Slope greening spray seeding machine

A technology of seeding machine and slope, applied in the field of dry-type soil seeding machine, can solve the problems of unfavorable seed germination and growth, difficulty and low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

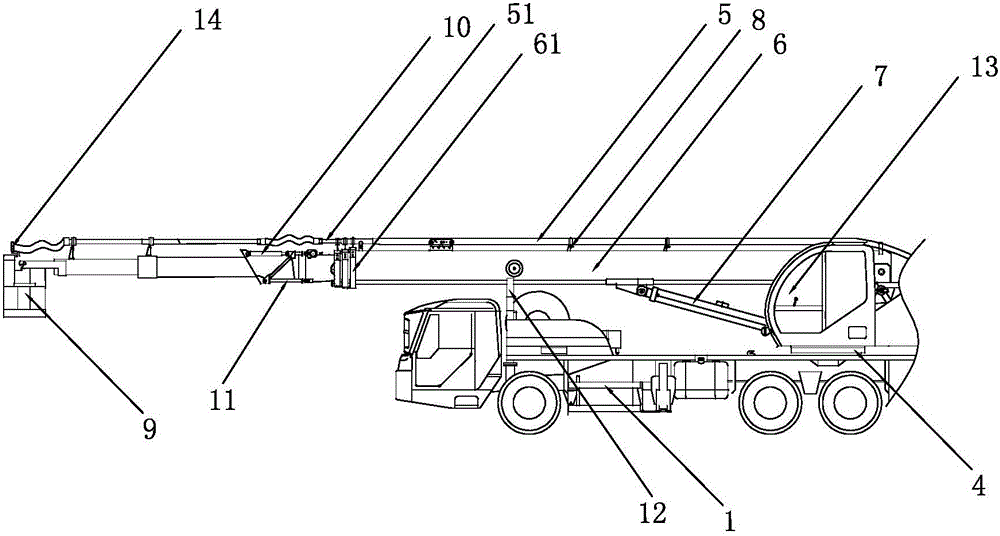

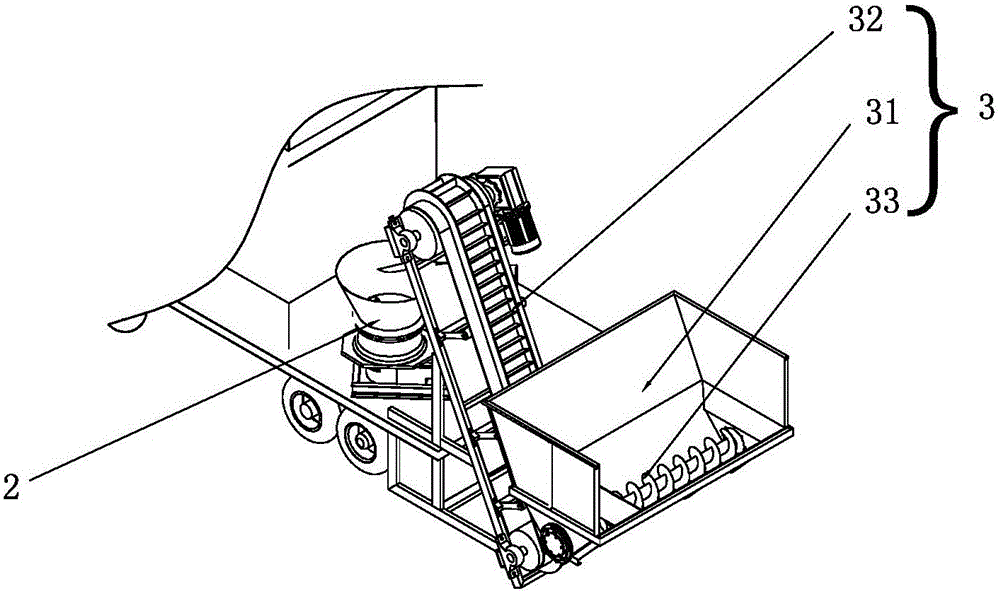

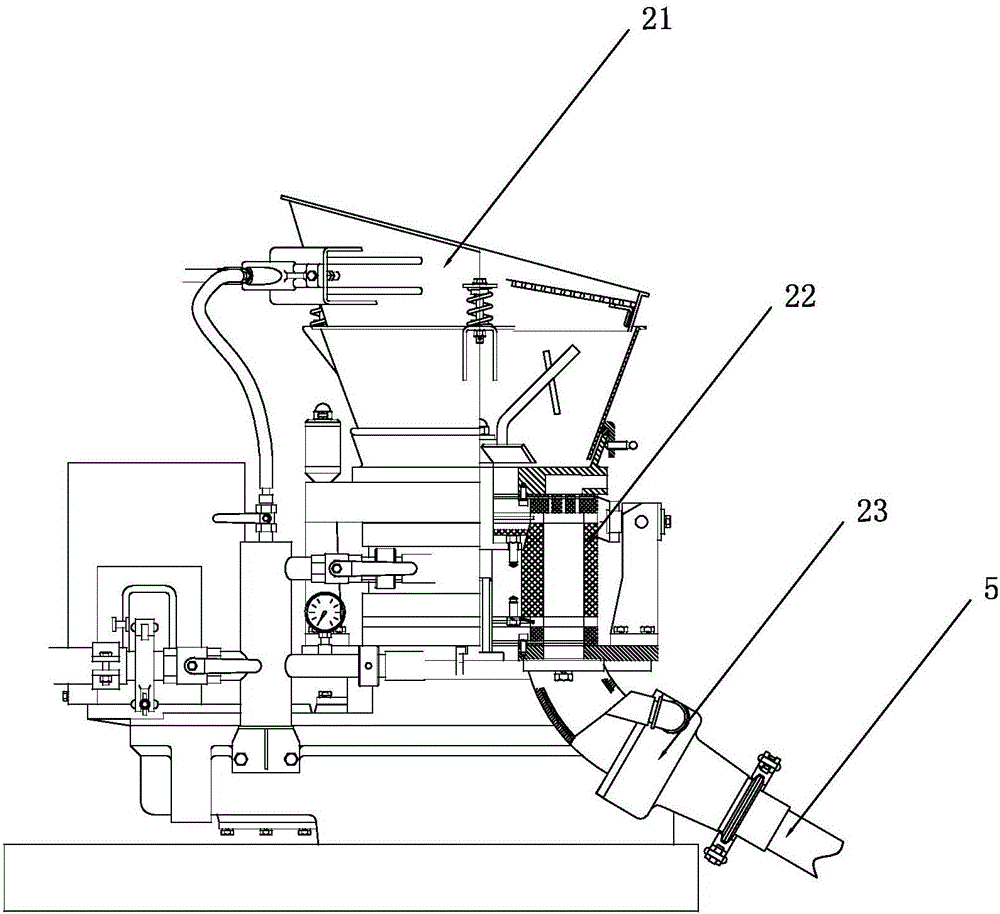

[0017] see figure 2 and image 3 , a kind of side slope regreening sprinkler of the present invention comprises a transport vehicle 1, a spray machine 2 installed at the rear of the transport vehicle 1, an air compressor, a feeding mechanism 3 and a turntable 4, and the spray machine 2 includes Hopper 21, stirring device 22 and feeding elbow 23, described feeding mechanism 3 comprises unloading hopper 31 and transmission frame 32, is provided with screw main shaft 33 and discharging opening in described unloading hopper 31, and described screw main shaft 33 will The foreign soil in the discharge hopper 31 moves evenly to the vicinity of the discharge port, and the transmission frame 32 transfers the foreign soil from the discharge port to the hopper 21, and the foreign soil in the hopper 21 falls into the stirring device 22 for further processing. Stirring, the output end of the stirring device 22 communicates with the air compressor, and the stirred soil is mixed with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com