Commutator, rotor and motor

一种换向器、电机轴的技术,应用在制造电动发电机、电路、集电器等方向,能够解决电机重量加重、吸收效果欠佳、结构复杂等问题,达到减轻重量、结构和制造工艺简化、大电容的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

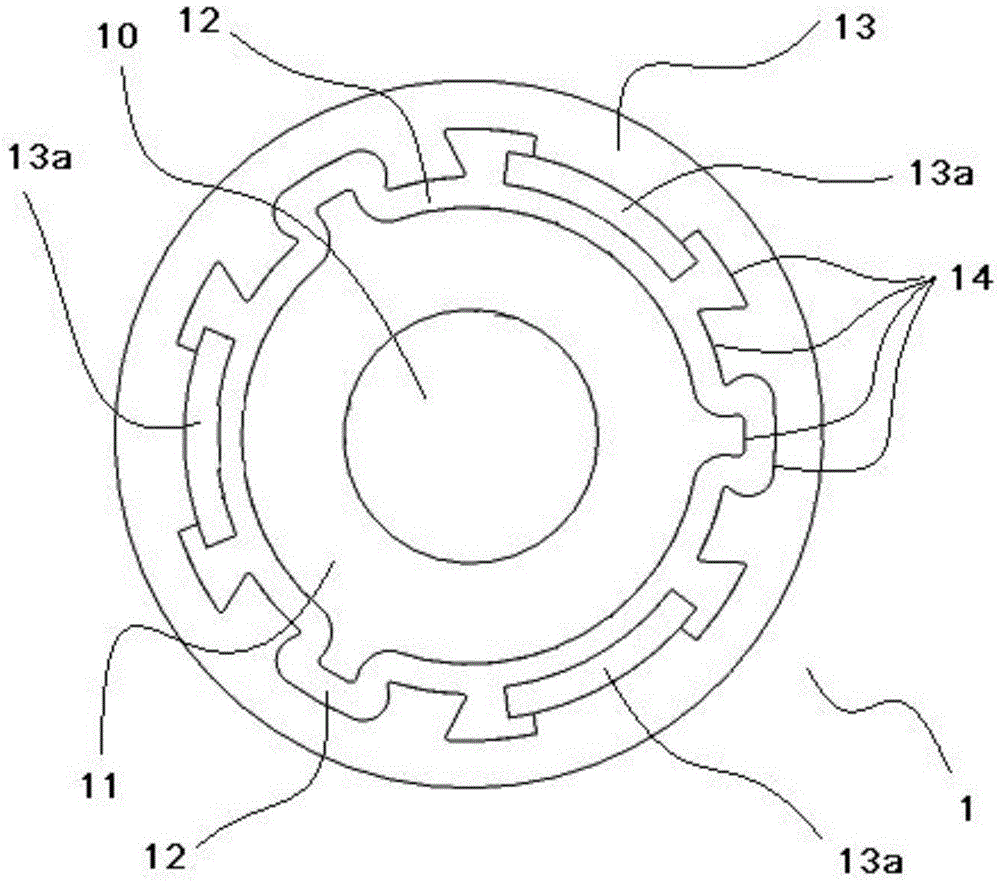

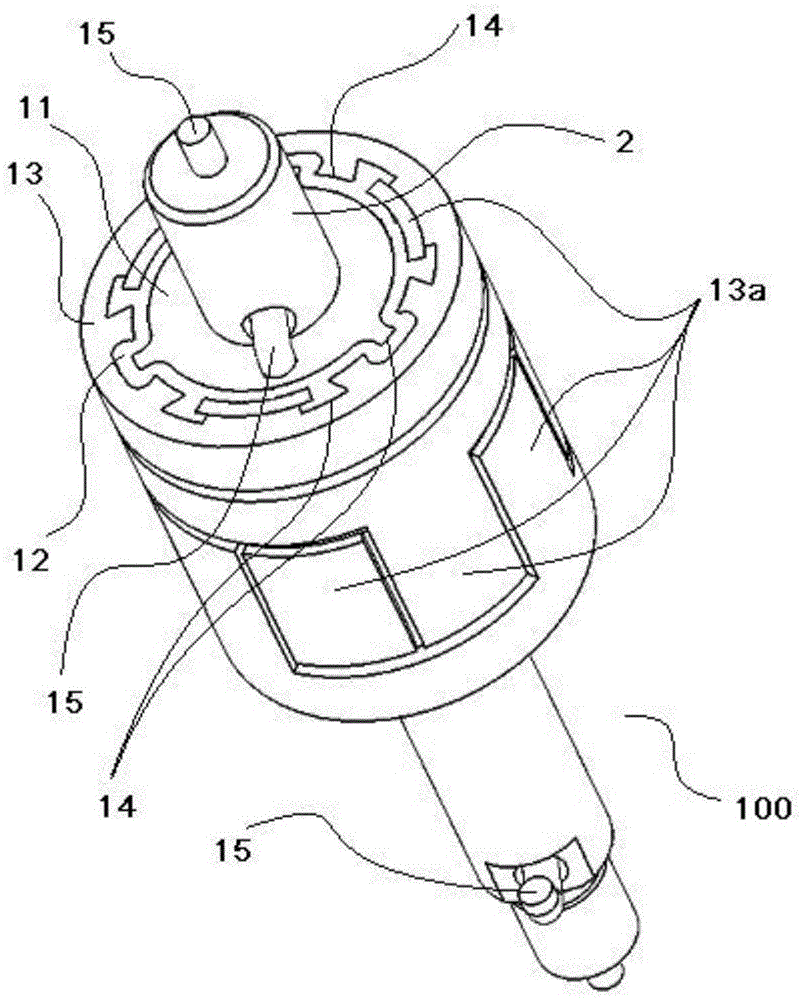

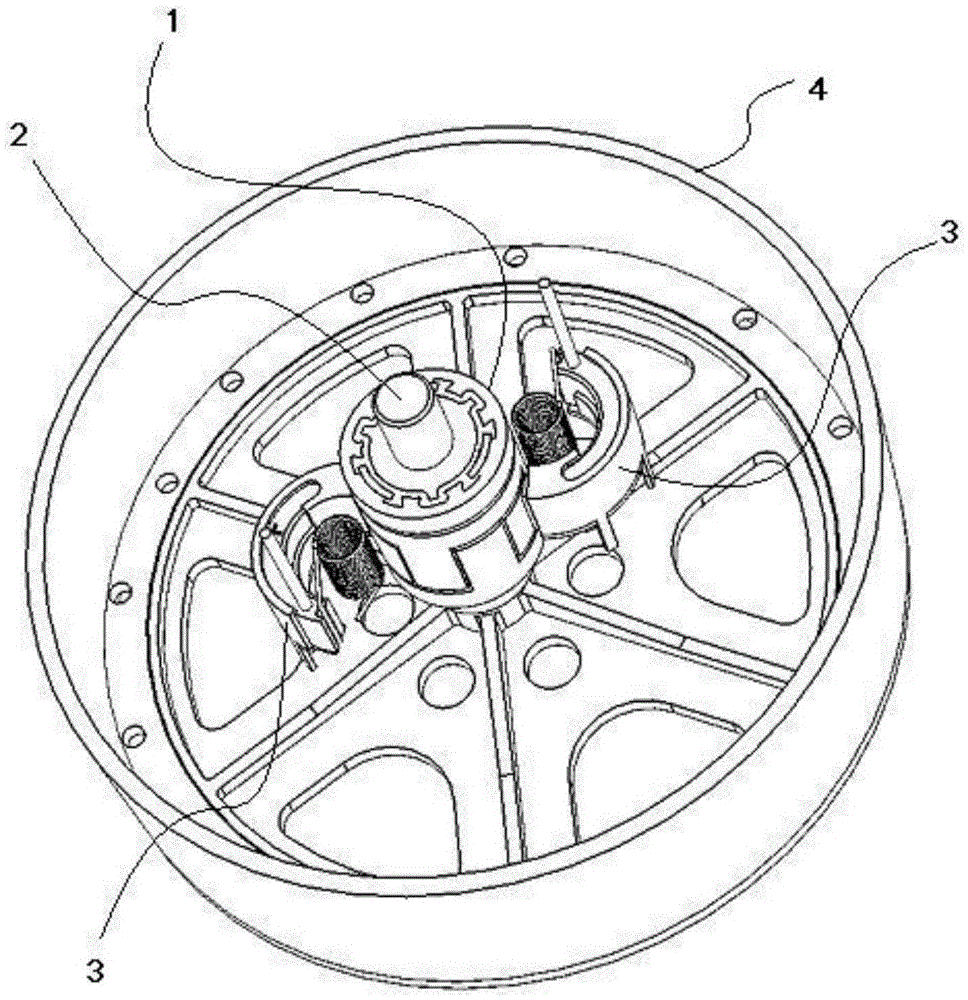

[0033] As an embodiment of the commutator of the present invention, such as figure 1 As shown, the commutator 1 of this embodiment includes a conductor layer 11 in the inner ring, an insulating layer 12 surrounding the conductor layer 11 in the radial direction, and a commutator segment layer 13 surrounding the insulating layer in the radial direction. Preferably, the conductor layer 11 is cylindrical, and the motor shaft installation hole 10 is provided in the center of the conductor layer 11 , and the conductor layer 11 and the commutator layer 13 are insulated from each other by the insulating layer 12 . The commutation segment layer 13 includes a plurality of commutation segments 13a. The commutator layer 13 can be made of copper, the insulating layer 12 can be made of resin, and the conductor layer 11 can be made of copper, aluminum or other metal materials. The commutator 1 is installed on the motor shaft of the motor through the rotating shaft installation hole 10 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap