Adding and stirring machine for filling dredged sediment of construction projects and construction method thereof

A technology of construction engineering and mixing machinery, applied in construction, infrastructure engineering, soil protection, etc., can solve the problems of high cost, complicated operation, insufficient mixing of dredging mud and curing agent, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

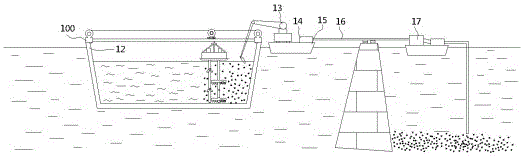

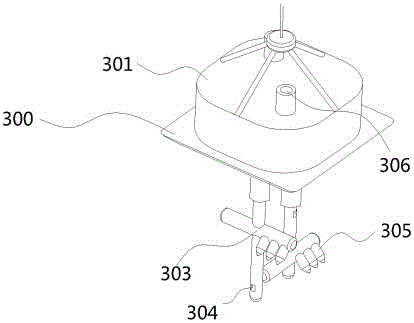

[0042]It is used for filling and dredging mud filling and mixing machinery in construction engineering, including vertical guide rails 100 that can be spliced and lengthened installed on both sides of the barge. More than one transfer mechanism 200 that can move by itself is installed.

[0043] Transfer mechanism 200 comprises vehicle seat 207, is installed in vehicle seat 207 both sides and the driven wheel 206 that meshes with toothed track 101, winch wheel group one 208 is installed on vehicle seat 207, is installed on the winch wheel group by the motor 204 controlled by PLC One side 208 is externally connected with a driven wheel 205 that drives the driven wheel 206 to move.

[0044] Transverse guide rail 400 is connected between transfer mechanism 200, is installed in described transverse guide rail 400 and pulls movable winch wheel seat 202 by transfer mechanism 200, and winch wheel seat 202 is connected with winch wheel group one 208 on both sides with steel wire rope...

Embodiment 2

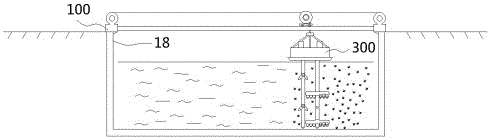

[0057] It is used for dredging mud filling and mixing machinery in construction projects, including vertical guide rails 100 installed on both sides of the foundation pit 18 that can be spliced and lengthened. More than one transfer mechanism 200 that can move by itself is installed.

[0058] Transfer mechanism 200 comprises vehicle seat 207, is installed in vehicle seat 207 both sides and the driven wheel 206 that meshes with toothed track 101, winch wheel group one 208 is installed on vehicle seat 207, is installed on the winch wheel group by the motor 204 controlled by PLC One side 208 is externally connected with a driven wheel 205 that drives the driven wheel 206 to move.

[0059] Transverse guide rail 400 is connected between transfer mechanism 200, is installed in described transverse guide rail 400 and pulls movable winch wheel seat 202 by transfer mechanism 200, and winch wheel seat 202 is connected with winch wheel group one 208 on both sides with steel wire rope 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com