Control circuit of electric tool

A technology for controlling circuits and power tools, which is used in motor control, electrical program control, DC motor speed/torque control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the invention will be further described in detail below in conjunction with the accompanying drawings.

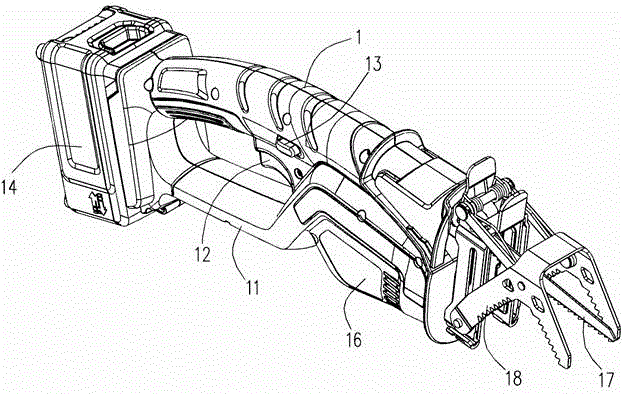

[0020] The present invention uses a reciprocating saw as the electric tool in the embodiment to illustrate the technical solution, but the technical solution of the present invention is not only used for the reciprocating saw, but also can be applied to other electric tools, such as pruners, hand-held pruners, etc. figure 1 The shown reciprocating saw includes a main body 1, on which is formed a handle part 11 that can be held by the operator, and a trigger switch 12 and a safety lock 13 are arranged at the lower part of the handle part, and the user presses the trigger switch 12 and the safety lock 13 at the same time when using to start. A battery pack 14 is arranged at the tail of the reciprocating saw, and the battery pack 14 can be separated from the tail of the reciprocating saw. A drive motor 16 is set at the front of the reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com