Basin type insulator assembling clamp

A technology for assembling fixtures and insulator pots, which is applied to assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of unsafe high-altitude operations, high labor costs, and low efficiency in the assembly process of pot-type insulators, so as to improve assembly quality, Low labor intensity, safe and reliable effect of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

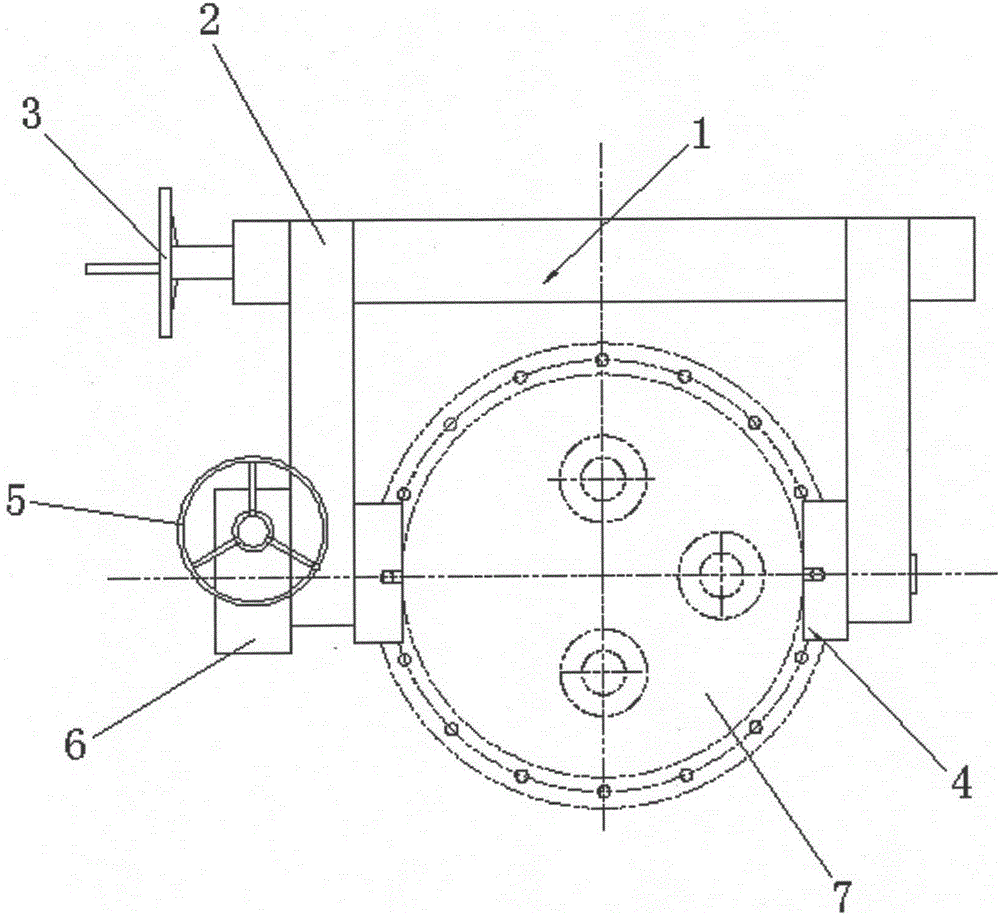

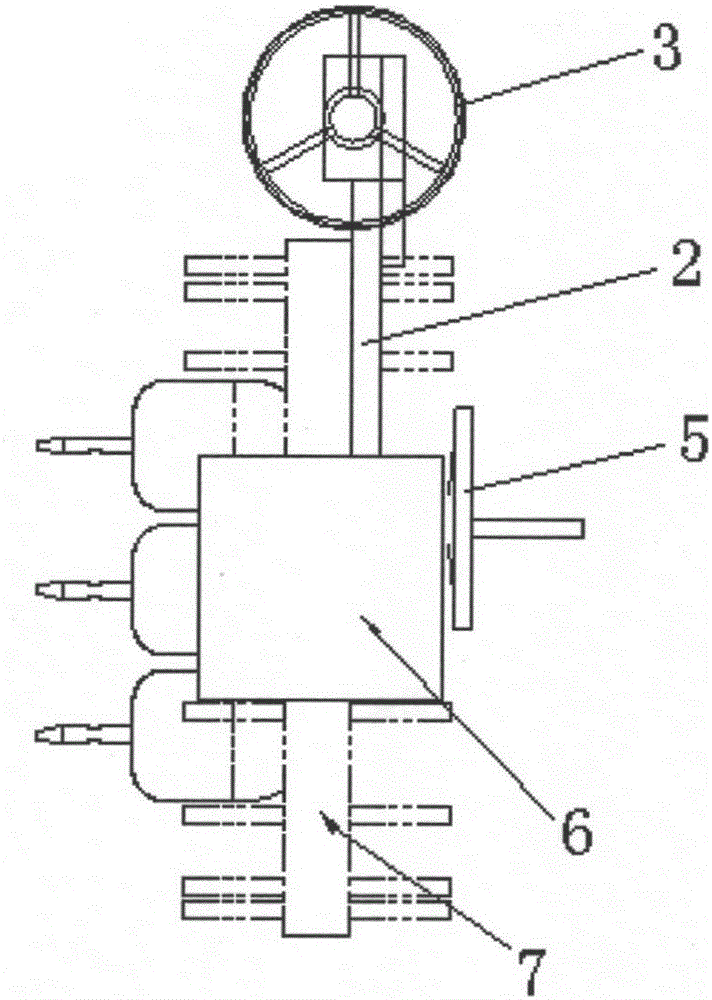

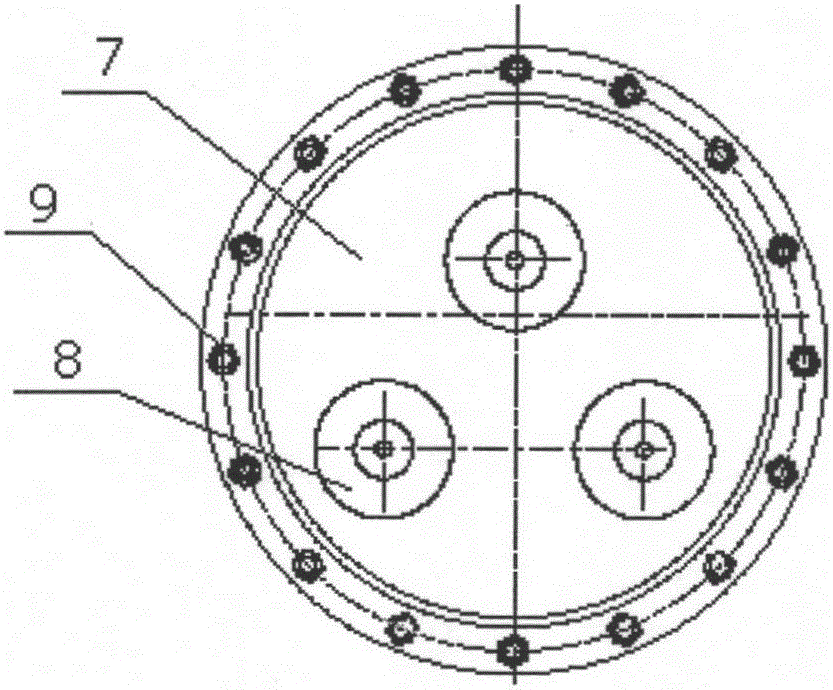

[0015] Such as figure 1 As shown, an insulating basin assembly fixture provided in this embodiment includes a linear module 1, and a pair of cantilevers 2 that can move relatively and a hand wheel for adjusting the relative positions of the two cantilevers 2 are provided on the linear module 1. One 3; one of the cantilever 2 is provided with a worm gear box 6 for turning over the pot insulator 7, and the worm gear box 6 is provided with a hand wheel 2 5. The opposite side of the cantilever 2 is provided with a clamping block 4 for clamping the pot insulator 7 .

[0016] Rotate the handwheel one 3 to separate the two cantilevers 2, then move the fixture to the outside of the pot insulator 7, and rotate the handwheel one 3 in the opposite direction, the two clamping blocks 4 on the cantilever 2 clamp the outer edge of the pot insulator 7, The smaller the distance between the cantilevers 2, the greater the clamping force of the clamp block 4 to clamp the pot insulator 7, until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com