A new type of cloth machine and cloth method

A distributing machine, a new type of technology, applied in the direction of coatings, household appliances, and other household appliances, can solve the problems of single-color quartz stone that cannot meet the aesthetic needs of consumers, dull texture, and insufficient layering, so as to reduce manual leveling Plate work, texture criss-cross realistic, multi-color lines clear and natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

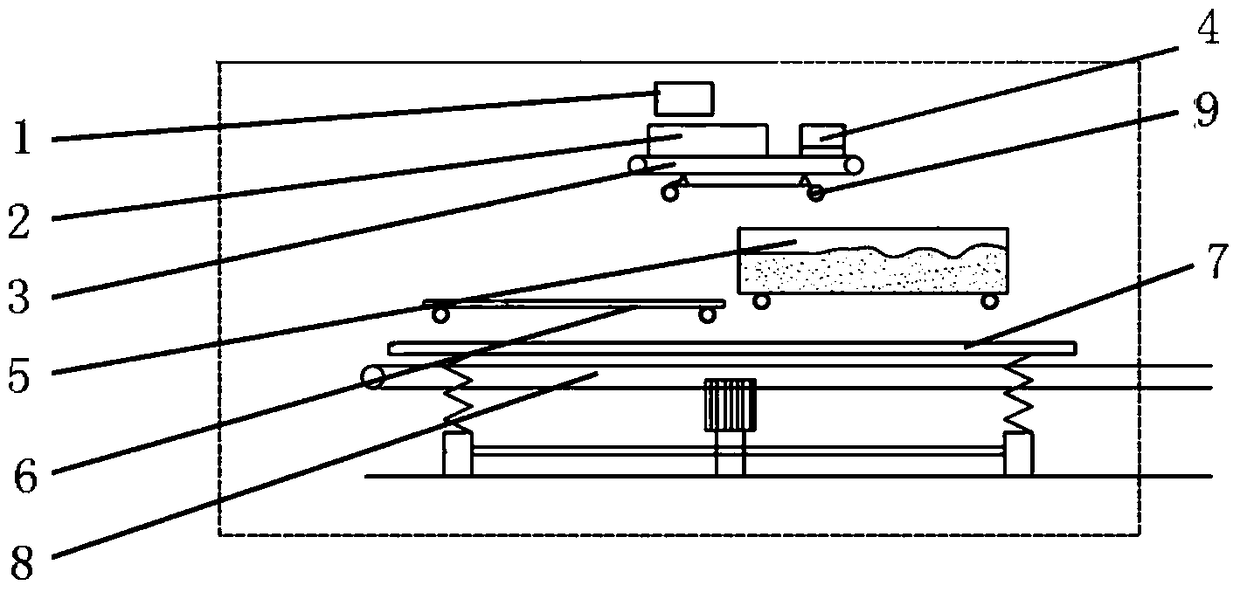

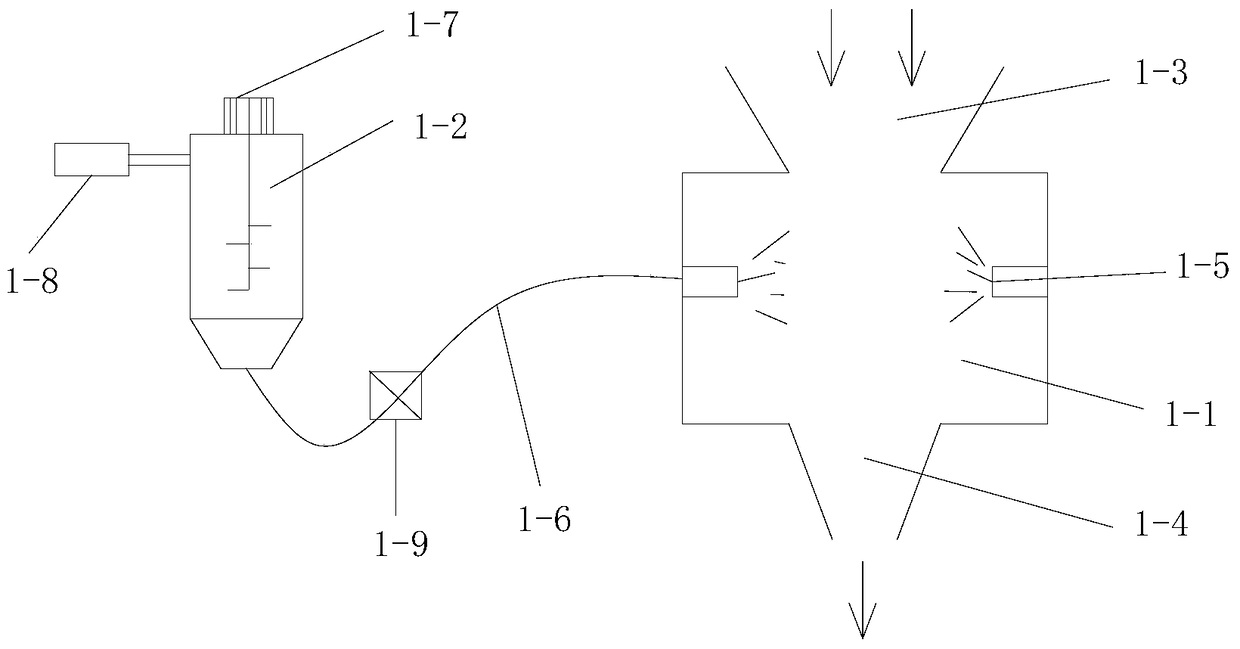

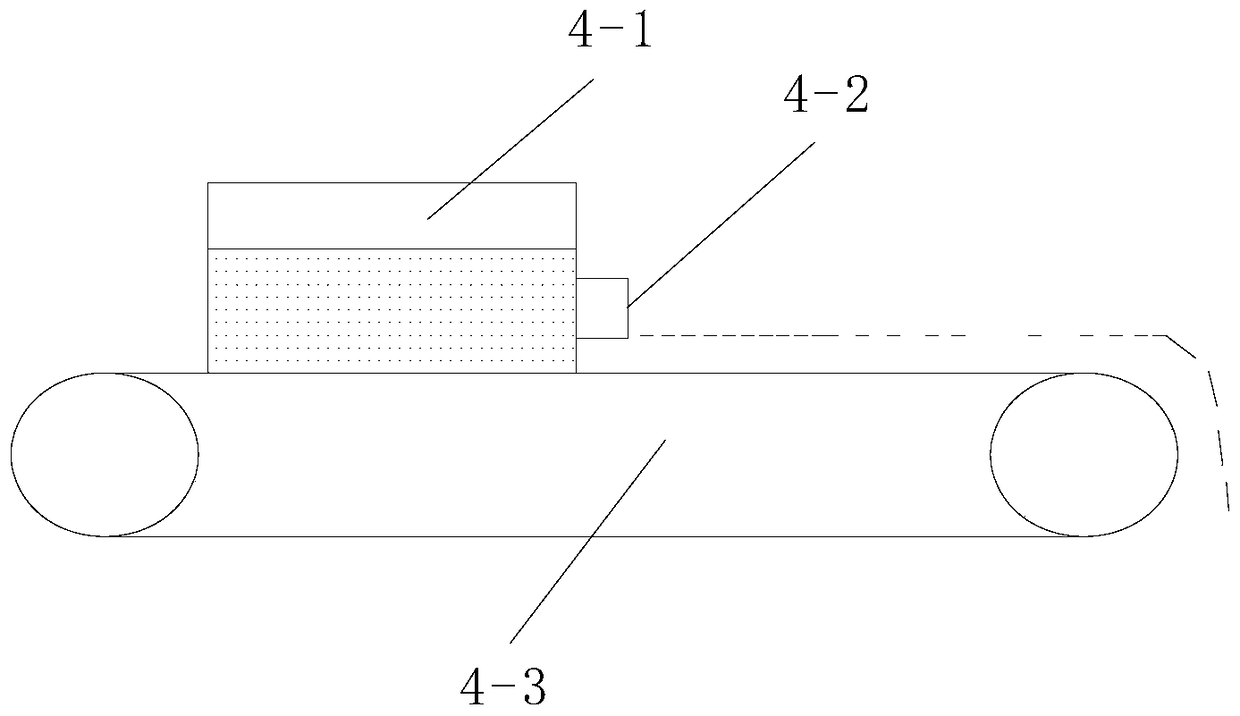

[0033] Such as figure 1 As shown, a new type of distribution machine includes: first spraying or powder distribution equipment 1, hopper 2, belt conveyor 3, second spraying or powder distribution equipment 4, mobile storage hopper 5, mobile cutter 6 and lifting Mechanism 7, the first spraying or powder distribution equipment 1 is used to transport the raw materials into the hopper 2 and spray into the color paste or toner during the transport process, and the belt conveyor 3 is used to transport the raw materials in the hopper 2 In the mobile storage hopper 5, the second spraying or powder distribution equipment 4 is arranged above the belt conveyor 2 to spray color paste or toner on the raw materials transported by the belt conveyor 2, and the mobile cutter 6 constitutes a mobile The lower closed surface of the storage hopper 5, the lifting mechanism 7 is connected with the mobile storage hopper 5, and a press belt 8 is also provided below the mobile storage hopper 5.

[003...

Embodiment 2

[0046] This embodiment provides a new type of distribution machine which is basically the same as Embodiment 1, the difference is:

[0047] Such as Figure 4 As shown, a pressure roller 10 and a roller knife 11 are arranged above the belt conveyor 3, the pressure roller 10 is used to flatten the raw material output in the hopper 2, and the roller knife 11 is used to cut the flattened raw material Make a slot so that the color paste or color material sprayed by the second spraying or powder distribution equipment 4 can fully contact with the raw material, so as to improve the line pattern effect of the quartz stone plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com