Bearing support for maintenance of power transmission line

A technology for transmission lines and support frames, which is applied to overhead lines/cable equipment, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of reducing potential safety hazards, low cost, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

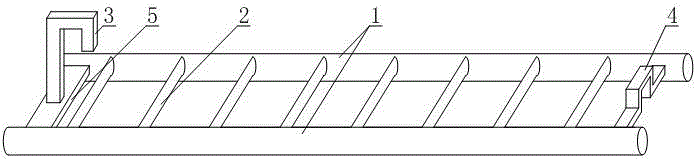

[0014] Such as figure 1 As shown, a support frame for transmission line maintenance includes a horizontal positioning rod 1, a longitudinal support rod 2, a hook 3, a connecting plate 4 and a rectangular positioning plate 5, wherein the number of the horizontal positioning rods 1 is two, and the two horizontal positioning rods The positioning rods 1 are arranged horizontally and vertically at a certain interval. In this embodiment, the distance between the two horizontal positioning rods 1 is 50-80 cm. The longitudinal support bar 2 is longitudinally and horizontally arranged, and the front and rear ends of the longitudinal support bar 2 are respectively connected with two transverse positioning bars 1 . In this embodiment, there are multiple longitudinal support rods 2, and the multiple longitudinal support rods 2 are arranged at equal intervals in the transverse direction. In the specific setting of this embodiment, the distance between any two adjacent longitudinal support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com