Rolling cutter

A cutting tool and rolling cutting technology, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult production and processing of rolling cutting tools, inconvenient blade replacement and repair, and large cutting load, so as to facilitate heat dissipation, Easy replacement and repair, short contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

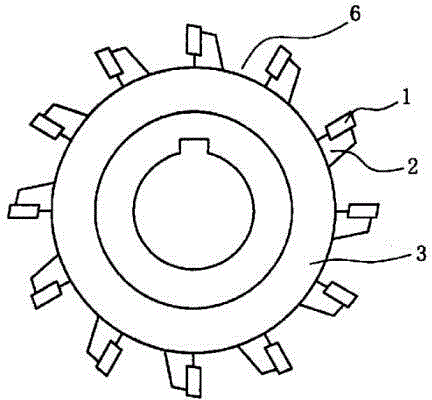

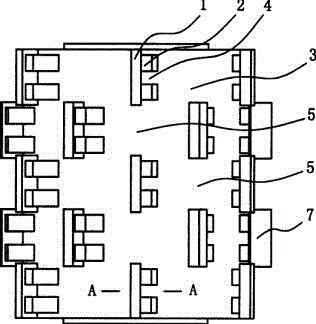

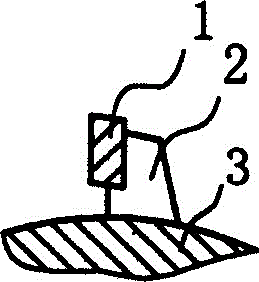

[0011] Hobbing cutting tool, cutter body 3 is provided with blade seat 2, and blade seat 2 is fixed with blade 1, and blade seat 2 is vertically arranged alternately on the outer circular surface of cutter body 3 so that there is a longitudinal distance 5 between longitudinally adjacent blades 1, and the blade Seats 2 are alternately arranged on the outer surface of the cutter body 3 in the circumferential direction so that there is a circumferential distance 6 between the circumferentially adjacent blade seats 2. The longitudinal spacing 5 is smaller than the width of the cutting surface 7 of the blade 1, which can make the cutting surface complete and smooth, and the middle of the blade seat 2 is provided with a cooling groove 4.

[0012] The present invention is not limited to the above-mentioned specific implementation manners, and various transformations made by those skilled in the art starting from the above-mentioned concept without creative work all fall within the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap