High-precision multi-station drilling device

A drilling device and high-precision technology, applied in boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of unsecured drilling position accuracy and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

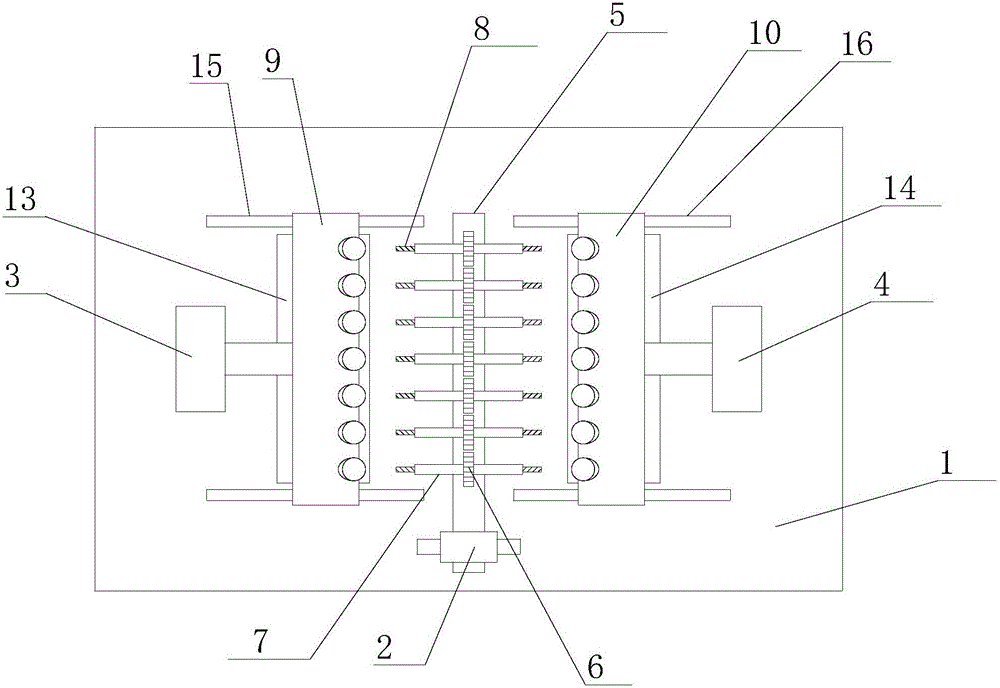

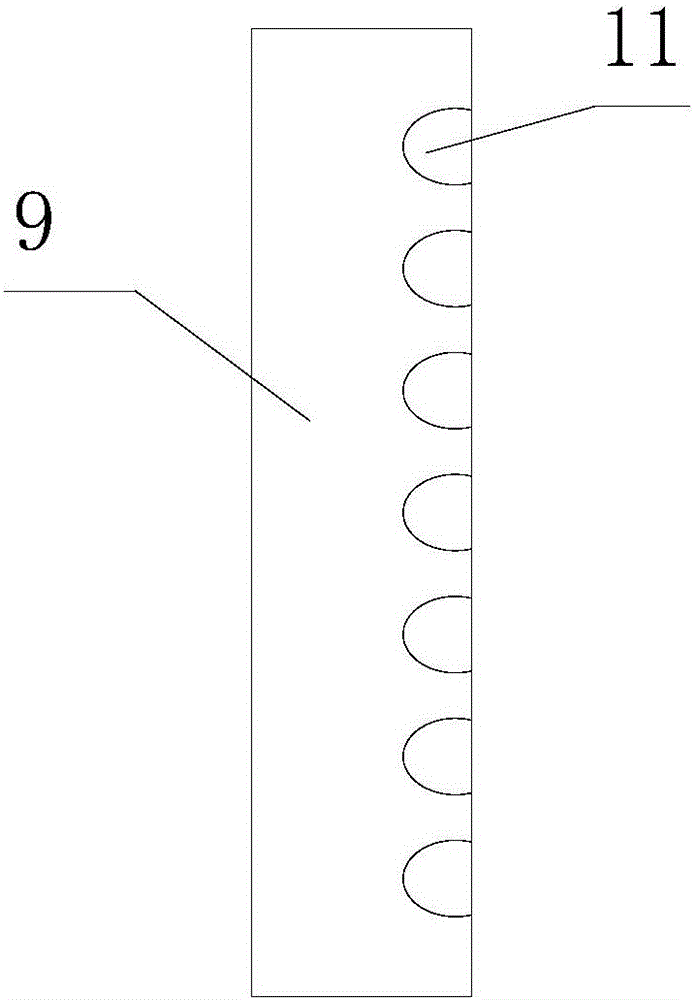

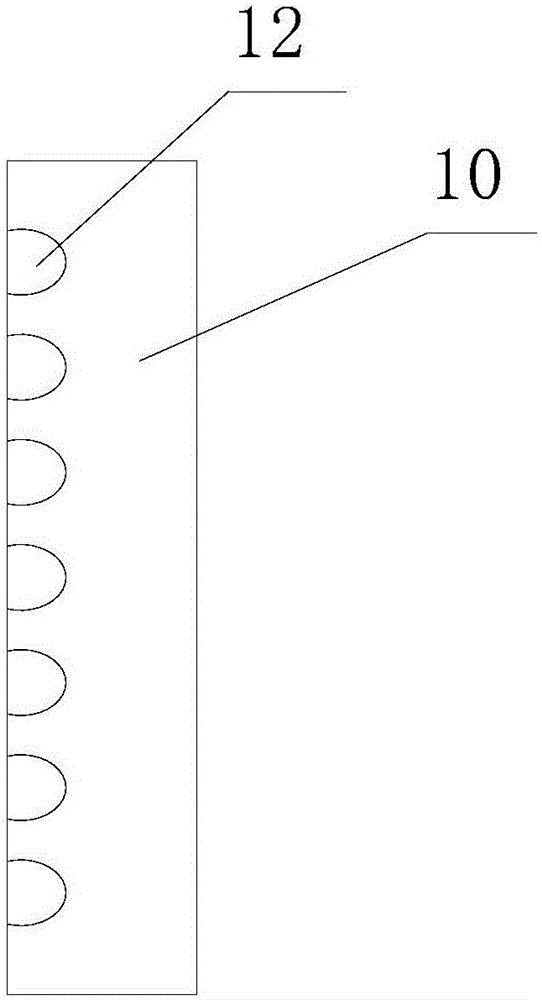

[0017] refer to figure 1 , figure 2 , image 3 , the present invention proposes a high-precision multi-station drilling device, including a workbench 1, a drilling mechanism, a first workpiece fixing mechanism, a second workpiece fixing mechanism, a first driving mechanism 2, a second driving mechanism 3, a third Drive mechanism 4, the first distance measuring sensor, the second distance measuring sensor and the control mechanism, wherein:

[0018] The drilling mechanism includes a rack 5, a plurality of gears 6, and a plurality of drill rods 7. The rack 5 is arranged on the workbench 1, and the first driving mechanism 2 is connected with the rack 5 and drives the rack 5 to move; a plurality of gears 6 Arranged side by side along the moving direction of the rack 5 and a plurality of gears 6 are all meshed with the rack 5, and the movement of the rack 5 drives the gear 6 to rotate; the number of the drill rods 7 is consistent with the number of the gears 6, and the drill rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com