Optical synthesizer tuning using fine and coarse optical frequency combs

A technology of optical frequency combs and synthesizers, which is used in optical demodulation, optics, lasers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

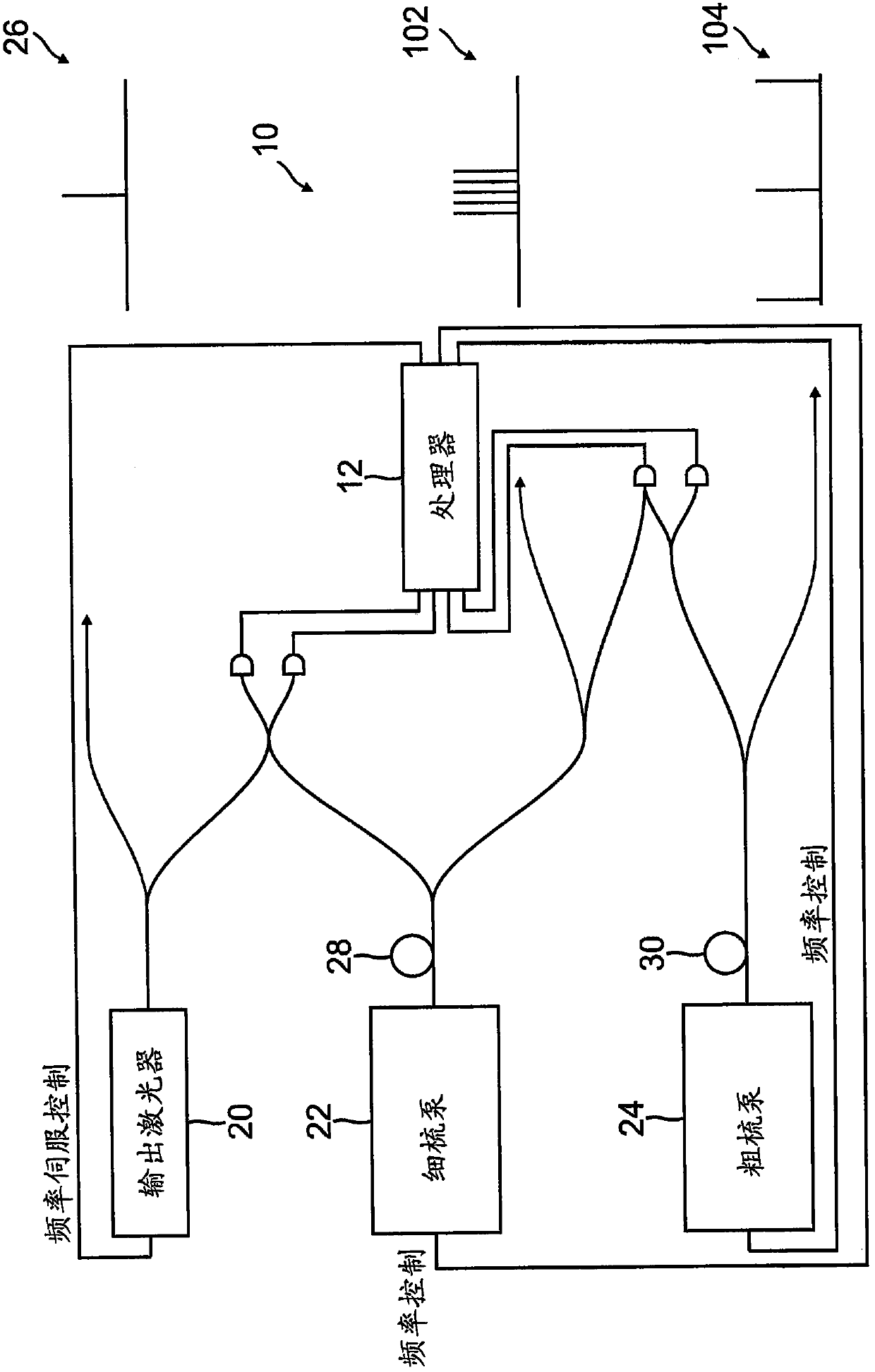

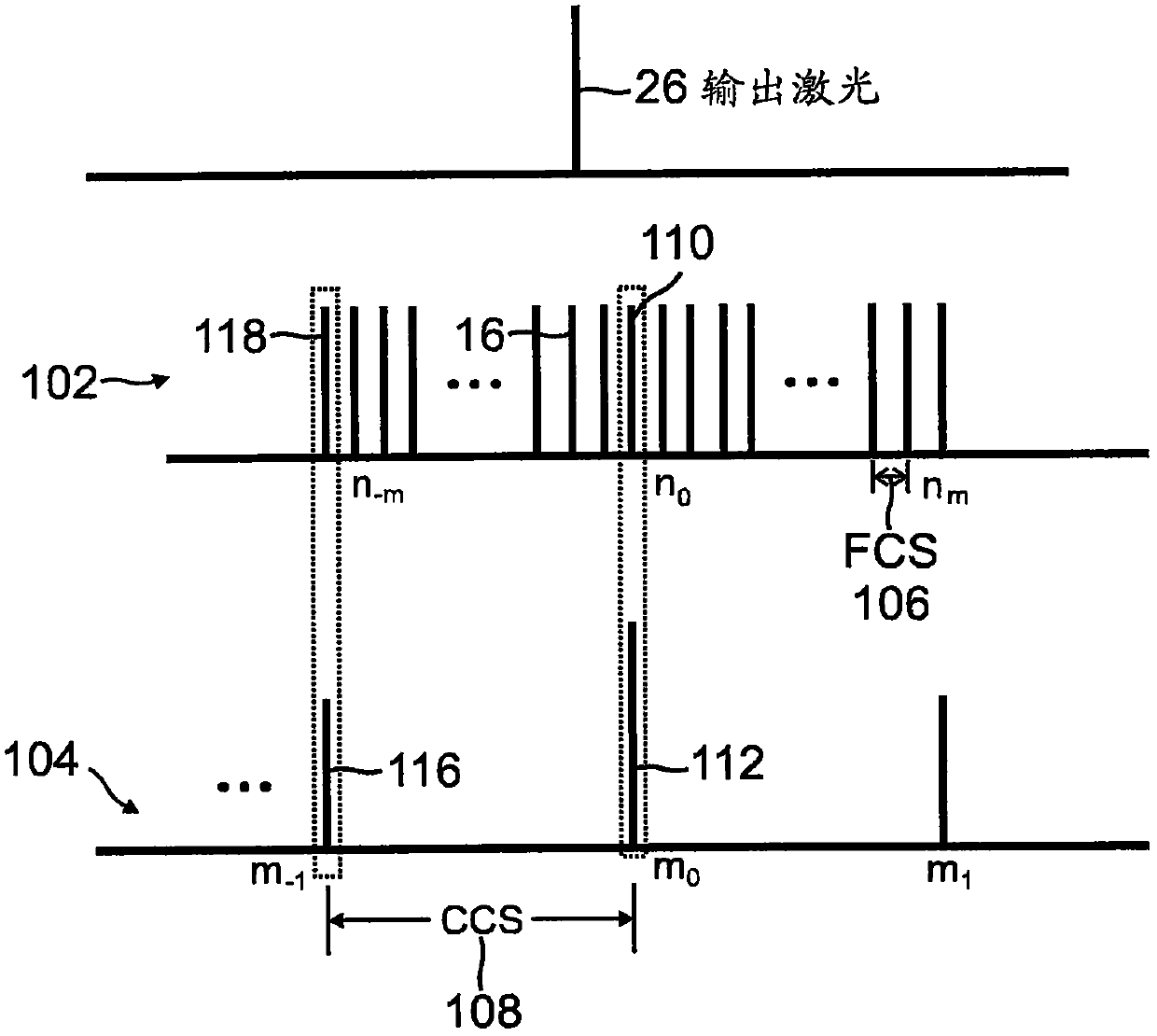

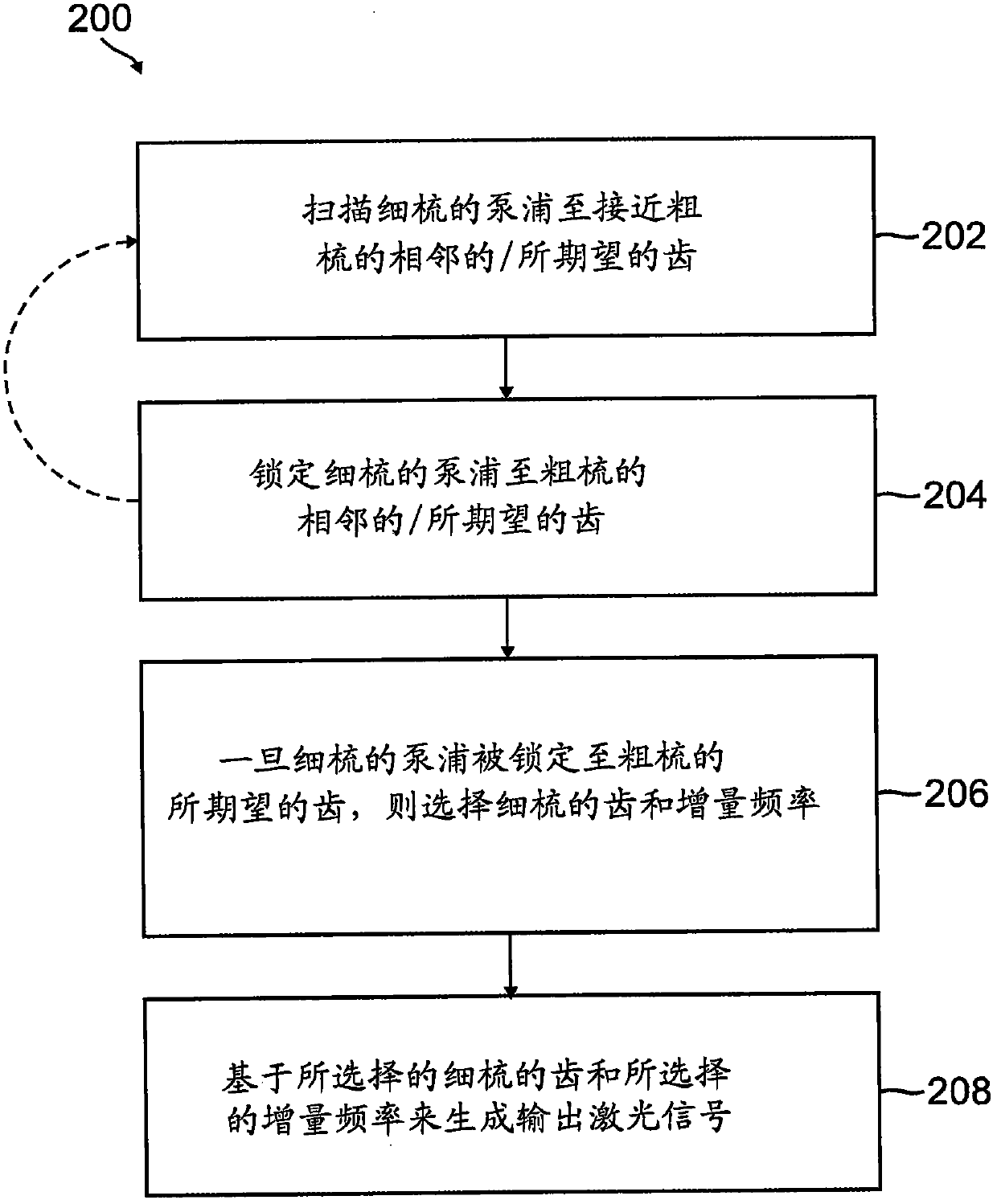

[0052] Example 1 includes an optical frequency synthesizer comprising: a coarse optical frequency comb pumped with a first pump laser, wherein the absolute frequency of at least one tooth of the coarse optical frequency comb is set; a fine optical frequency comb with a frequency spacing between the teeth a frequency comb locked to a fractional or integer multiple of a radio frequency reference, the fine optical frequency comb being pumped with a second pump laser, wherein the second pump laser is initially locked to the first tooth of the coarse optical frequency comb; and output laser; wherein the optical frequency synthesizer is configured to: scan the second pump laser to a desired tooth close to the coarse optical frequency comb; lock the second pump laser to the desired tooth; and lock the second pump laser to the desired tooth; The desired tooth is then based on the tooth of the fine optical frequency comb with an output laser to generate an output signal.

example 2

[0053] Example 2 includes the optical frequency synthesizer of Example 1, wherein the optical frequency synthesizer is configured to repeat the scanning and locking of the second pump laser for each tooth between the first tooth and the desired tooth such that the second The pump laser is incrementally stepped from the first tooth to the desired tooth.

example 3

[0054] Example 3 includes the optical frequency synthesizer of Example 1, wherein scanning the second pump laser includes scanning the second pump laser from the first tooth, and while scanning the second pump laser, the coarse Any teeth of the optical frequency comb are counted and based on the number of teeth that have been passed during the scan it is determined that the second pump laser is close to the desired tooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com