3D printer for printing glass body and printing method thereof

A 3D printer, glass body technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as reducing aesthetics and opacity, and achieve the effect of increasing printing speed, improving curing, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

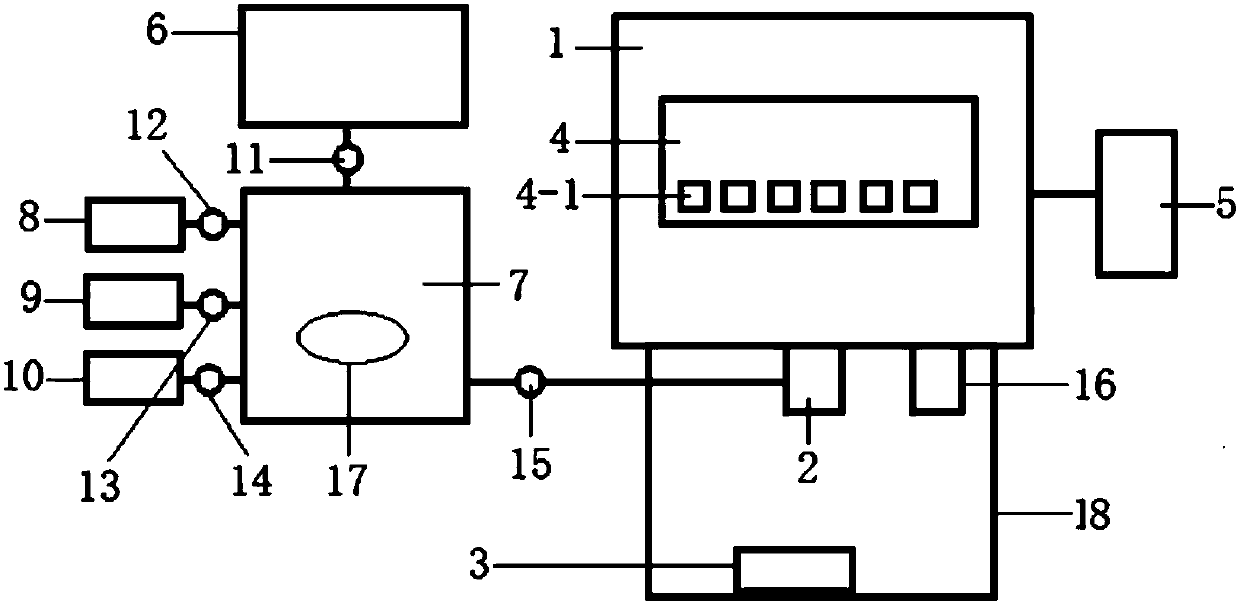

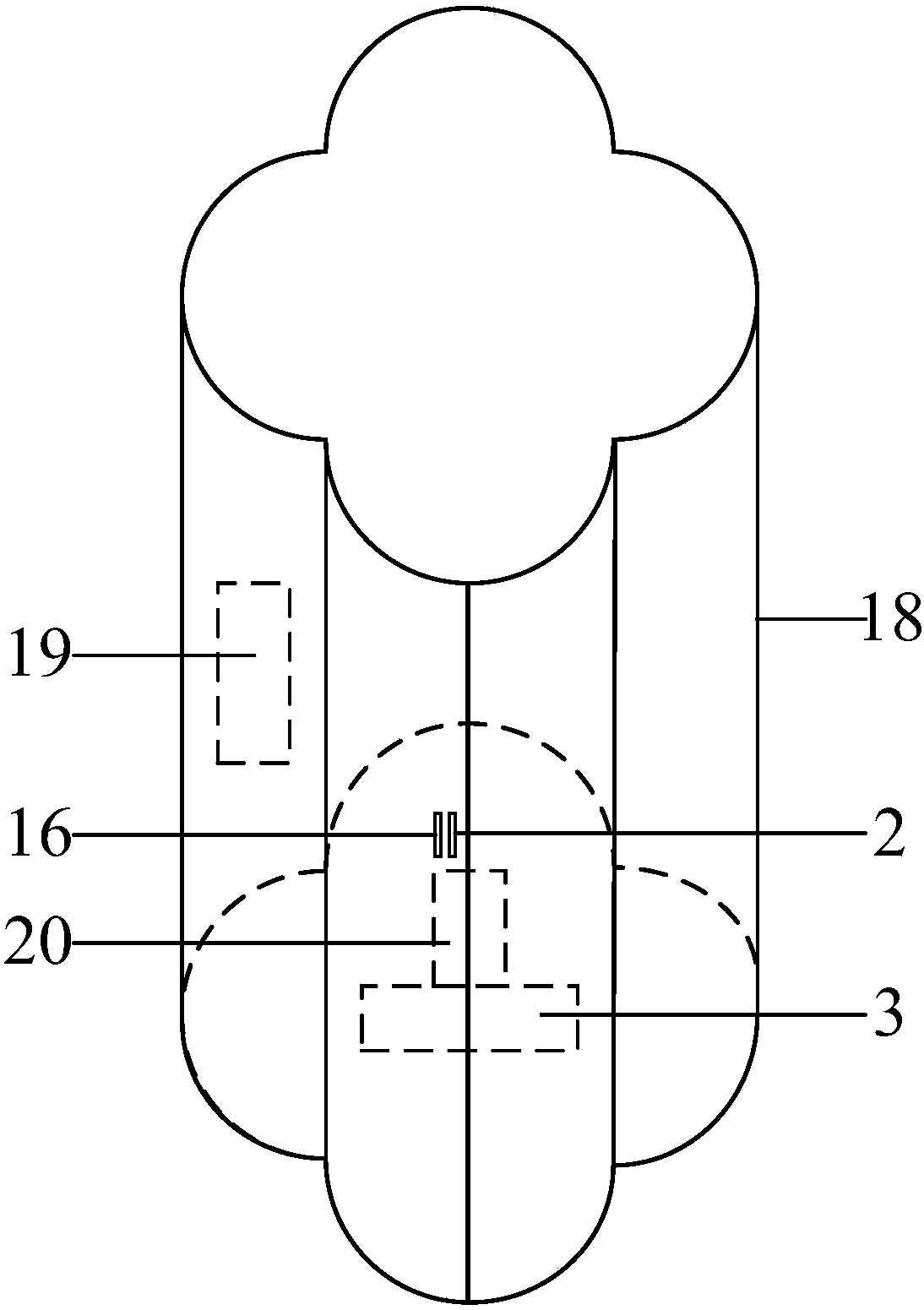

[0044] Embodiment 1: as Figure 1-4 As shown, the present invention provides a 3D printer for printing a glass body, including a printer, a scanner 5, a melting kiln 6, a raw material supply tank 7, a cyan pigment bucket 8, a magenta pigment bucket 9 and a yellow pigment bucket 10;

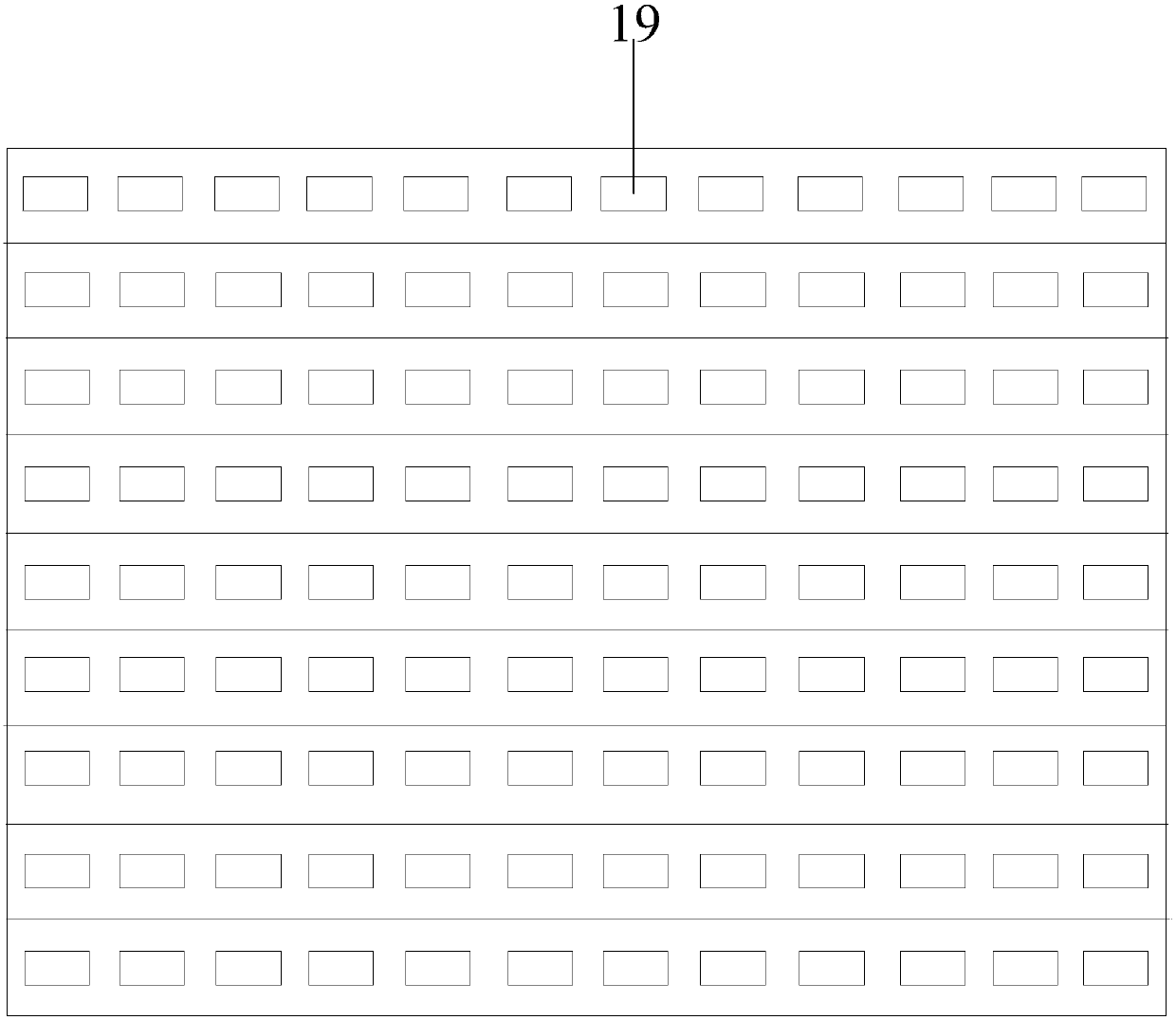

[0045] The printer includes a body 1 and a printing chamber 18. The body 1 is equipped with a library, and graphics to be printed can be selected from the library. The body 1 serves as the control system and computing system of the entire printer, controlling the precise and automatic operation of the entire 3D printer. The body 1 is provided with a control panel 4, and the control panel 4 is provided with control buttons 4-1 of different colors.

[0046]A nozzle 2 is arranged at the bottom of the body 1, and a bottom plate 3 is arranged under the nozzle 2 corresponding to the nozzle 2. The nozzle 2 squeezes the glass water out onto the bottom plate 3 to form a workpiece 20 to be processed. A las...

Embodiment 2

[0053] Embodiment 2: as Figure 5 As shown, the present invention provides a printing method of a 3D printer, comprising:

[0054] S101, adding waste glass to a melting furnace for melting, heating to 1850-1950°F, and generating raw materials required for printing;

[0055] S102. Input the graphics to be printed through the scanner, if the graphics are stored in the library of the body, then directly call the graphics; if the graphics are not stored in the body, scan the printed object through the scanner, scale it down and save it Body gallery;

[0056] S103. The machine body calculates the amount of raw materials required according to the input graphics and the size and thickness of the printed object, and controls the amount of raw materials flowing from the melting kiln into the raw material supply tank through the first valve; the amount of raw materials added to the raw material supply tank 7 is large The amount of raw materials required for printing graphics is 5-10ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com