Welding Method for Improving the Bearing Capacity of Aging Strengthened Aluminum Alloy Fusion Welding Joint

A fusion welding and aging strengthening technology, used in welding/welding/cutting items, welding equipment, metal processing, etc., can solve the problems of joint damage, weak mechanical properties, large area ratio, low joint strength and elongation, etc. Effect of Deformation Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

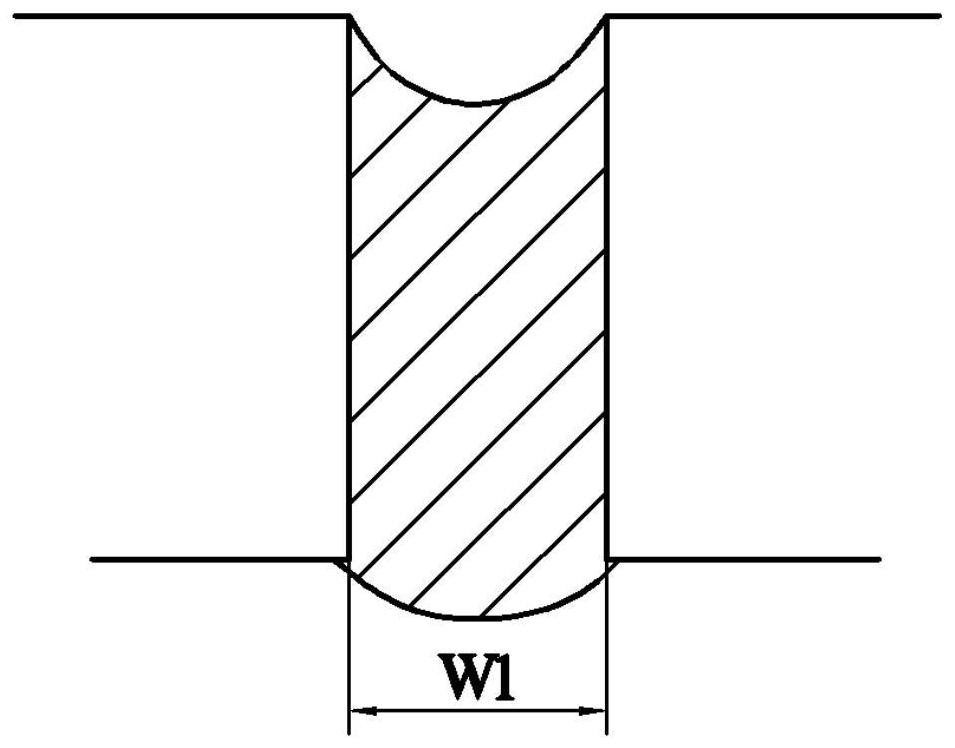

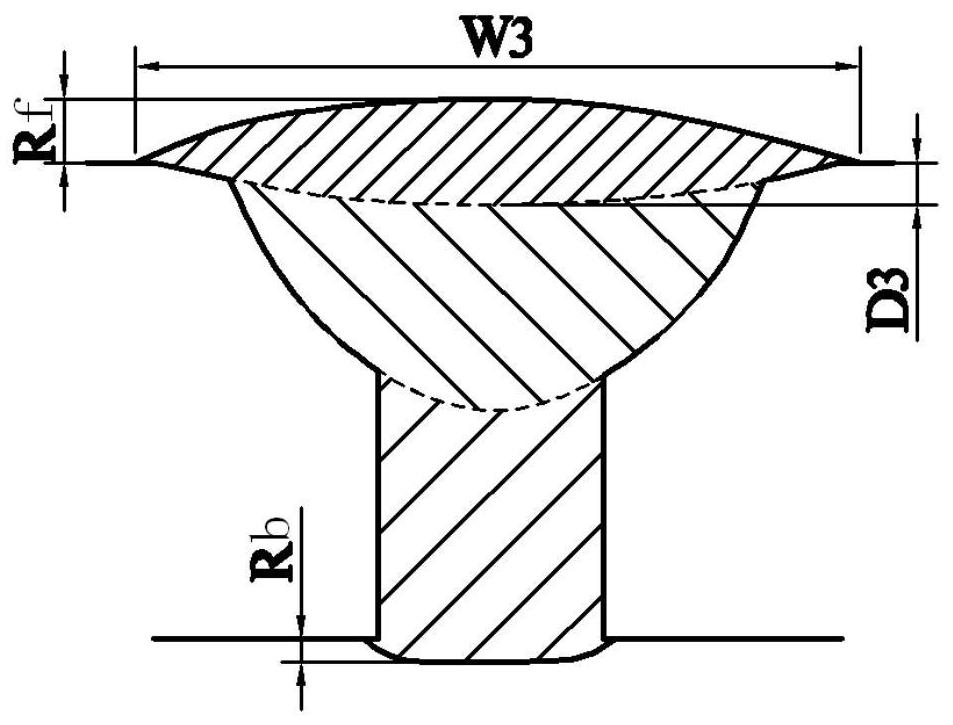

[0021] A welding method for improving the bearing capacity of an aging-strengthened aluminum alloy fusion welding joint, comprising the following steps: figure 1 as shown,

[0022] Step 1: Use variable polarity plasma arc welding or DC tungsten helium arc welding to perform back welding on (2219 high-strength aluminum alloy) plates with a plate thickness of δ=8 to 12mm, and do one-time penetration without opening the groove to form the first Layer welds, and the first layer welds are I-type welds, and the weld width is controlled at W1=0.6~0.8δ;

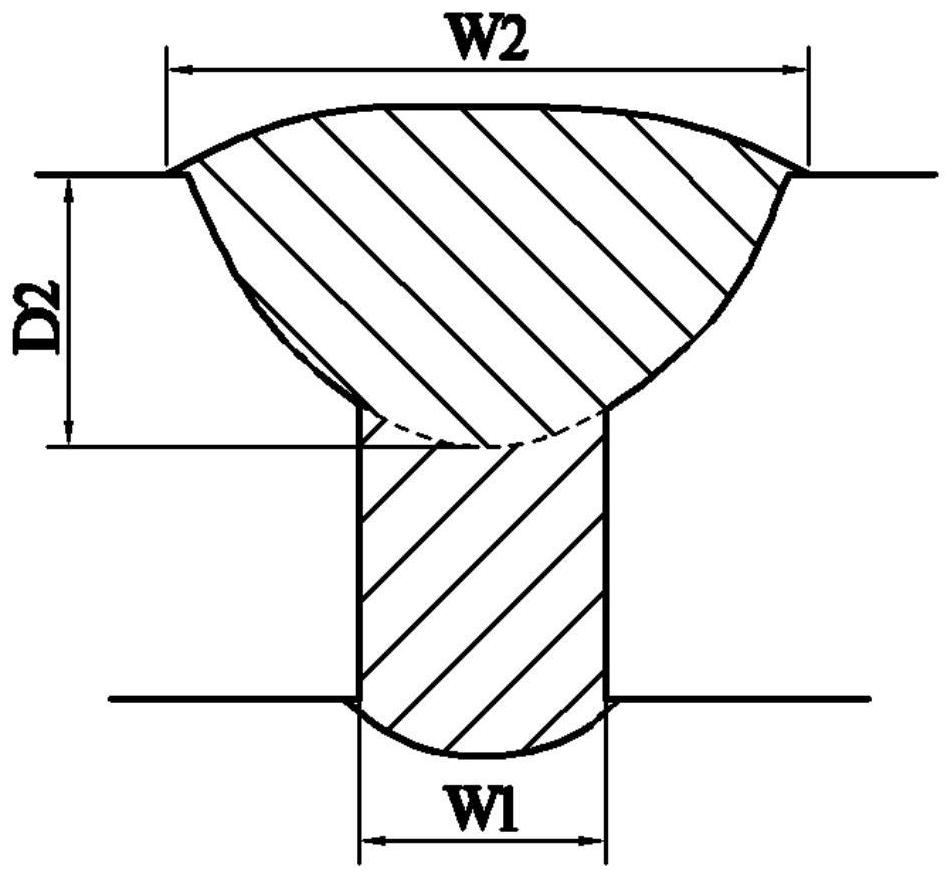

[0023] Such as figure 2 as shown,

[0024] Step 2: Use variable polarity tungsten argon arc welding or variable polarity melting electrode argon arc welding to cover the first layer of weld formed in step 1 to form a second layer of weld, and the second layer of weld For trumpet type, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com