Falling-film evaporator for preparing spices

A technology of falling film evaporator and spices, which is applied in the direction of evaporator accessories, evaporation, steam pressurized evaporation, etc. It can solve the problems of waste of resources, high cost, and inability to complete work tasks in one step, and achieve short residence time and low energy consumption. consumption, improve practicality and create value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

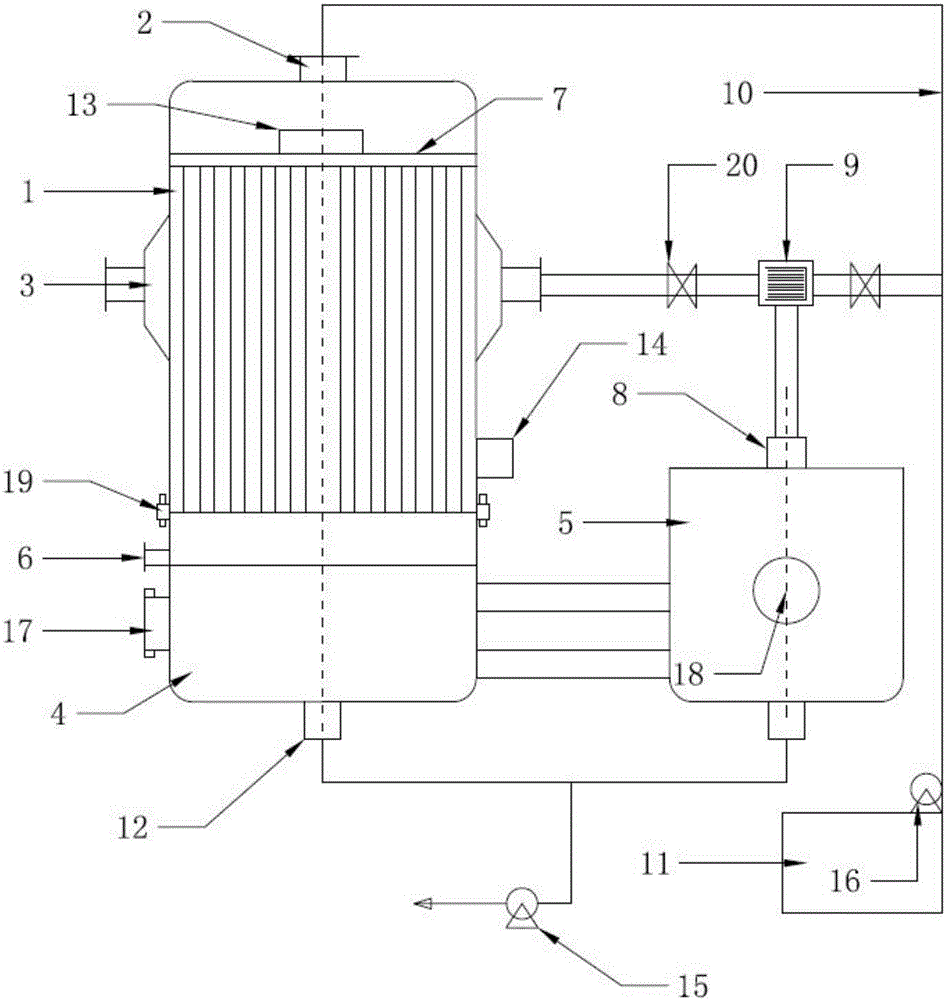

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0017] A falling film evaporator for perfumery, comprising an evaporation chamber 1, a heat exchange tube bundle is arranged in the evaporation chamber 1, a vapor-liquid separator 4 is arranged under the evaporation chamber 1, and a steam inlet 3, a condensing Water outlet 6, condenser 14, the top of the evaporation chamber 1 is provided with a material inlet 2, the bottom of the material inlet 2 is provided with a material distributor 7, and the gas-liquid separator 4 is connected to the separation chamber 5 through two pipes parallel up and down. The top of the separation chamber 5 is provided with a secondary steam outlet 8, the secondary steam outlet 8 is connected to a compressor 9, and the compressor 9 is connected to two pipelines, one of which is connected to the steam inlet 3, and the other pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com