Yellow phosphorus furnace lid structure, manufacturing method of yellow phosphorus furnace lid structure and heat insulation material adopted in furnace lid structure

A technology of yellow phosphorus furnace and cover structure, which is applied in the direction of furnace, furnace components, lighting and heating equipment, etc. It can solve the problems of heavy stainless steel furnace cover, high production cost of yellow phosphorus, high cost of yellow phosphorus furnace cover, etc., and achieve beautiful appearance , to avoid the effect of instability and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

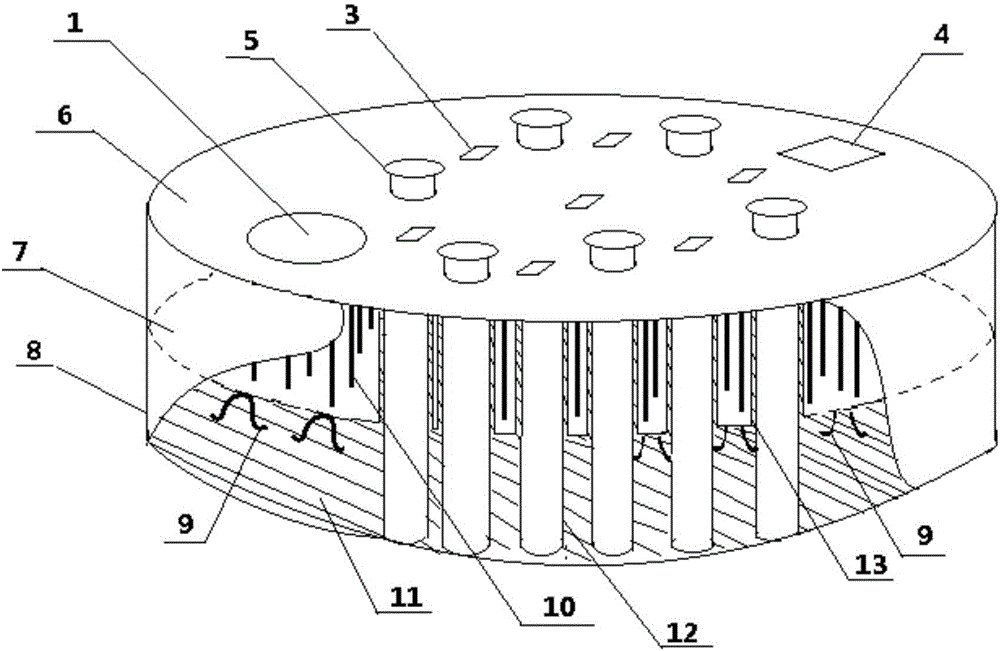

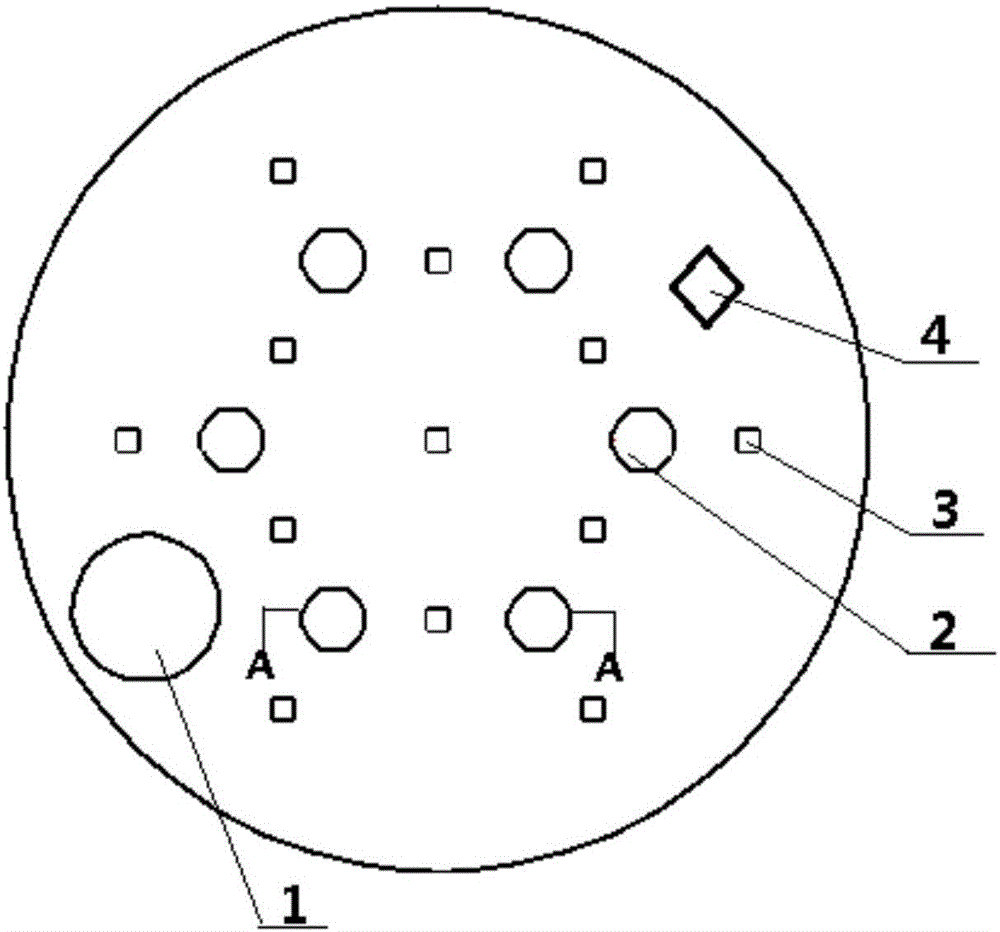

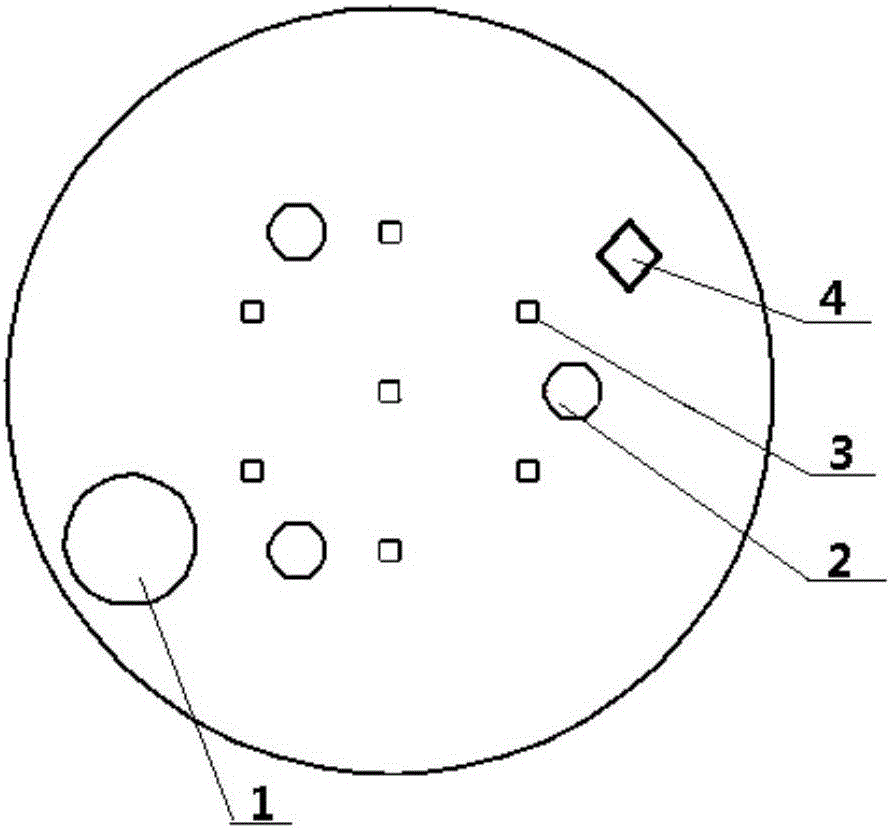

[0034] Such as figure 1 , 2 , shown in 3, 4, and 5: a kind of yellow phosphorus furnace cover structure, is made up of upper deck 6 and lower deck 7, ring plate 8, wherein upper deck 6 and lower deck 7 are connected by ring plate 8, and on upper deck A circular box is formed between 6 and the lower plate 7; electrode holes 2 and feeding holes 3 are arranged on the upper plate 6, and the electrode holes 2 and feeding holes 3 are alternately arranged on the upper plate 6, and on the upper plate 6 An inspection hole 1 and an air guide hole 4 are also provided, and the inspection hole 1 is arranged opposite to the position of the air guide hole 4; and electrode holes, charging holes, inspection holes and Air guide hole; And the electrode hole 2, feed hole 3, inspection hole 1, air guide hole 4 corresponding to the lower floor plate 7 on the electrode hole 2, the feeding hole 3, the inspection hole 1, the air guide hole 4 on the upper plate 6 pass through the first The dividing p...

Embodiment 2

[0040] Such as figure 1 , 2 , 3, 4, and 5 show: the preparation method of the yellow phosphorus furnace cover structure, comprising the following steps:

[0041] 1) Select the steel plate, and cut the steel plate into two circular steel plates according to the size of the mouth of the yellow phosphorus furnace, and cut the electrode hole 2, the feeding hole 3, the air guide hole 4 and the inspection on the two circular steel plates respectively. Hole 1, during the cutting process, two circular steel plates are overlapped and cut together, and cut through at one time, and then select one of them as the upper plate 6 and the other as the lower plate 7;

[0042] 2) Weld the magnetic isolation and power saving component 5 on the electrode hole 2 on the upper plate 6, and ensure that the magnetic isolation and power saving component 5 is concentric with the electrode hole 2; Weld the inner rib plate 10, and weld the first separator 12 and the second separator 13 on the correspond...

Embodiment 3

[0047] On the basis of embodiment 2, other are all the same as embodiment 2, and described step, it also comprises welding pouring reinforcement on the lower floor plate in the thermal insulation tank before step 5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com