Ultraviolet scattering agent and application therefor

A technology of ultraviolet rays and scattering agents, applied in the field of ultraviolet scattering agents, which can solve problems such as damaged gloss, increased concealment, and high specificity, and achieves excellent fluidity and excellent safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Hereinafter, synthesis examples, examples, and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to the following examples. In addition, the evaluation items in each of the following Examples and Comparative Examples were measured by the following methods.

[0182] (1) Aspect ratio of polymer particles

[0183] Using a scanning electron microscope (S-4800 manufactured by Hitachi High Technologies Co., Ltd.), photographs were taken at a measurable magnification (300 to 30,000 times), and the obtained elliptical or needle-shaped polymer particles were two-dimensionalized (should be It should be noted that, generally, the elliptical or needle-shaped polymer particles are kept in a state where the long axis direction is horizontal.), the major axis (L) and minor axis (D) of each particle are measured, and the aspect ratio (L / D) is calculated. , to calculate the average aspect ratio (P AV ).

[018...

Synthetic example 1

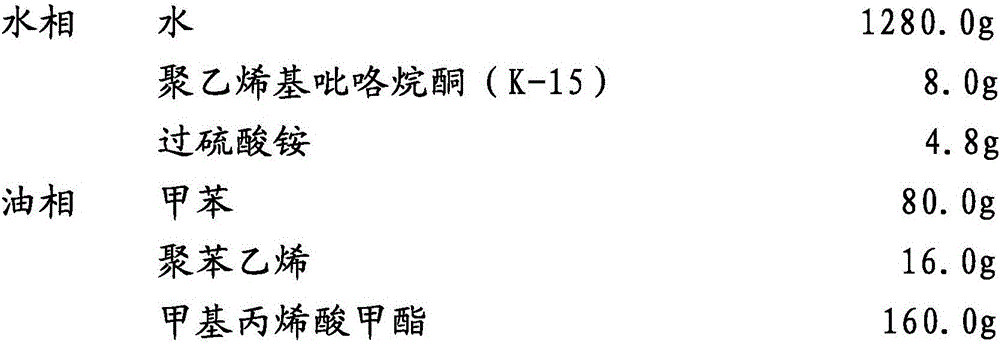

[0189] After dissolving the compounds shown below in each phase in a 2,000 mL flask, the water phase and the oil phase were mixed and charged, and heated and stirred (400 rpm) at an oil bath temperature of 80°C under a nitrogen stream for about 8 hours , A particle solution of polymethyl methacrylate was obtained.

[0190]

[0191] (Polystyrene: manufactured by Sigma Aldrich Co., weight average molecular weight about 45,000)

[0192] Next, the particle solution was washed with methanol-filtered five times using a known suction filter, and vacuum-dried to obtain polymer particles A1.

Synthetic example 2

[0194] Polymer particles A2 of polymethyl methacrylate were obtained in the same manner as in Synthesis Example 1 except that the polystyrene in the oil phase was changed to 12.0 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap