Full-automatic cleaning machine for liquid crystal glass substrates

A liquid crystal glass substrate, fully automatic cleaning technology, applied in the field of cleaning machines, can solve the problems of uneven glass substrate cleaning, glass substrate slippage, etc., to achieve the effect of high cleaning efficiency and cleanliness, smooth and even transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

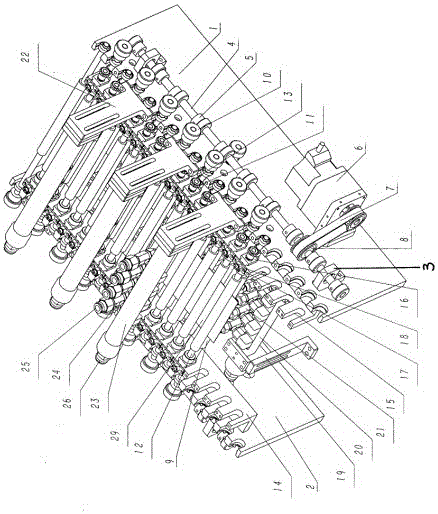

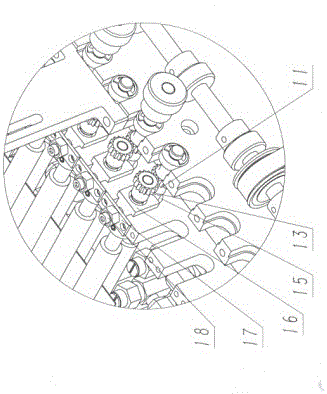

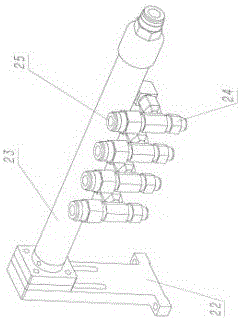

[0014] A liquid crystal glass substrate automatic cleaning machine, comprising a glass substrate cleaning conveyor belt right bracket 1 and a glass substrate cleaning conveyor belt left bracket 2 arranged parallel to each other, a pair of double-sided bearing seats are arranged on the outer surface of the glass substrate cleaning conveyor belt right bracket 1 3. A transmission gear shaft 4 is set in a pair of double-sided bearing seats 3, and a threaded staggered lower gear 5 is set on the transmission gear shaft 4, and the outer surface of the right bracket 1 of the glass substrate cleaning conveyor belt under the transmission gear shaft 4 A driving motor 6 is provided, and the driving motor 6 is connected with the synchronous pulley 8 on the transmission gear shaft 4 through a synchronous belt 7. A right U-shaped groove is arranged on the top of the right bracket 1 of the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com