Ball valve

A technology for ball valves and bonnets, which is applied to valve details, valve devices, valve shell structures, etc., can solve the problems of ball valves without filtering function, easy to produce gaps, easy to damage valve cores, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

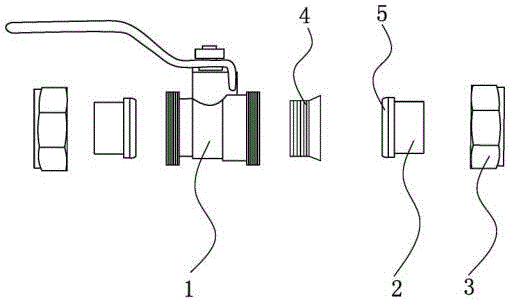

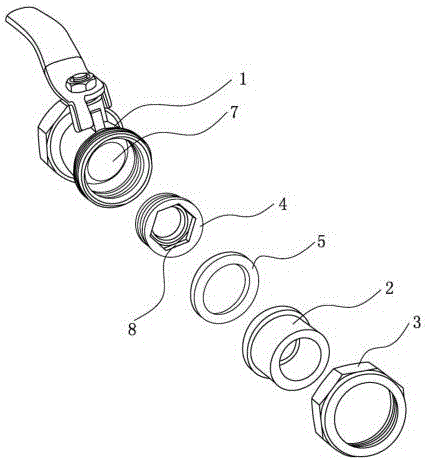

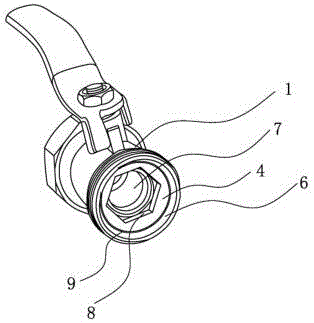

[0024] Such as figure 1 —3: A ball valve, including a ball valve main body 1, two tubular plastic connectors 2 and two fixing nuts 3, the inner cavity of the ball valve main body 1 is provided with a ball valve core 7, and the connectors pass through the fixing nuts. The caps are fixed on both ends of the ball valve body 1. The inner cavity of the ball valve body 1 is provided with a bonnet 4 located on one side of the ball valve core and fixing the ball valve core. The outside of the valve cap and the inside of the ball valve body 1 The walls are fixedly connected, and the rear end of the connector is provided with a sealing ring 5 that is tightly pressed at the gap 9 between the bonnet and the ball valve body 1 for sealing.

[0025] The present invention is a PPR double live ball valve, and the above-mentioned plastic connecting head 2 is made of material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com