Four-degree-of-freedom parallel mechanism

A degree of freedom and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of many singular configurations, limited working space, and difficult processing, and achieve less singular configurations, good dynamic response, Achieve lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

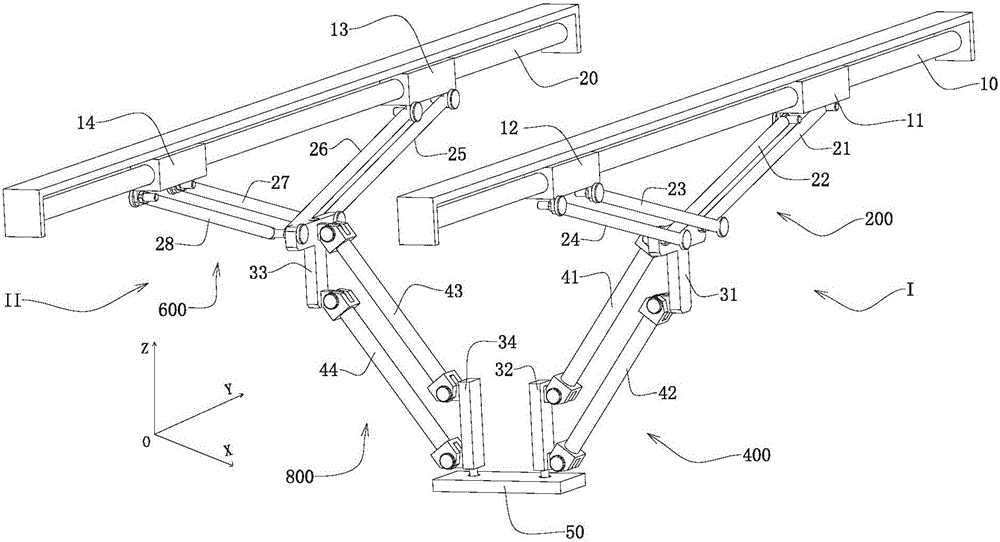

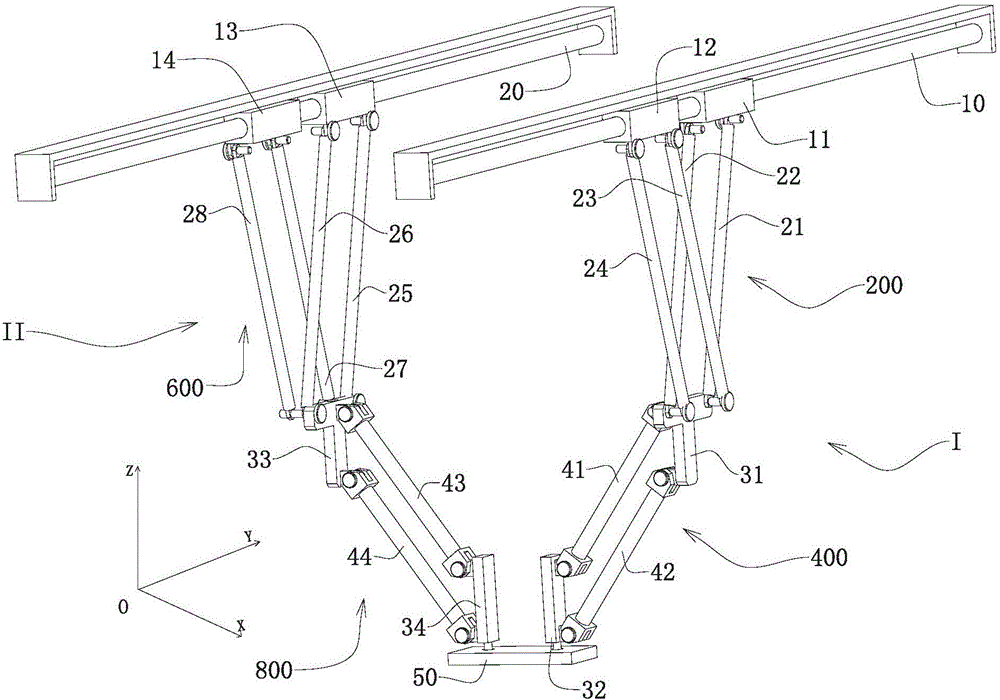

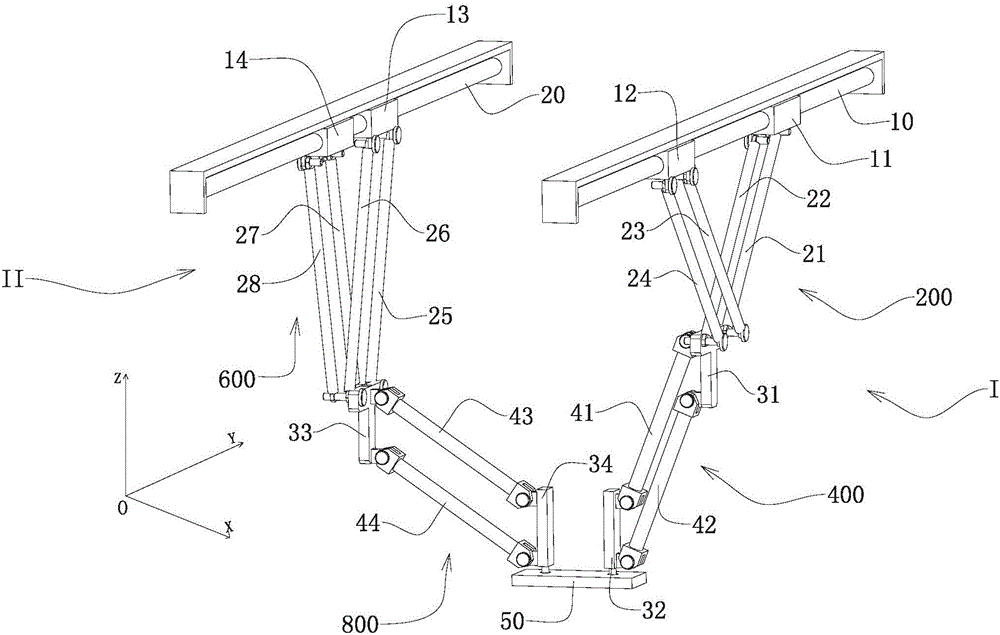

[0040] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings in order to understand the purpose, features and advantages of the present invention more clearly. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but merely to illustrate the essential spirit of the technical solution of the present invention.

[0041] Term description:

[0042] The first plane: refers to the plane parallel to the YOZ plane in the coordinate system of the drawings in this article;

[0043] The second plane: refers to the plane parallel to the XOZ plane in the coordinate system of the drawings in this article.

[0044] The parallel mechanism of the present invention usually includes a fixed platform, a moving platform, a first branch chain and a second branch chain. The first branch chain and the second branch chain are respectively connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com