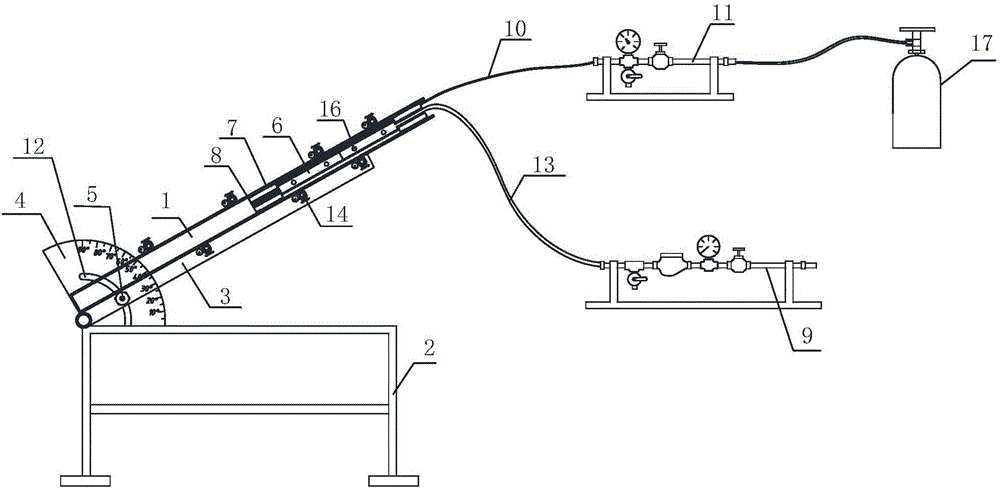

Floor rock mass permeability coefficient test simulation method

A technology of permeability coefficient and simulation method, which is applied in the field of test and simulation of floor rock mass permeability coefficient, and can solve the problems that numerical simulation cannot reflect the site conditions well and the workload is heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

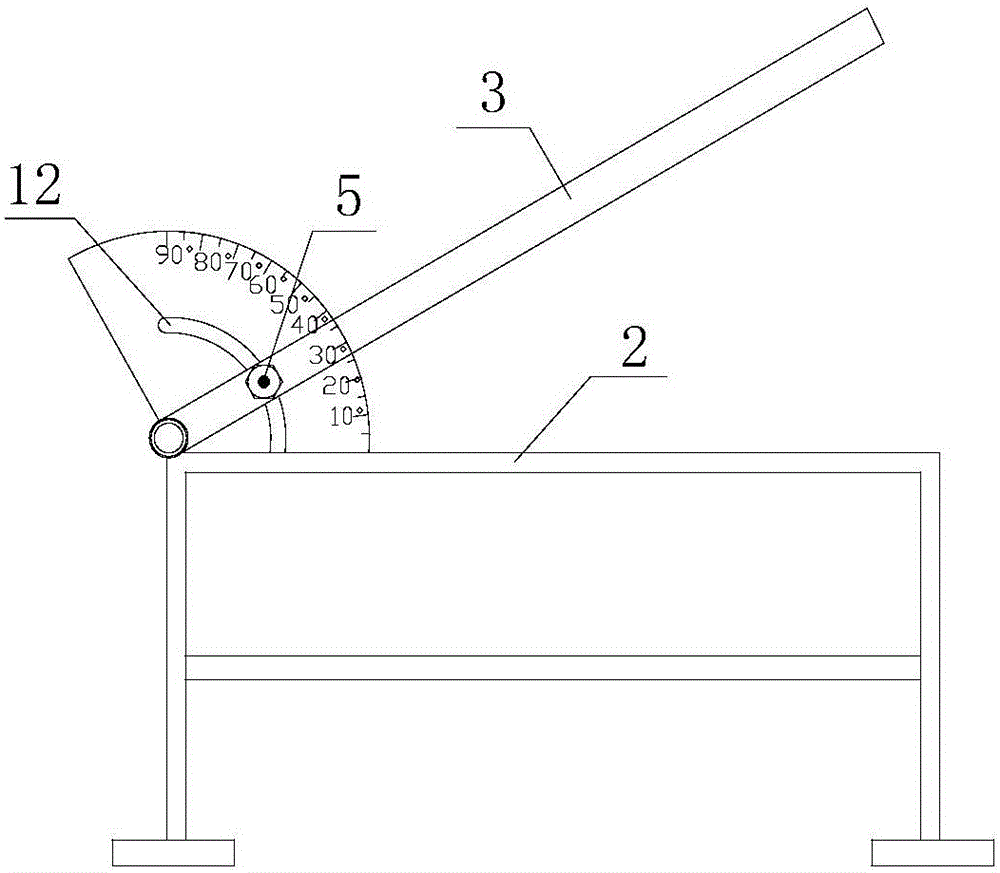

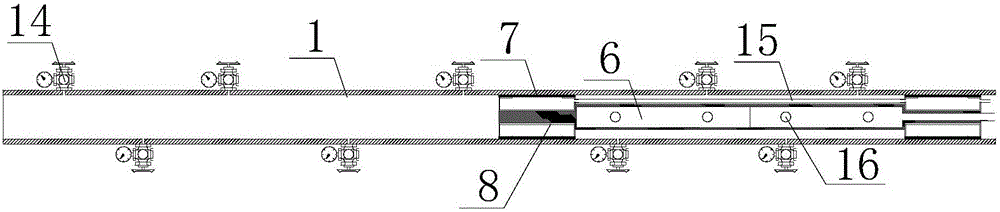

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Set the length of the test probe (that is, the length of the water injection section L) to 0.8 m, the plugging pressure to 2.0 MPa, the water injection pressure P to be 0.1 MPa, and the flow coefficient A to be 1.5, and the flow rate is carried out for the boreholes with the size of the cracks set in turn. Assay:

[0067] The first section (0-1m): the flow rate Q is 0.4L / min, and the corresponding permeability coefficient is 7.5m / d;

[0068] The second section (1-2m): the flow rate Q is 1.2L / min, and the corresponding permeability coefficient is 22.5m / d;

[0069] The third section (2-3m): the flow rate Q is 0.5L / min, and the corresponding permeability coefficient is 9.375m / d;

[0070] The fourth section (3-4m): the flow rate Q is 0.3L / min, and the corresponding permeability coefficient is 5.625m / d;

[0071] The fifth section (4-5m): the flow rate Q is 0.8L / min, and the corresponding permeability coefficient is 15m / d.

[0072] This example is only an illust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com