Continuous batching device of immersed tube method tunnel sand foundation and batching method thereof

An immersed tube method and tunnel technology, which are applied in batching and batching instruments, raw material supply devices for sales, clay preparation devices, etc., can solve the problems of limited working surface, huge impact on the quality of professional-quality sand filling material configuration, and low work efficiency, so as to improve the The effect of labor efficiency, improving configuration quality and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention can be specifically implemented through the disclosed technology, and the present invention can be further described through the following examples, however, the scope of the present invention is not limited to the following examples.

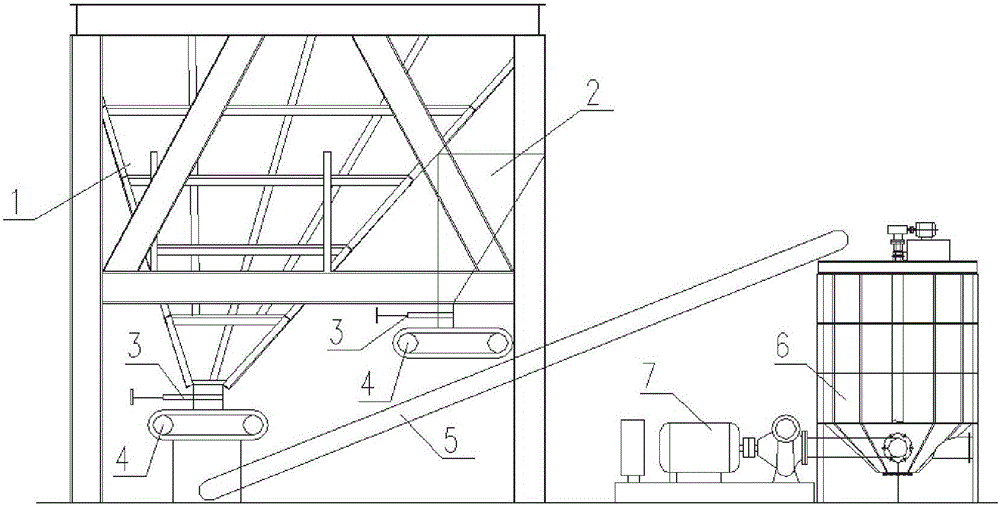

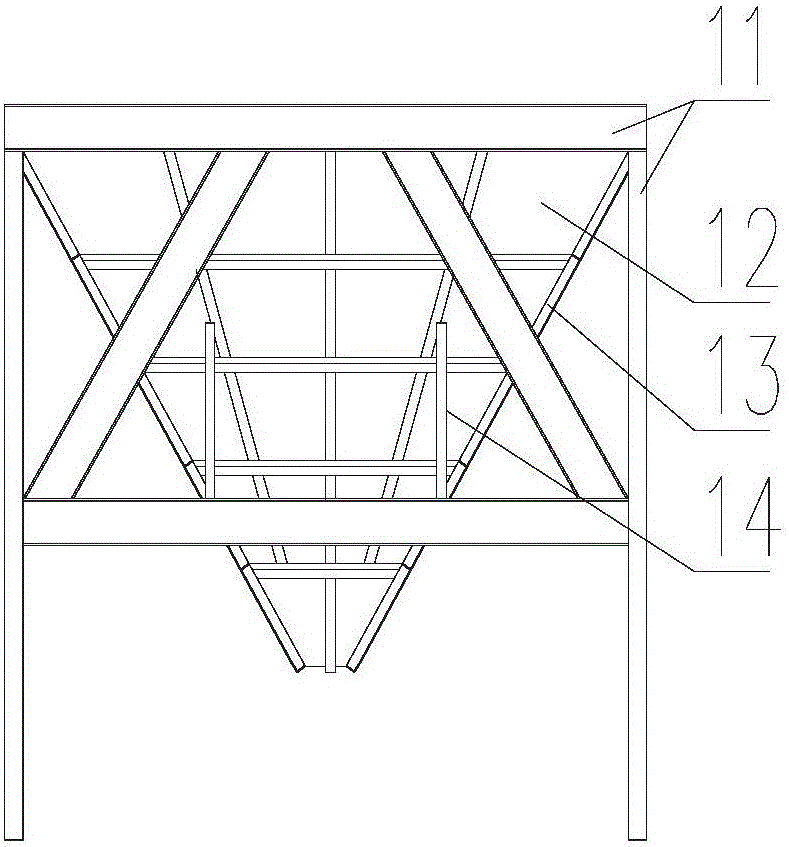

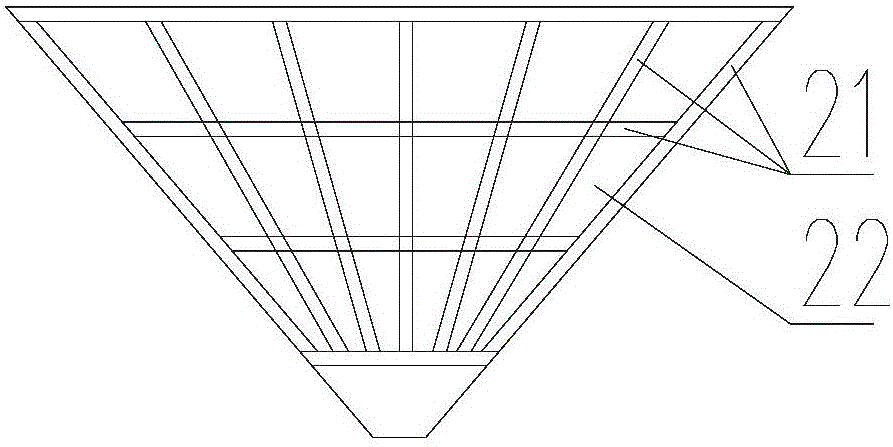

[0031] Example figure 1 Shown: a continuous batching device for tunnel sand foundation with immersed tube method, including sand funnel 1, cement clinker funnel 2, control bucket door 3, conveyor chain belt machine 4, mixture conveyor belt conveyor 5, mixing bucket 6, and water pump 7 .

[0032] The present invention builds a frame of steel structure first on the barge platform, then will install sand funnel 1 and cement clinker funnel 2 on the frame of steel structure in sequence; Then, under sand funnel 1 and cement clinker funnel 2 respectively Install a control hopper door 3, the control hopper door 3 is used for the flow rate of the sand in the sand funnel 1 and the flow of cement in the cement clinker hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com