A colorless low-sugar amino acid drink and its preparation process

A preparation process and amino acid technology, which is applied in the field of low-sugar amino acid beverages and its preparation, can solve the problems of unfitness for consumption, and achieve the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

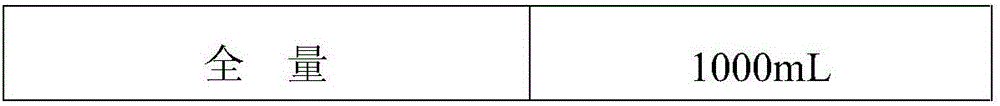

[0042] Weigh the materials according to the prescription in the table below.

[0043] Compound Amino Acid Powder 11g stachyose 3g Vitamin B6 1.60mg Vitamin B12 1.80μg ethyl maltol 0.75g Sorbitol 15g citric acid 0.1g Acesulfame K 0.09g Potassium sorbate 0.1g sodium bisulfite 0.2g purified water Appropriate amount Full amount 1000mL

[0044] The compounding process comprises the following steps:

[0045] Add 1 / 3 of the prepared amount of purified water to the first concentrated preparation tank, heat the purified water to 90-100°C, keep it for at least 3 minutes, then cool down to 70-80°C, add the prescribed amount of compound amino acid powder, and stir After dissolving, add the prescribed amount of ethyl maltitol, sorbitol, stachyose, citric acid and stir to dissolve, then keep the temperature at 60-65°C, add the prescribed amount of vitamin B6, vitamin B12, acesulfame potassium , potassium sorb...

Embodiment 2

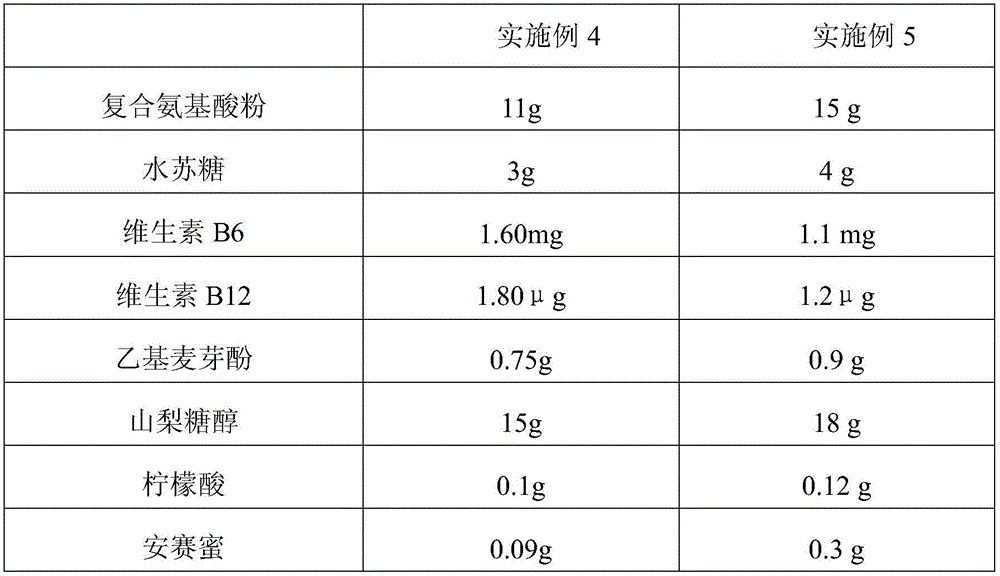

[0050] Weigh the materials according to the prescription in the table below.

[0051]

[0052]

[0053] The compounding process comprises the following steps:

[0054] A. Concentrated preparation steps:

[0055] Add 1 / 3 of the prepared amount of purified water to the first concentrated preparation tank, heat the purified water to 90-100°C, keep it for at least 3 minutes, then cool down to 70-80°C, add the prescribed amount of compound amino acid powder, and stir After dissolving, add ethyl maltitol, sorbitol, and stachyose in the prescribed amount and stir to dissolve, add 0.2% (W / V) activated carbon, keep mixing at 65-70°C for 15-30 minutes, decarbonize and filter to obtain The primary filtrate, the primary filtrate is collected in the second concentrated tank, and then 0.2% (W / V) activated carbon is added, kept at 65-70 °C and mixed for 15-30 minutes, decarbonized and filtered to the third concentrated tank to obtain Secondary filtrate, the secondary filtrate is deca...

Embodiment 3

[0062] Weigh the materials according to the prescription in the table below.

[0063] Compound Amino Acid Powder 11g stachyose 3g Vitamin B6 1.60mg Vitamin B12 1.80μg ethyl maltol 0.75g Sorbitol 15g citric acid 0.1g Acesulfame K 0.09g Potassium sorbate 0.1g purified water Appropriate amount Full amount 1000mL

[0064] The compounding process comprises the following steps:

[0065] A. Concentrated preparation steps:

[0066] Add 1 / 3 of the prepared amount of purified water to the first concentrated preparation tank, heat the purified water to 90-100°C, keep it for at least 3 minutes, then cool down to 70-80°C, add the prescribed amount of compound amino acid powder, and stir After dissolving, add ethyl maltitol, sorbitol, stachyose, and citric acid in the prescribed amount and stir to dissolve, add 0.2% (W / V) activated carbon, keep mixing at 65-70°C for 15-30 minutes, remove Filtrate with charcoal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com