Metal workpiece mark printing device

A technology for printing devices and metal workpieces, applied in printing, stamping and other directions, can solve problems such as affecting construction, increasing production costs, and strengthening overall structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

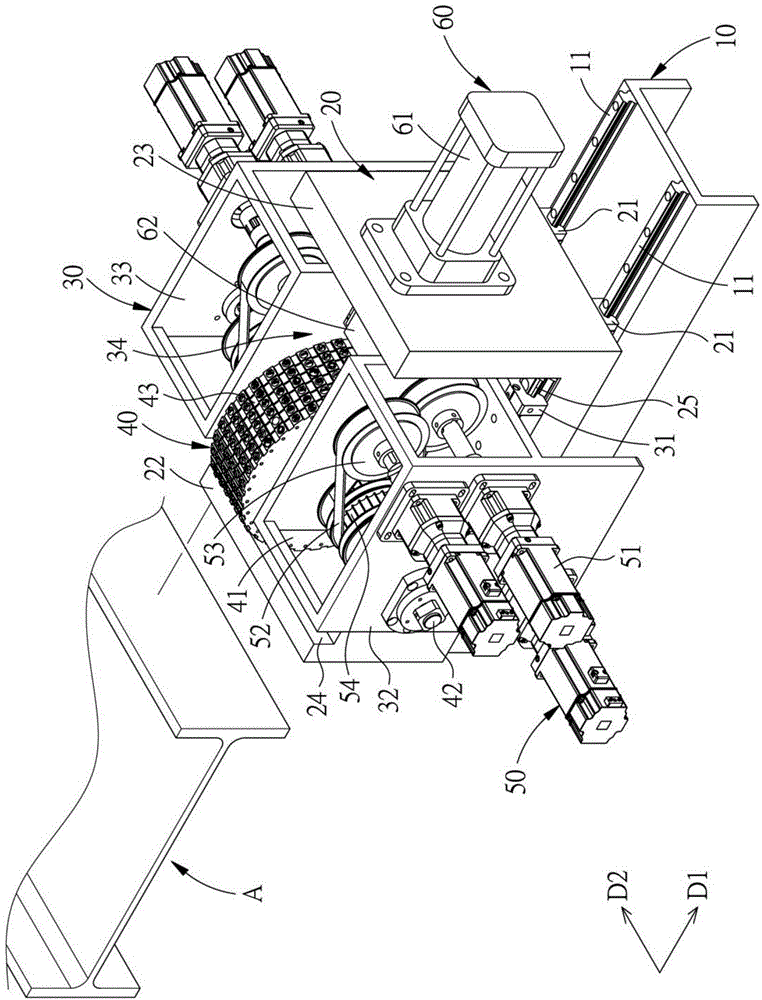

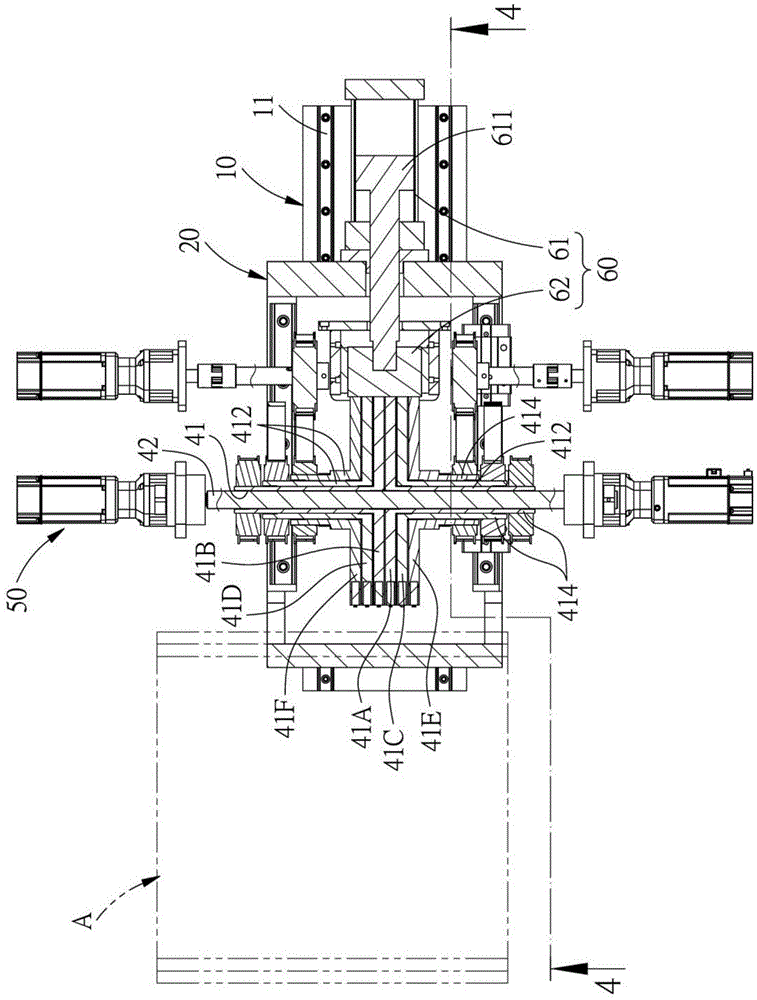

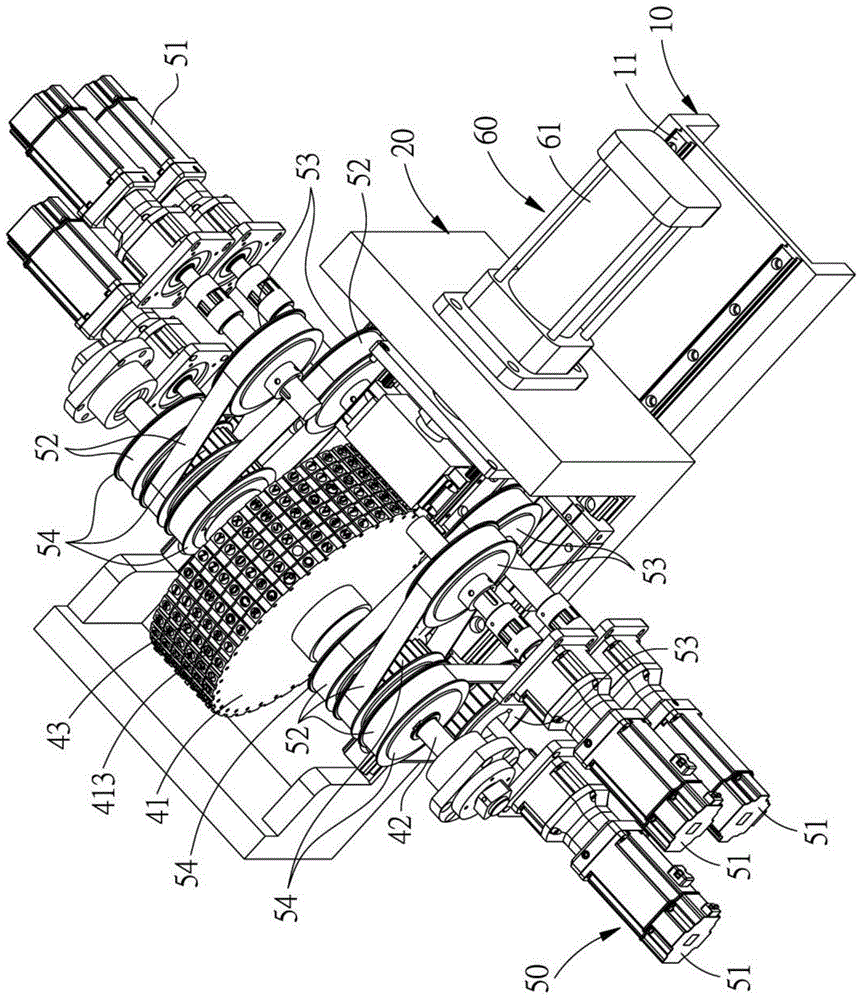

[0040] A preferred embodiment of the marking and printing device for metal workpieces of the present invention is as follows Figure 1 to Figure 5 shown, including:

[0041] A base 10 has a plurality of base slide rails 11 , each of the base slide rails 11 extends along a first direction D1 , and defines a second direction D2 perpendicular to the first direction D1 .

[0042] A device seat 20 is slidably covered on each of the base slide rails 11 with a plurality of device seat sliders 21, so that the device seat 20 can slide on the base 10, and the device seat 20 has Opposed to a workpiece contact surface 22 and a side surface 23, and the two ends of the workpiece contact surface 22 are respectively formed with a step 24, and a plurality of devices are further arranged between the workpiece contact surface 22 and the side surface 23 of the device seat 20. The seat slide rails 25 , each of the device seat slide rails 25 is extended along the first direction D1.

[0043] A sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com