Energy-dissipating steel column system with replaceable mild steel dampers

A mild steel damper, steel column technology, applied in building components, shockproof and other directions, can solve the problems of insufficient energy dissipation capacity, damage of connection parts, low bearing capacity, etc., to achieve fast construction speed, prevent structural layer yield, Good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

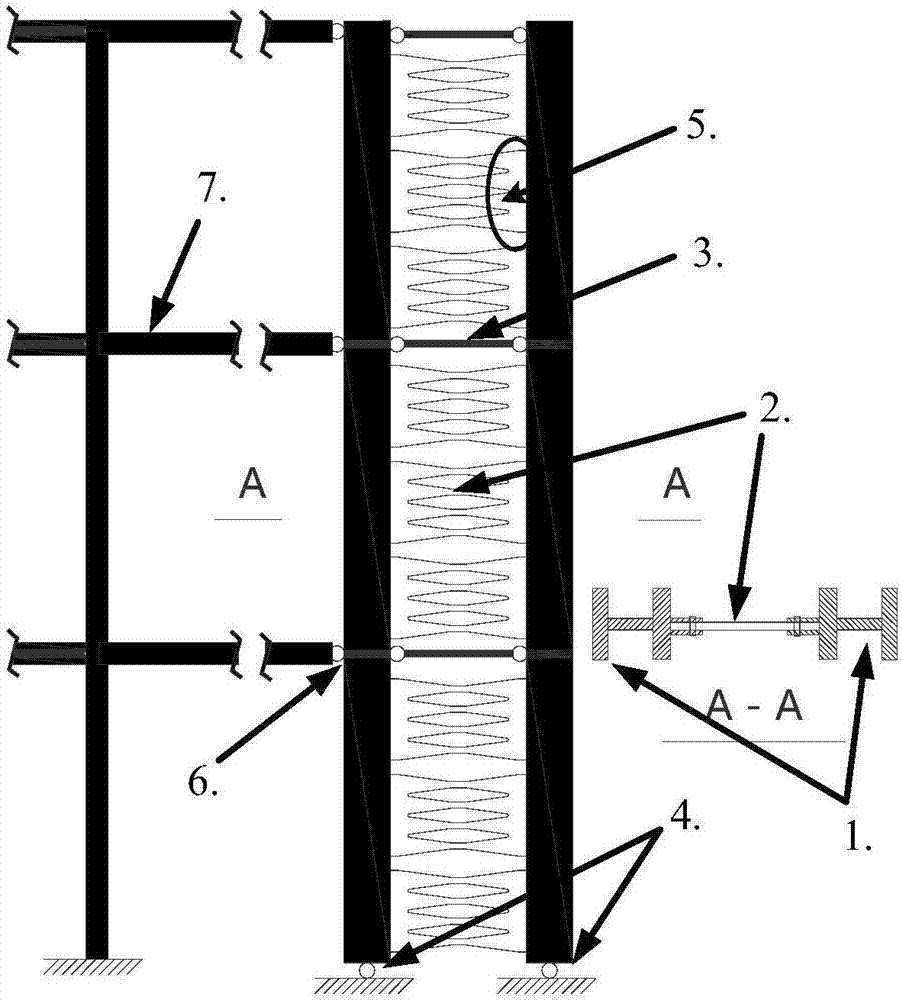

[0021] This example includes: column limb 1, multiple groups of mild steel dampers 2, rigid chain rod 3, hinge support 4, and mild steel damper installation nodes 5.

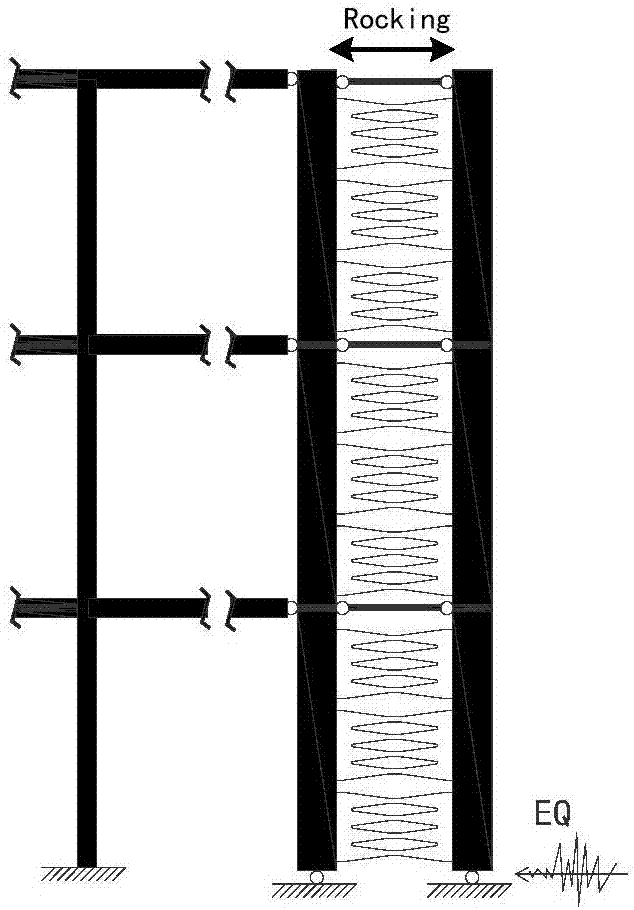

[0022] The system has two column limbs and mild steel dampers are vertically and continuously arranged between the columns. The rigid chain rod is hinged to the nodes of the two column limbs, the bottom of the column limbs is hinged to the foundation, and the column limb and the frame beam node are hinged6 .

[0023] The connection between the mild steel damper 2 and the two column limbs is the high-strength bolt connection of the cover plate with the function of restraining the out-of-plane buckling of the mild steel damper.

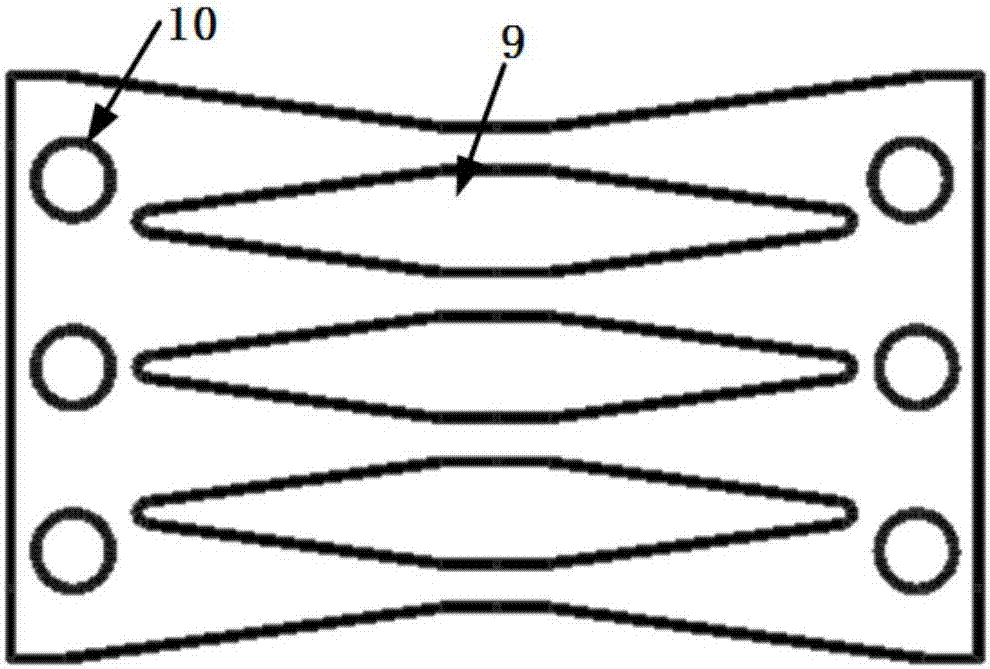

[0024] There are multiple horizontal diamond-shaped gaps in the middle of the mild steel damper along the vertical direction, and holes for high-strength bolts on the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com