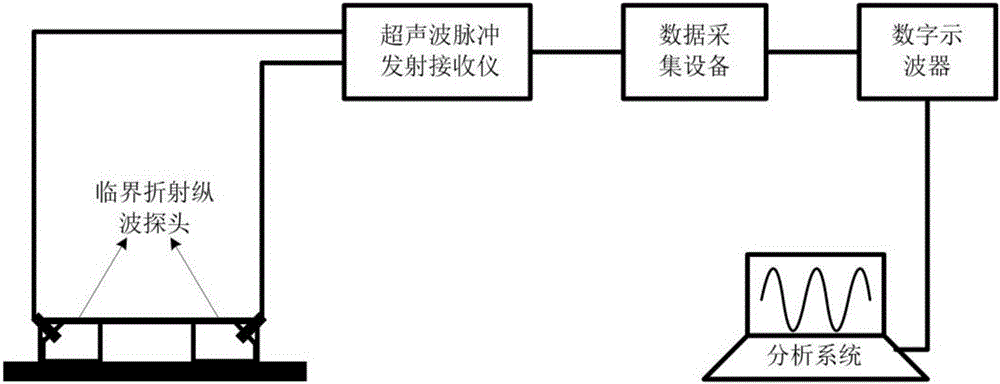

[0036] figure 1 It is a schematic diagram of the connection relationship of the critical refraction longitudinal wave evaluation stress system of the present invention, referring to figure 1 As shown, the ultrasonic pulse transmitter receiver, data acquisition equipment, digital oscilloscope, and analysis system are connected in sequence.

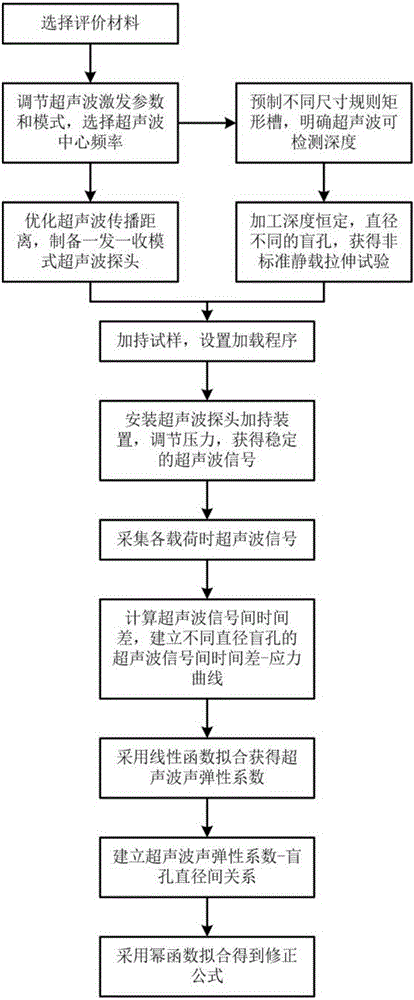

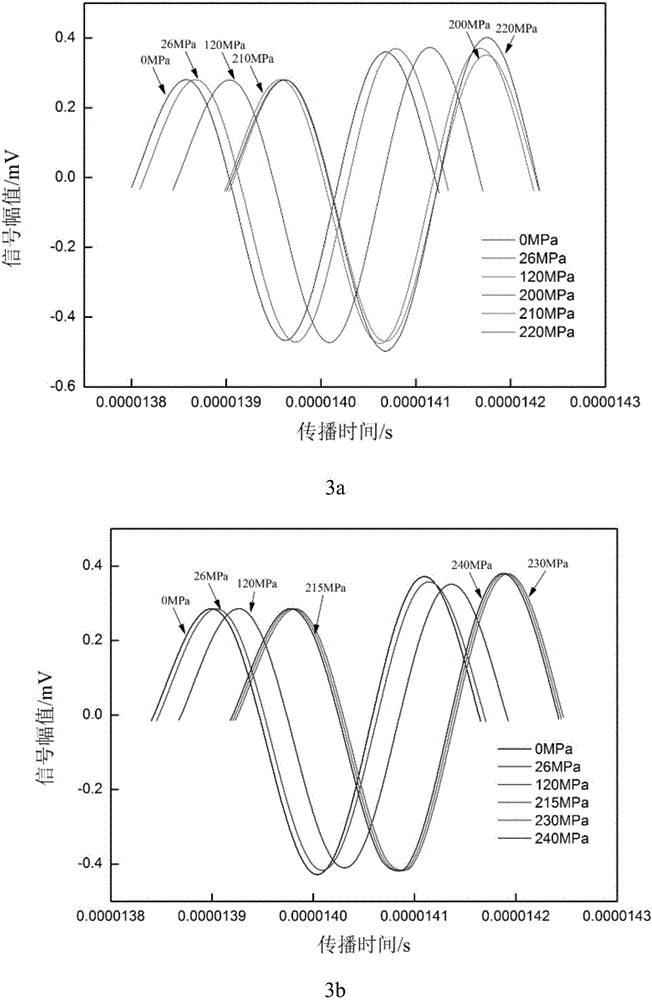

[0037] Taking Q235 steel in the hot-rolled state as an example, the correction method for evaluating the stress of metal materials affected by the critical refraction longitudinal wave by the pore diameter is described. The correction formula (the function between the critical refraction longitudinal wave acoustoelastic coefficient and the diameter of the blind hole) is obtained as follows:

[0038] Step 1. Taking the hot-rolled Q235 steel with a thickness of 6.0mm as the research object, adjust the excitation parameters of the ultrasonic pulse transmitter and receiver 5072PR, select the single-probe excitation mode, and use the edge reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com