Novel two-for-one twister

A two-for-one twisting machine and equipment technology, applied in the direction of textiles and papermaking, can solve the problems of restricting the performance of single-spindle twisting motors, large quantities, etc., and achieve the effects of high efficiency, energy saving, high efficiency, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

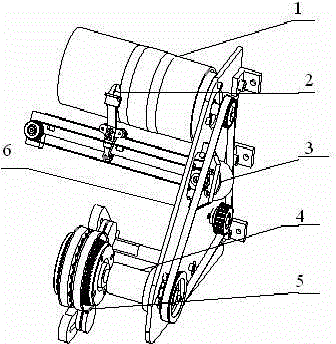

[0012] see figure 1 As shown, the present invention includes a friction drum 1, a yarn guide nozzle 2, a traverse motor 3, a winding motor 4, an overfeed roller 5, and a body shell 6. The friction roller 1 is located at the upper end of the body casing 6, and the friction roller 1 is provided with a rolling bearing structure, which is connected with the body casing 6. The friction roller 1 is embedded with an outer rotor motor, and the right end of the friction roller 1 is provided with a horizontal The moving motor 3 is provided with a cross-bar pulley structure on the traverse motor 3, and the yarn-guiding ceramic mouth 2 is provided on the said cross-bar pulley structure, and the yarn-guiding porcelain mouth 2 is provided with a pulley traverse structure, and the front of the lower end of the body shell 6 is provided with There is a winding motor 4, the right end of the winding motor 4 is connected to the body shell 6, the left end of the winding motor 4 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com