High voltage cable direct current leakage test method

A technology of DC leakage and test method, which is applied in the direction of measuring electricity, measuring electrical variables, and testing dielectric strength, etc., can solve the problems of long time and low efficiency, and achieve the goal of improving work efficiency, simplifying work steps, and reducing the length of the general wiring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

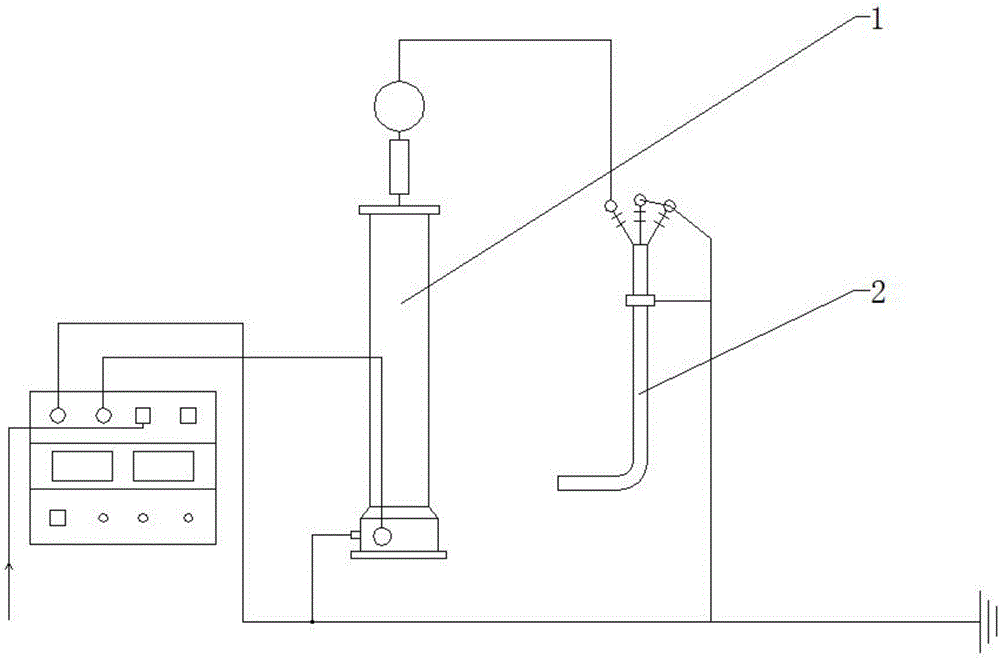

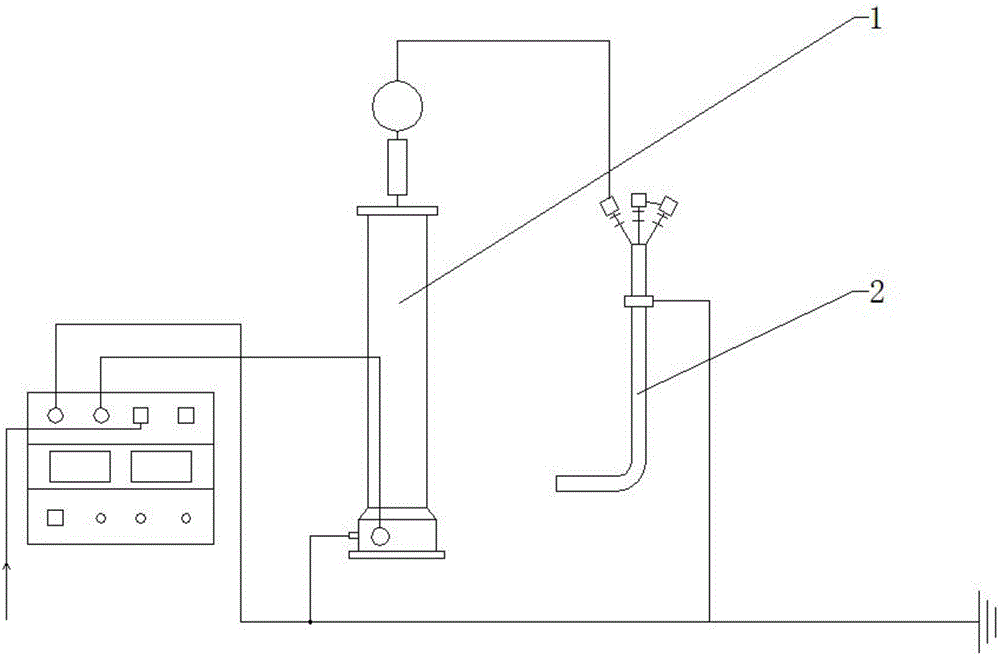

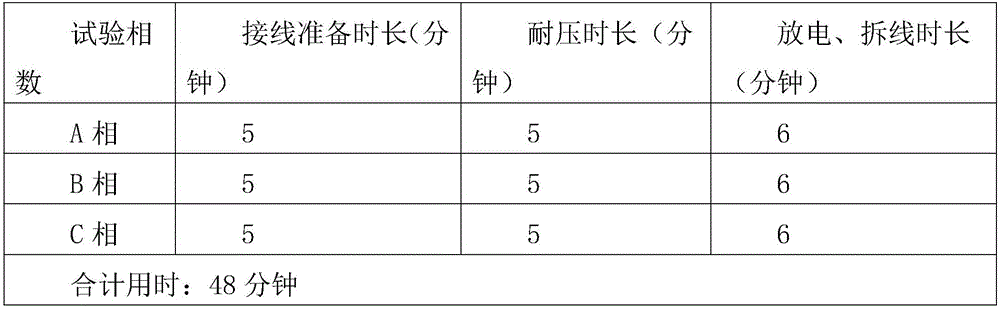

[0025] Embodiment 1: as figure 2 As shown, a high-voltage cable DC leakage test method includes the following steps:

[0026] A. Loosen the fixing screws of the cable 2, and fix the two ends of the cable 2 on a stable support according to the pressure resistance requirements, and spread the distance to the ground to a suitable position; use sandpaper to polish the copper rust of the cable 2 terminal, and use the terminal cloth to wipe clean;

[0027] B. Use the insulation resistance meter to distinguish the A phase, B phase and C phase of the cable 2, and mark it with a whiteboard marker;

[0028] C. Connect the test connection line of the DC high voltage generator 1 to the A-phase terminal of the cable 2, and connect the other end of the DC high voltage generator 1 to the ground wire of the cable 2, and the connection should be in good contact;

[0029] The connection between D and A phase terminals is tightly covered with insulating material;

[0030] E. Connect the B-ph...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap