Apparatus and method for detecting less installed screw on engine cylinder cover

An engine cylinder head and detection device technology, which is applied in the direction of optical device exploration, etc., can solve the problems such as the inability to apply to the mixed-flow production line of special-shaped products and small batch production lines, the limitation of the actual application scope of the robot, the failure of the robot to perform tasks, etc. Low cost, complete detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

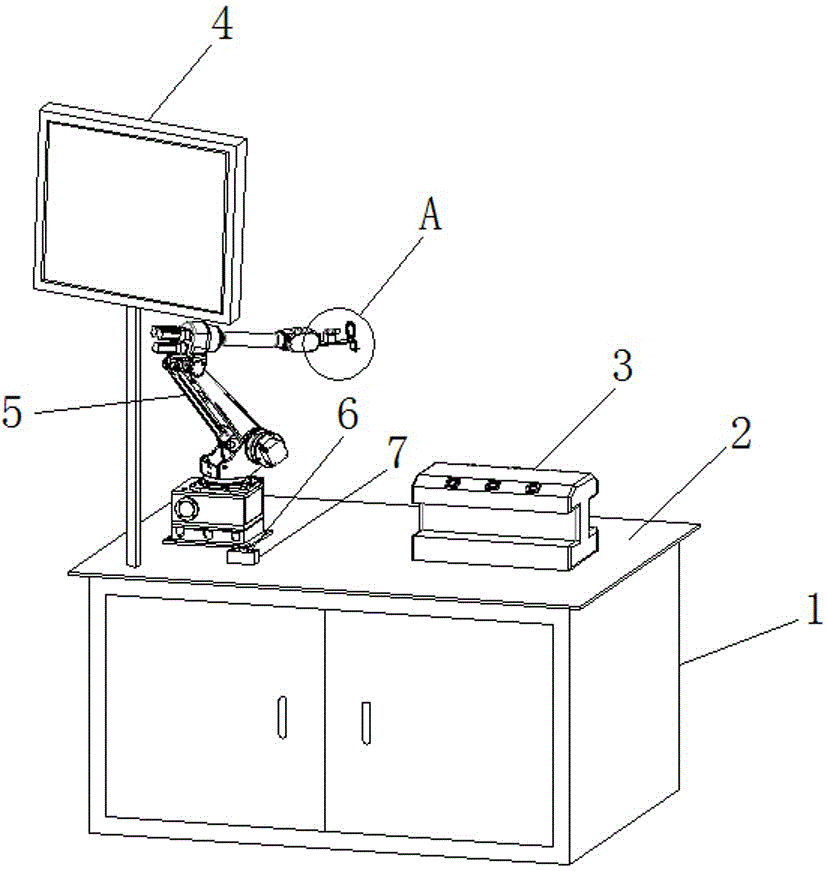

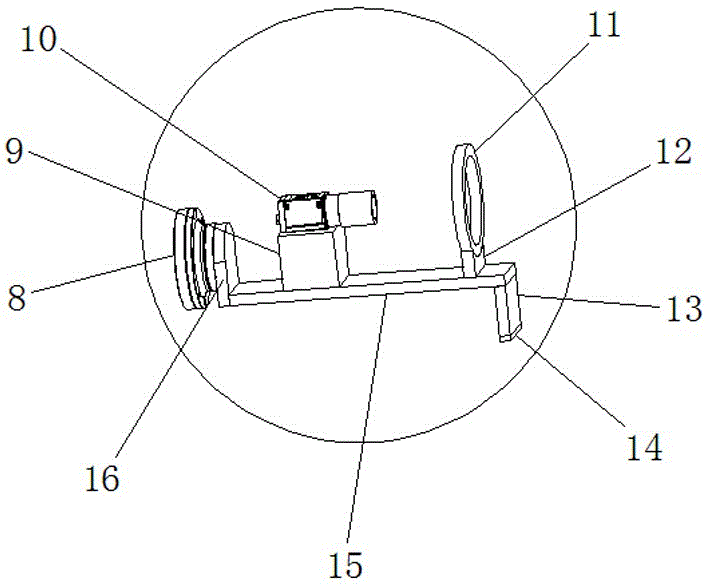

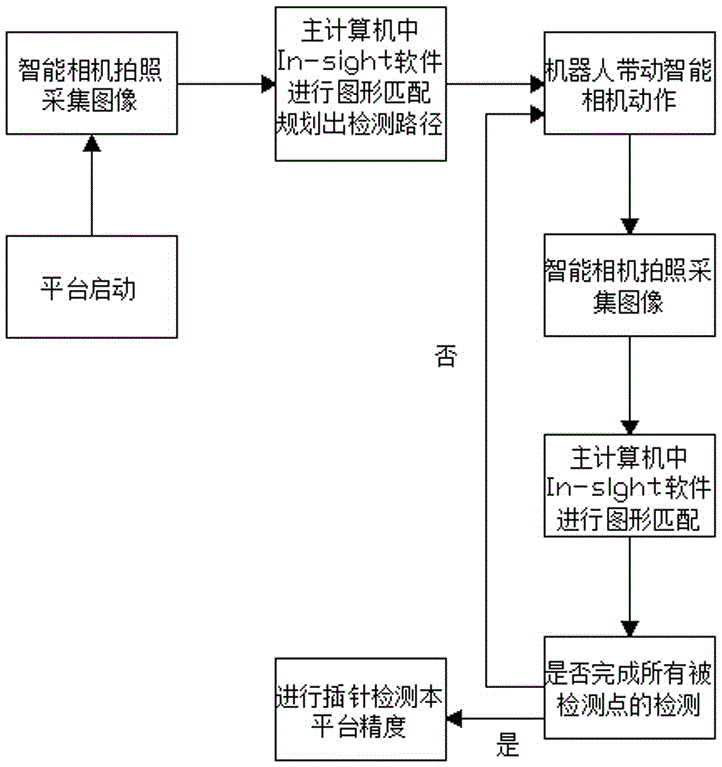

[0029] Such as figure 1 and figure 2Shown, a kind of engine cylinder head 3 screws missing detection device, comprise control cabinet 1, the top of described control cabinet 1 is work platform 2, and the top of the front side corner of described work platform 2 is provided with host computer 4, described The main computer 4 is connected to the control cabinet 1, and the side of the working platform 2 provided with the main computer 4 is provided with a light six-axis robot 5, and the rotating manipulator 8 at the end of the light six-axis robot 5 is provided with a camera unit and a platform Accuracy detection unit, the light six-axis robot 5 and the camera unit are respectively connected to the main computer 4, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com