Welding robot for machining of pressure container

A technology for welding robots and pressure vessels, applied in household containers, metal processing, welding equipment, etc., can solve the problems of increased welding difficulty and labor intensity, reduced welding quality, hidden safety hazards, etc., to achieve simple and efficient welding work and improve welding efficiency. , to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

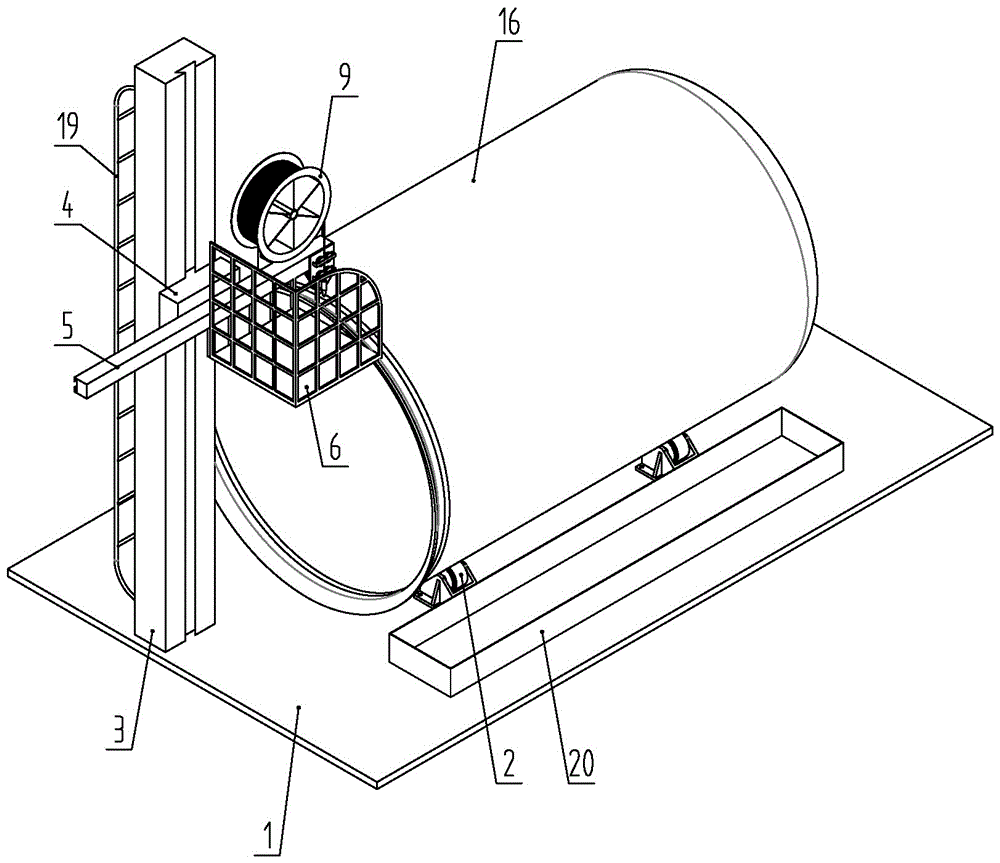

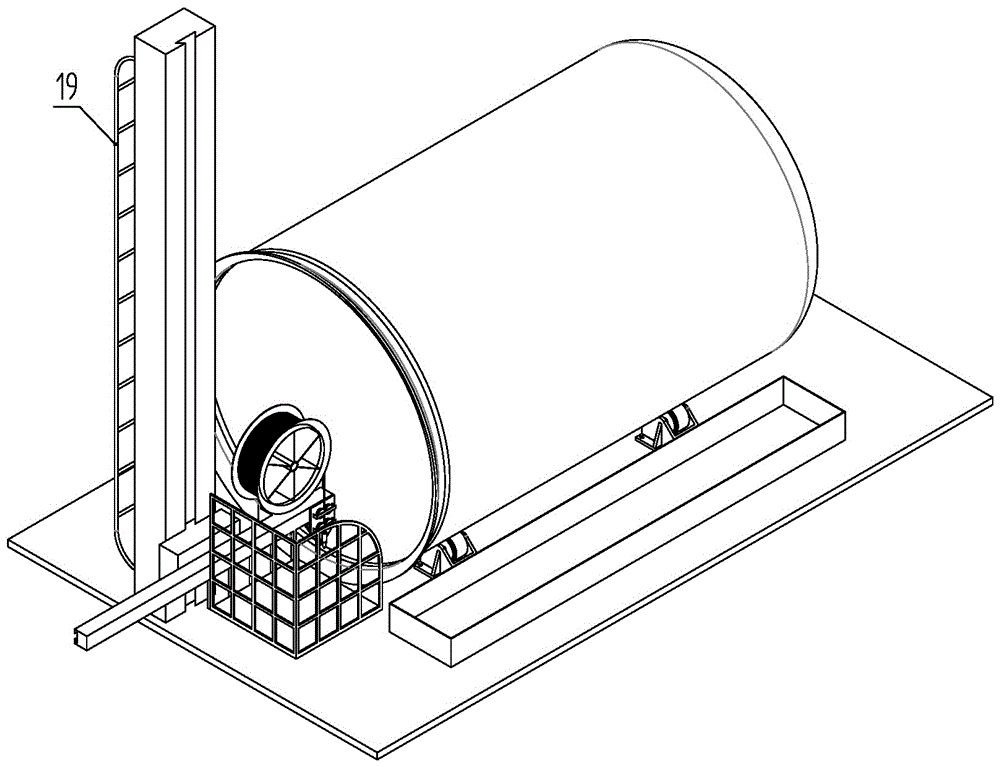

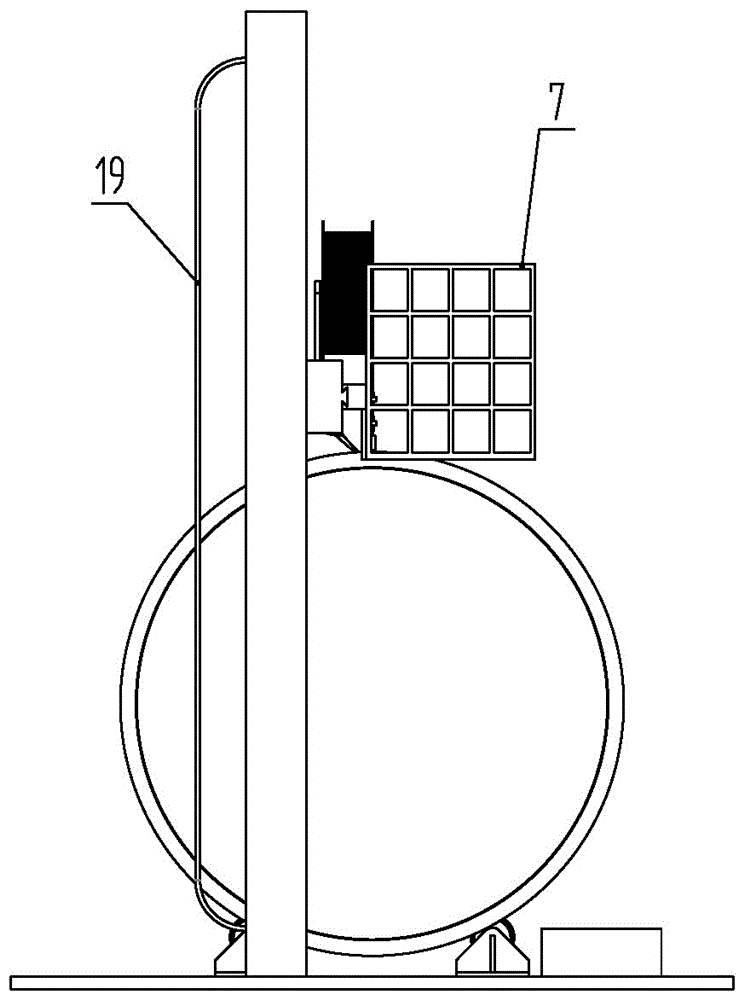

[0024] Such as Figures 3 to 8 As shown, taking a 2000L storage tank as an example, the welding robot for welding the storage tank is described in detail, which includes a base 1, a supporting roller 2, a driving motor, a traveling device, a welding device, and an electrical control device for controlling the movement of each component.

[0025] Specifically, there are two pairs of support rollers 2, which support the storage tank 16 together, and drive the storage tank 16 to rotate through a drive motor connected to one of the support rollers 2 .

[0026] The running device includes a column 3, a lifting platform 4, and a cantilever 5. Lifting platform 4 is slidably assembled on column 3, can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com