Complex pull-out mechanism

A compound and unified technology, applied in the field of machinery, can solve the problems of difficult bearing disassembly, damage to the bearing seat or shaft, and poor disassembly effect, so as to achieve the effect of saving time and labor, high use efficiency and simple manufacturing process for disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

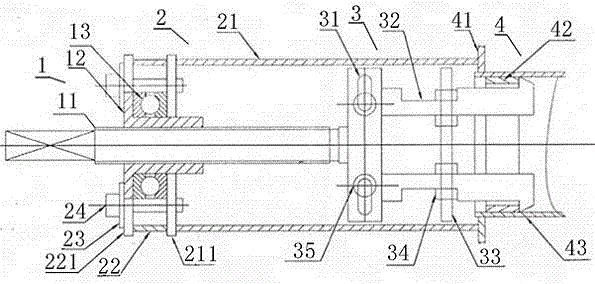

[0031] Bearing outer ring pull-out mechanism.

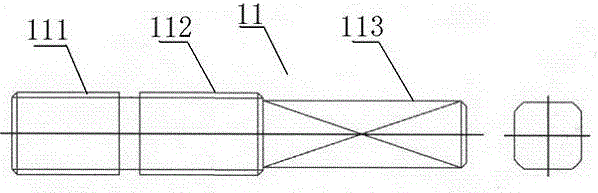

[0032] The present invention as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown, the bearing outer ring pull-out mechanism. It includes a transmission component 1, a support component 2, a linkage component I and a bearing outer ring component 4. The transmission assembly 1 includes a lead screw 11 , a lead screw nut 12 and a thrust ball bearing 13 . The lead screw 11 is a double-handed equal-pitch thread structure, the thrust ball bearing 13 is sleeved on the lead screw nut 12 , and the lead screw nut 12 is matched and screwed to the left-hand thread section 112 of the lead screw 11 .

[0033] The support assembly 2 includes a support cylinder 21 , a support cylinder cover 211 symmetrically arranged up and down on the support cylinder 21 , an anti-rotation cover seat 22 and an anti-rotation cover 221 . A washer 23 is provided on the anti-rotation cover plate 221 to limit the axial s...

Embodiment 2

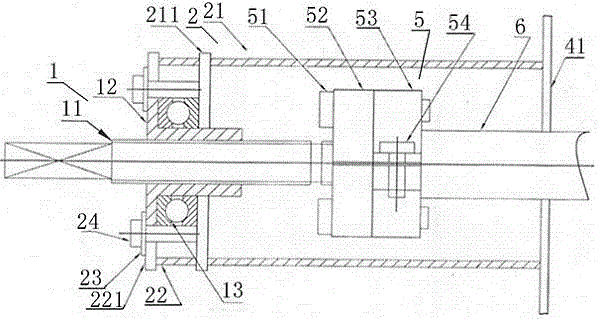

[0037] Half shaft pull-out mechanism.

[0038] The present invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 8 , Figure 10 as shown,

[0039] A half-shaft pull-out mechanism, the transmission assembly 1 and the support assembly 2 have the same structure as that of embodiment 1,

[0040]The difference is that a linkage assembly II is also provided, and the linkage assembly II includes a connecting pull plate 52 and a split nut 53 . The connecting pull plate 52 is screwed to the right-handed thread section 111 of the lead screw 11, and the two ends of the connecting pull plate 52 are detachably and fixedly connected to the two ends of the split nut 53 through the screw rod III, and the split nut 53 is screwed on the half shaft 6 On, the screw rod IV is used to connect the upper and lower parts of the half nut 53.

[0041] The present invention is manufactured by forging and machining.

[0042] The material used for the screw, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com