Equipment for detecting braking performance of additional brake

A technology for testing equipment and brakes, which is applied in escalators, transportation and packaging, etc. It can solve the problems of limited simulation height, heavy workload, and troublesome testing, so as to avoid damage to the host, reduce workload, and occupy a small area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

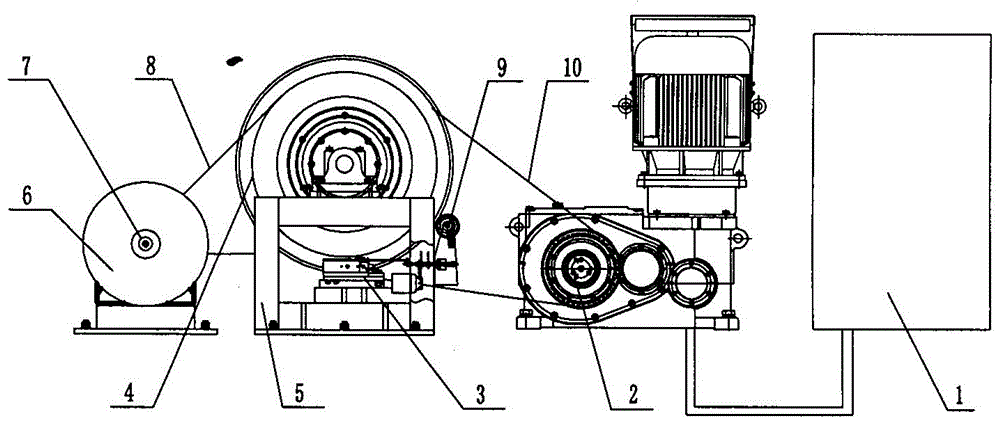

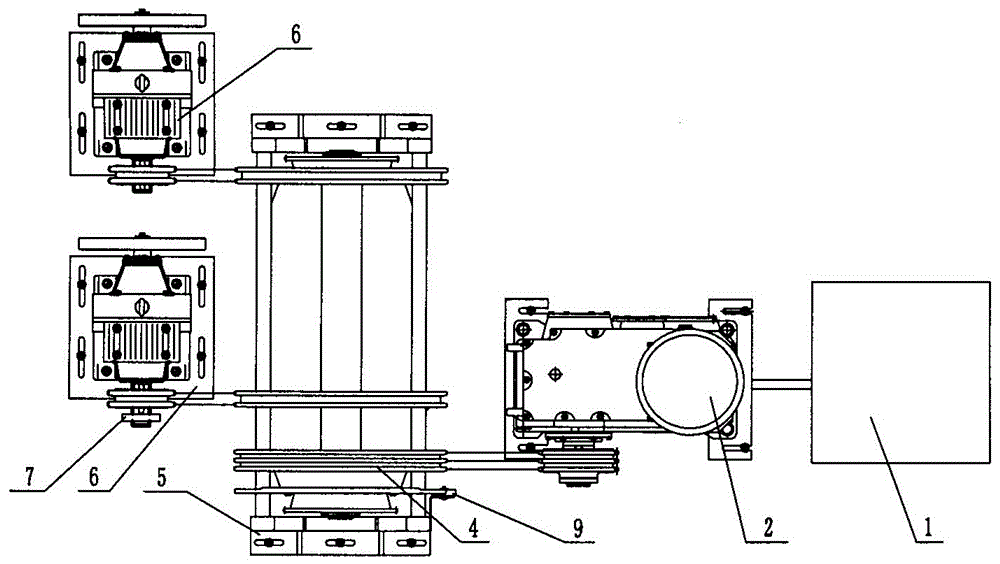

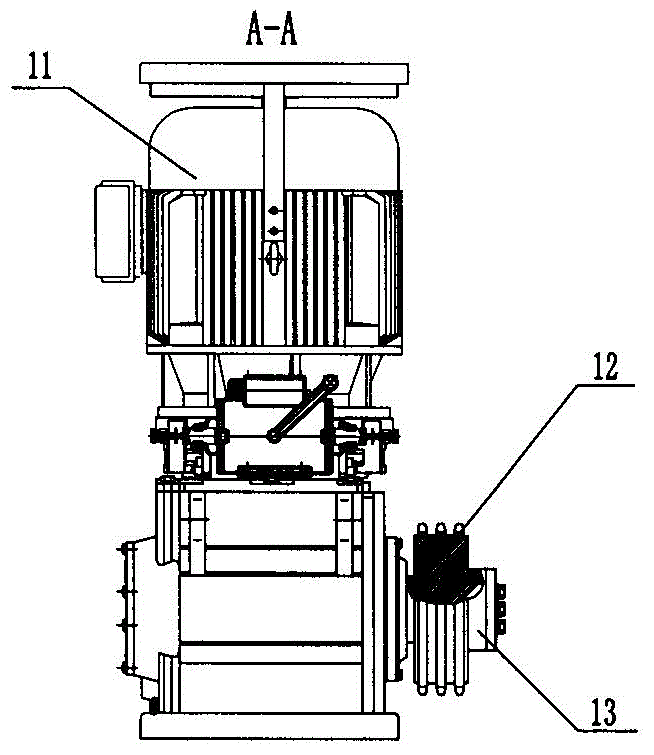

[0020] according to Figure 1~6 The specific structure of the present invention will be described in detail. The testing equipment for the braking performance of the additional brake includes a traction machine 2 controlled by a frequency converter 1. The traction machine 2 is driven by the large and small drive sprockets 16, 12 and is provided with a main drive 4 with an additional brake 3. The main drive 4 Components such as the energy conversion device 6 driven by the large and small transmission sprockets 17, 21 and the detection control circuit. The operating speed of the equipment is controlled by the frequency converter 1, and the frequency converter 1 changes the output frequency so that the main transmission shaft 18 of the traction machine 2 can obtain a certain speed, and the small drive sprocket 12 on the traction machine 2 is driven by the drive chain 10 to The speed is transmitted to the large drive sprocket 16 on the main drive 4, and the large drive sprocket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com