Desilting canal

A channel and bend technology, applied in the field of sediment treatment in water conservancy projects, can solve the problems of easy deposition of coarse sand in long-distance transportation, large land occupation of sedimentation tanks, and difficulty in reuse, etc. Small digging volume and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

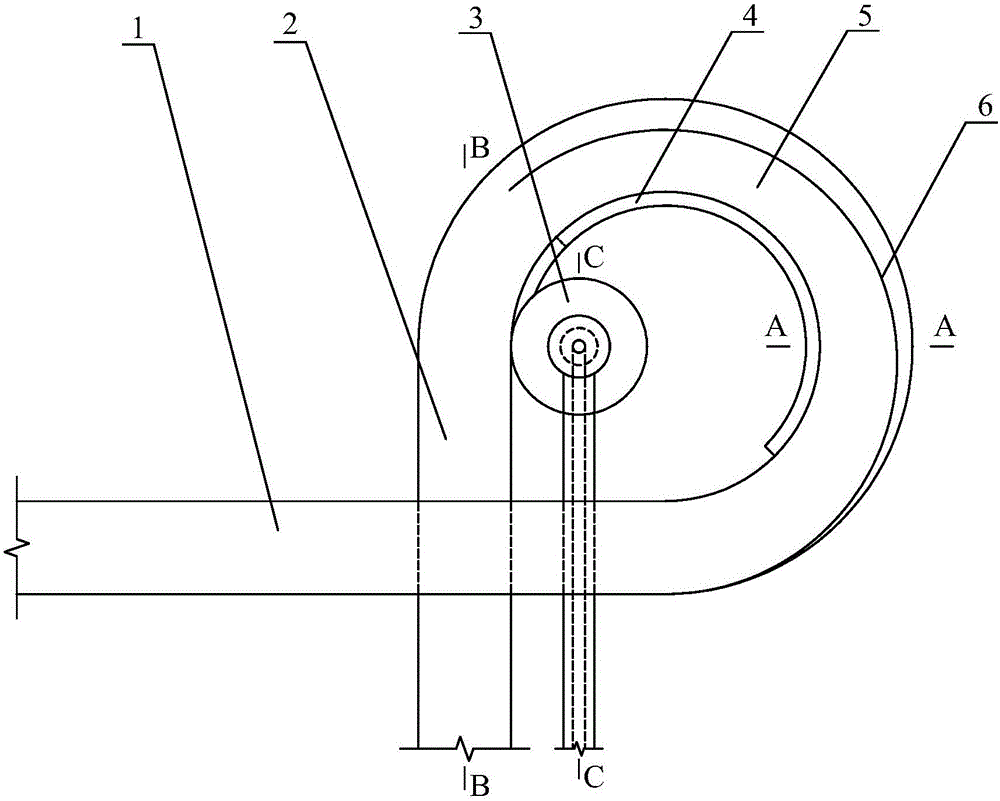

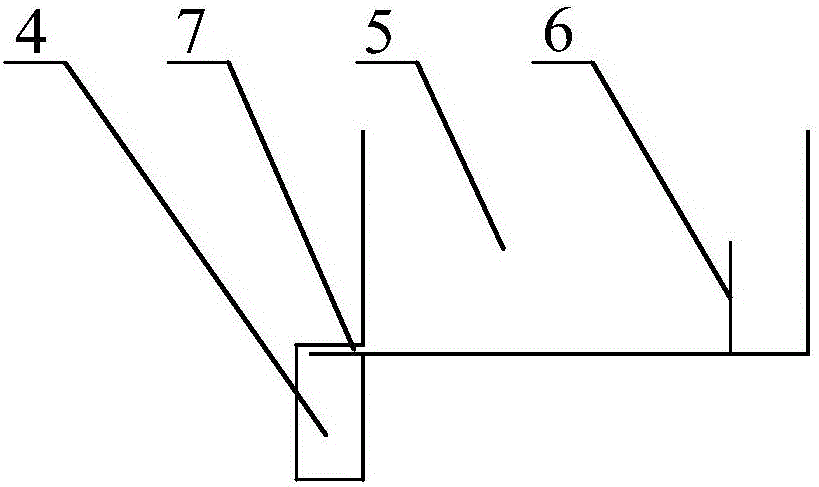

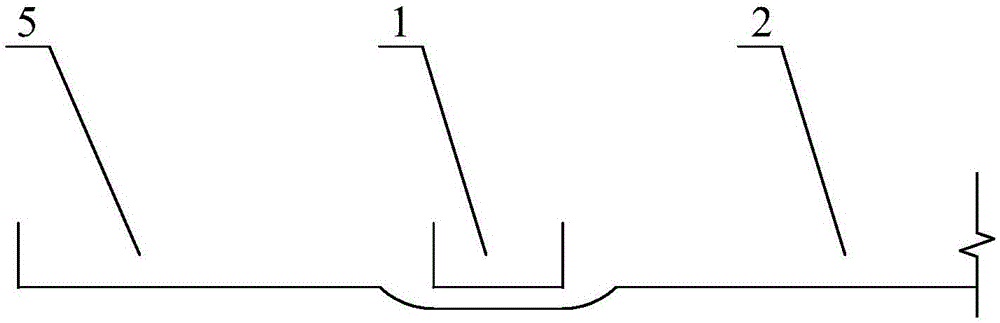

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Such as Figure 1~4 As shown, the cross section of the water inlet channel 1 is rectangular, the water inlet channel 1 is linear in the longitudinal direction, and the length of the water inlet channel 1 is more than 10 times its width. At the end of the water inlet channel 1, there is a bend 5 connecting 270°. The cross section of the bend 5 is a rectangle, and an arc-shaped overflow deflector 6 is arranged in the bend 5. The height of the overflow deflector 6 is curved. 0.23 times of the width of the road 5, a slit 7 is opened at the bottom position of the inner wall of the bend 5, the central angle of the slit 7 is 180 °, and the height of the slit 7 is 1 / 100 times of the width of the bend 5. Connect the outlet channel 2 at the end of the bend 5, the outlet channel 2 is straight in the longitudinal direction, and the outlet channel 2 passes u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com