Automatic paper feeding device of tissue paper machine

A paper feeding device and conveying device technology, which is used in transportation and packaging, coiling strips, and thin material handling, etc., can solve problems such as the inability to change pressure in time, embossing deformation of paper rolls, and uneven cross-section, etc. speed, ensure production quality and production efficiency, and ensure the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

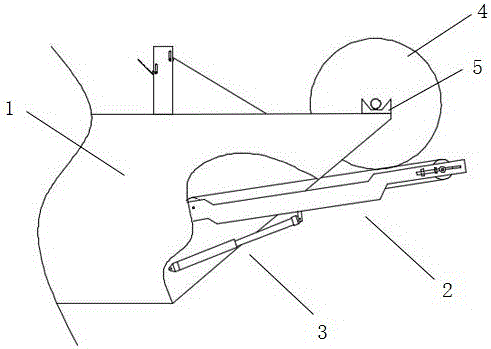

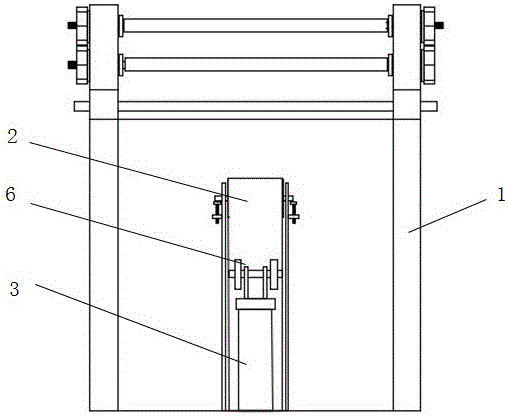

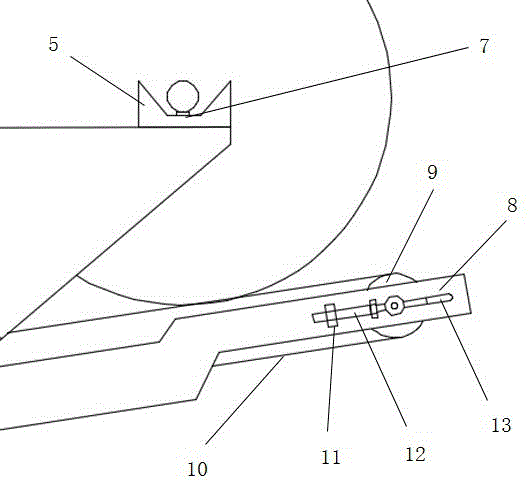

[0018] Embodiment 1: An automatic paper feeding device for a paper towel machine, which is arranged at the front end of the paper towel machine, and is used to provide paper towels for the paper towel machine, including a frame 1, a conveying device 2 and a supporting device 3, and the frame 1 is provided with There is a groove 5 for erecting the paper roll 4; the conveying device 2 can provide power for the paper roll 4 to convey the paper towel to the paper towel machine; the supporting device 3 is used to support the conveying device 2; the bottom of the groove 5 is provided There is a weight sensor 7 for monitoring the weight of the paper roll 4 and generating an electrical signal; the supporting device 3 includes a controller; the controller is connected with the weight sensor 7 and receives an electrical signal from the weight sensor 7, And control the supporting device 3 to provide proper supporting force, and adjust the pressure between the conveying device 2 and the pa...

Embodiment 2

[0019] Embodiment 2: An automatic paper feeding device for a paper towel machine, which is arranged at the front end of the paper towel machine for providing paper towels to the paper towel machine, including a frame 1, a conveying device 2 and a supporting device 3, and the frame 1 is provided with There is a groove 5 for erecting the paper roll 4; the conveying device 2 can provide power for the paper roll 4 to convey the paper towel to the paper towel machine; the supporting device 3 is used to support the conveying device 2; the bottom of the groove 5 is provided There is a weight sensor 7 for monitoring the weight of the paper roll 4 and generating an electrical signal; the supporting device 3 includes a controller; the controller is connected with the weight sensor 7 and receives an electrical signal from the weight sensor 7, And control supporting device 3 provides suitable supporting force, regulates the pressure between conveying device 2 and paper roll 4, and describe...

Embodiment 3

[0020] Embodiment 3: An automatic paper feeding device of a paper towel machine, which is arranged at the front end of the paper towel machine, and is used to provide paper towels to the paper towel machine, including a frame 1, a conveying device 2 and a supporting device 3, and the frame 1 is provided with There is a groove 5 for erecting the paper roll 4; the conveying device 2 can provide power for the paper roll 4 to convey the paper towel to the paper towel machine; the supporting device 3 is used to support the conveying device 2; the bottom of the groove 5 is provided There is a weight sensor 7 for monitoring the weight of the paper roll 4 and generating an electrical signal; the supporting device 3 includes a controller; the controller is connected with the weight sensor 7 and receives an electrical signal from the weight sensor 7, And control the supporting device 3 to provide appropriate supporting force, adjust the pressure between the conveying device 2 and the pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com